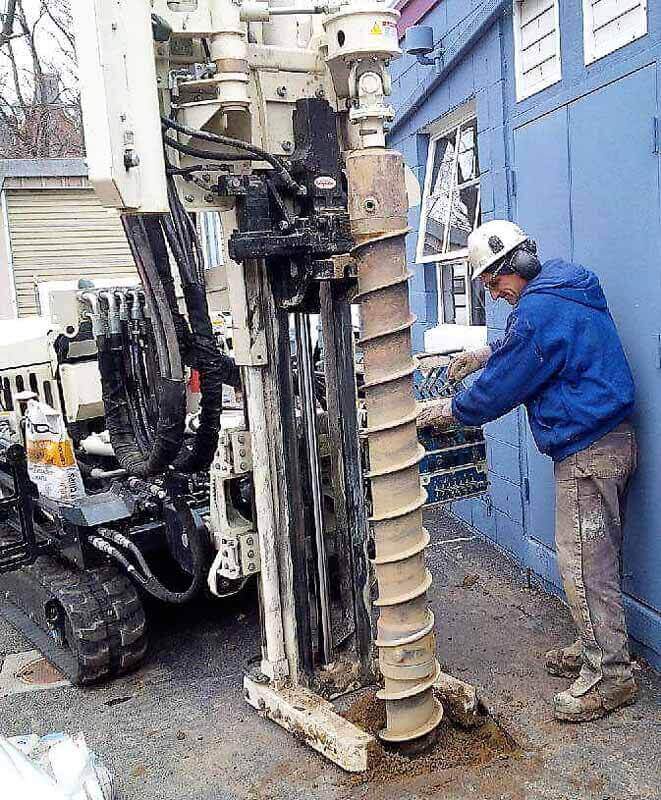

The 54DT is used to advance a series of 40 to 45 degree angled rods along a building to collect SP15 groundwater samples under the foundation.

Contributed by Rob Mores, Owner of Enviro-Dynamics in Hebron, IN

I’m proud to celebrate 20 years as a partner of Enviro-Dynamics, an environmental drilling company based in northwest Indiana. My wife, Amy, and I started the business in 1997. I had 10 years of experience in environmental contracting and consulting, and Amy had over six years sales and marketing experience. I would handle field operations while Amy manage the administrative and accounting functions.

We started out with a loan co-signed by my brother, and money liquidated from both of our 401Ks. That may not seem very risky; however, we had a one year old and two year old daughter, a mortgage payment on a new house, and all the other expenses of a young married couple.

In the beginning, my vision was simple: provide direct push services as an efficient and cost-effect alternative to traditional drilling methods. Our first machine was a Geoprobe® 4220 mounted on a Kawasaki Mule. Tooling included the basics: 1-in. and 1.25-in. probe rods with Large Bore and Macro-Core® soil samplers and mill-slot groundwater sampler.

Early on, it became very apparent that Geoprobe® was a great partner for our equipment and tooling needs. I was impressed with their continued innovation with both machines and tooling, and with their excellent customer support.

Within the first two years, we purchased our first 5400 truck-mounted machine and moved the 4220 from the Kawasaki Mule to a skid-loader capable of fitting through a 36-in. doorway. We converted the skid-loader from gasoline to propane to target limited access work, both indoors and out. However, we found there was a greater demand for outside limited access work requiring a more versatile ATV type rig.

In 1999, we sold the 4220 skid-loader and purchased a Geoprobe® 54DT. The 54DT opened up many more opportunities due to its size, power, and versatility. It’s also the only machine that put us in the Geoprobe® 100 Club two different times! And talk about reliable ... we put well over 5,000 hours on the 54DT before we finally sold it!

In January 2000, we hired our first employee. We also added dual tube to our tooling options. The dual tube system was one of the best tooling additions Geoprobe® made to their lineup. Dual-tube sampling dramatically increased productivity, sample quality and integrity. Prior to dual tube, a decent day of continuous sampling was 125- to 175-linear feet in a day. Since then, we have completed over 300 linear feet per day using dual tube. There were even a few times we reached over 400 linear feet in a day. The larger dual tube rods also allow us to install small diameter wells using expendable cutting shoes and points.

In 2003, we purchased a 6610DT with an auger attachment which correlated into a sharp increase in our workload by having augering capabilities and the ability to use larger tooling.

In 2007, we added a 6600 truck with a PC111 carrier, and we had grown to three fulltime operators. Our capabilities had expanded to soil, soil gas, and groundwater sampling, installation of both standard and prepacked screened monitoring wells, injection services, and installation of 2-in. and 4-in. wells using hollow stem augers.

As years progressed, our 5400 resided in three different carrier trucks. We also added a 5410 and a 66DT. Except for our 6600/PC111, we have replaced all these rigs with a 6712DT and a 7822DT.

Today, we have four full-time operators, including myself, and our Geoprobe® fleet includes a 6600/PC111, 6712DT (low clearance cylinder), and 7822DT. We’re also working with Geoprobe® to refurbish our 6600 and mount it in a different truck.

I believe this lineup gives us options to work in a wide variety of environments including all-terrain settings, limited access, and low-overhead clearance without sacrificing power and performance.

Looking back 20 years ago, I would have never imagined that we would own a Geoprobe® machine capable of setting a double-cased well by turning 6.25-in augers to 25 feet, setting a 5-in casing, then advancing 3.75-in. probe rods through the casing to set a 2-in. prepacked screen well to 50 feet!

We have owned nine different Geoprobe® rigs over the past 20 years. Our decision to stay with Geoprobe® equipment and tooling has been one of the greatest keys to our success. The continued innovation and outstanding customer support from Geoprobe Systems® has helped us grow into the company we are today.

However, it’s obvious that machines can’t run on their own. Reliable and competent employees who operate our machines have also been been critical to our success. Mark Montalvo (with Enviro-Dynamics for 12 years), Steve Baltus (9 years), and Tobin Mielenz (5 years) are in the field every day representing our company well and servicing our client’s needs. I’m extremely confident in their knowledge and experience and their ability to operate the best equipment in the direct push industry.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

6712DT's size and power is perfect for not only soil sampling and landfill gas collection but also monitoring well installation.

ID: 14363 | Date:

Pairing the 6712DT with the 20CPT Press makes a system that is faster, safer, and more efficient.

ID: 14362 | Date:

Direct Image® Tooling provides high-quality data in the unforgiving geology of Alaska.

ID: 14360 | Date:

Primarily roaming within a 100-mile radius of Philadelphia, TRISTATE ENVIRONMENTAL MANAGEMENT SERVICES performs a broad range of environmental field services in New Jersey and Southeast Pennsylvania. Project Manager Ted Sobieski credits their “jack-of-all

ID: 13417 | Date:

Related Videos

Geoprobe® MD4 Display Overview

ID: 13461

ID: 1909

Geoprobe® 20CPT Press Overview

ID: 1897

ID: 1887

ID: 1955

ID: 1893