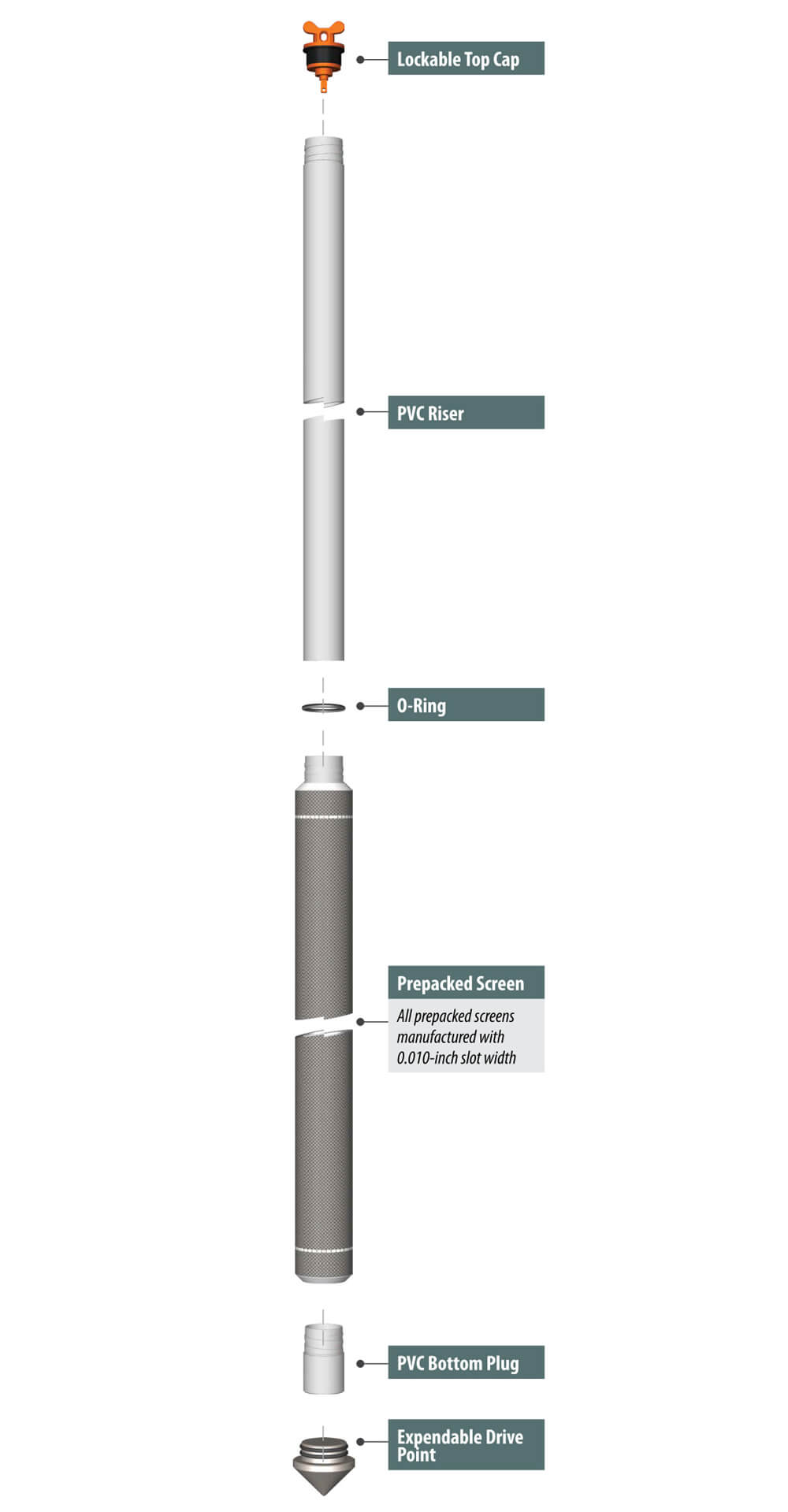

There's a lot of excitement in the Environmental Industry about Geoprobe® Prepacked Screen monitoring well designed for setting small diameter groundwater monitoring wells. Prepacked screens consist of a standard, slotted PVC well screen pipe surrounded by a stainless steel mesh. Sand is packed between the slotted PVC and the stainless steel mesh. Since the sand is packed around the slotted PVC before the well screen is installed, using prepacks guarantees sand will be located directly around the well screen. This makes groundwater monitoring well installation quicker and more efficient than traditional methods.

The 2-inch slim prepack uses a standard, 2 in. Schedule 40 slotted screen with a sand pack and 2.8 in. diameter stainless steel mesh screen on the outside. The 2.8 in. outside diameter can be used with 3.75 in. probe rods for an efficient combination of tooling for easy prepack installation.

Geoprobe® Monitoring Well Benefits Include:

- Quick and simple installation.

- Prepacked Screen designed with 20/40 grade environmental sand.

- No cuttings generated during installation.

- Meets all requirements of a RCRA well with exception of the smaller diameter.

- Permanent monitoring well installation with a Geoprobe® machine.

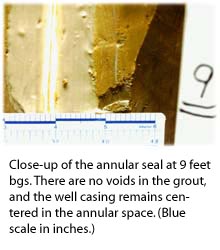

- Well seal and grouting meet EPA and ASTM D-5092 method requirements.

- Minimal disturbance of natural formation conditions.

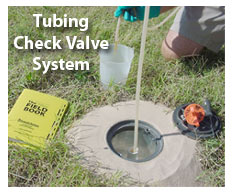

- Can be developed, purged, and sampled using inexpensive tubing check valve system.

- Minimal development and purge water generated for sampling reducing time requirements and disposal costs.

- Uses standard above-ground or flush-mount well protectors.

- Small diameter bladder pumps available for 1.0-inch wells

Installation

To install a groundwater monitoring well with these prepacks, probe rods are first driven to depth with a Geoprobe® probing machine. The well assembly is then lowered into the probe rod string with threaded PVC riser pipe. The 3.4 in. OD prepacked well assembly uses 2.0-inch Schedule 40 PVC riser pipe and is installed with 4.25-inch OD probe rods or through hollow stem augers. The 2.5-inch OD prepack well assembly uses 1.0-inch Schedule 40 PVC riser pipe and is installed with 3.25-inch OD probe rods. The smaller diameter prepacked well screen assembly uses 0.5-inch Schedule 80 PVC riser pipe and is installed with 2.25-inch OD probe rods.

Once the well assembly is lowered to the bottom of the probe rod string, the probe rods are retracted to a point above the screen. A sand barrier, installed directly above the well screen, prevents grout from entering the screens. This barrier can be created either by natural formation collapse (occurring during the initial probe rod retraction) or by gravity installation of fine-grade sand through the rod annulus. With the barrier in place, granular bentonite or bentonite slurry is then installed in the annulus to form a well seal.

Prepacked Screen Monitoring Wells from Geoprobe Systems® have been installed in various types of soil compositions including alluvial sediments consisting of clays, silts, and sands with fine to medium gravels at depths exceeding 60 feet. The time required for installation and grouting one of these wells varies from approximately one to four hours depending on the depth, site specific conditions, and experience of the operators.

Several steps can be followed to facilitate prepacked screen installation. Get your copy of one of the Monitoring Well SOPs for a detailed installation guide.

Prepack monitoring well installation breaks down into these steps:

- Understand the site's lithology

- Determine the appropriate prepack size

- Drive the probe rods

- Install the prepack(s) and riser

- Create the grout barrier

- Grout the well

- Develop the well

- Sample the well

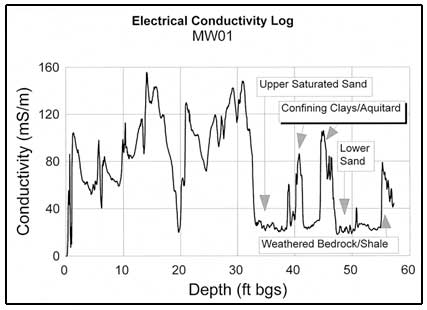

A conductivity log shows distinctive clay layers within saturated sands at a research project in Central Kansas. These are alluvial deposits. A thin, distinct sand lens is indicated at 20 feet with confining clays at 40 to 42 feet (12.2 to 12.8 m) and at 45 to 47 feet (13.7 to 14.3 m). Prior to setting the prepacked screen groundwater monitoring wells, a LB soil sample was taken from 45 to 47 feet bgs. The sample consisted of a dark, gray-black clay at the 45- to 47-foot interval correlating exactly with the conductivity log.

Dimensions

| 2.0 in. ID x 3.4 in. OD Prepacked Screen | ||||

| Slotted Pipe / Min. ID | Sand Pack | Length | Rod Size OD | Rod Size ID |

| 2.0 in. Sch. 40 PVC | 20/40 mesh sand | 60 in. | 4.5 in. | 3.75 in. |

| 0.010 in slots | factory packed | 1.5 m | 114 mm | 95 mm |

| 1.5 in. ID x 2.5 in. OD Prepacked Screen | ||||

| Slotted Pipe / Min. ID | Sand Pack | Length | Rod Size OD | Rod Size ID |

| 1.5 in. Sch. 40 PVC | 20/40 mesh sand | 60 in. | 3.25 in. | 2.625 in. |

| 0.010 in. slots | factory packed | 1.5 m | 82.5 mm | 66.7 mm |

| 1.0 in. ID x 2.5 in. OD Prepacked Screen | ||||

| Slotted Pipe / Min. ID | Sand Pack | Length | Rod Size OD | Rod Size ID |

| 1.0 in. Sch. 40 PVC | 20/40 mesh sand | 60 in. | 3.25 in. | 2.625 in. |

| 0.010 in. slots | factory packed | 1.5 m | 82.5 mm | 66.7 mm |

| 1.0 in. Sch. 40 PVC | field packed | 60 in. | 3.25 in. | 2.625 in. |

| 0.010 in. slots | 1.5 m | 82.5 mm | 66.7 mm | |

| 0.75 in. ID x 1.4 in. OD Prepacked Screen | ||||

| Slotted Pipe / Min. ID | Sand Pack | Length | Rod Size OD | Rod Size ID |

| 0.75 in. Sch.40 PVC | 20/40 mesh sand | 36 in. | 2.25 in. | 1.5 in. |

| 0.010 in. slots | factory packed | 1 m | 57 mm | 38 mm |

| 0.75 in. Sch.40 PVC | 20/40 mesh sand | 60 in. 1.5 m | 2.25 in. | 1.5 in. |

| 0.010 in. slots | factory packed | 57 mm | 38 mm |

ASTM Standards

Regulatory Compliance

Many state regulatory agencies have approved the use of prepacked screen wells installed by direct push methods, and more states are joining this movement on an almost daily basis. Likewise, many federal agencies have specified the installation of direct push prepacked screen wells for their permanent groundwater monitoring needs.

The U.S. Environmental Protection Agency has recommended the use of prepacked screens in their guidance document, "Expedited Site Assessment Tools for Underground Storage Tank Site, " (EPA, 1997). Geoprobe® brand prepacks meet the requirements of ASTM Standards for the installation of prepacked screen monitoring wells (ASTM D6725-01).

Current standards are available from ASTM (610-832-9500 or www.astm.org).

Advantages of Direct Push Monitoring Well

Conventional Method: Stripping the cuttings from the auger and removing cuttings to a waste container. Multiple barrels may be filled with cuttings by this method.

Geoprobe® Method: No cuttings generated; no disposal costs incurred. Probe rods are used to set the prepacked screen monitoring well. Saves time and labor costs.

- Produce no drill cuttings

- Use bottom-up grouting

- Have small well diameters

- Cause less disturbance to the natural formation

Why rely on Geoprobe® Prepack Monitoring Well?

Geoprobe® Prepacked Screen Monitoring Wells are the most cost-effective method for installing permanent monitoring wells. Why?

- Used for permanent groundwater monitoring sites across the country. Geoprobe® prepacks have been approved by many state regulators and federal agencies.

- Conform to the requirements of ASTM D6725-01 Standard Practice for Direct Push Installation of Prepacked Screen Monitoring Wells in Unconsolidated Aquifers.

- Geoprobe® Prepacks are ideal tools for low-flow sampling (minimal drawdown) procedures. Use with Geoprobe® bladder pumps for collection of high-integrity water quality samples.

- Available in a variety of lengths and diameters to suit your application.

- Manufactured using PVC and high-quality stainless steel to assure high-integrity samples. Vibro-filled sand pack is uniform in permeability from top to bottom. Touch it, push it, press it and see... Geoprobe® prepacks are dense and hard, packed into place.

- Saves time and labor costs... filter pack is factory installed. Uniformly densified sand pack will not settle during shipment. No more dropping sand through an auger. It's all here... all in one uniform package!

- Installation through cased probe hole provides high-integrity well construction and sample quality.

- Fully groutable design protects the environment.

- Minimal clearance between prepacked screen outside diameter and the installation rod inside diameter keeps the well screen and riser pipe centered in the well.

Sampling the Monitoring Well

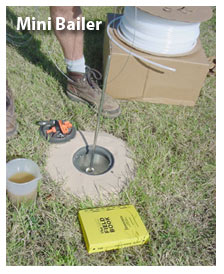

Prepacked screen groundwater monitoring wells can be sampled by several available methods (peristaltic pump, mini-bailer, tubing check valve, mechanical bladder pump, etc.) to obtain high-integrity water quality samples. The monitoring well also provides accurate water level measurements and can be used as observation wells during aquifer pump tests.

Find out more about the Mechanical Bladder Pump.

Related Published Research

Additional Links and Information

- Environmental Protection Article published September 2002.

- Expedited Site Assessment Tools for Underground Storage Tank Sites. EPA 510-B-97-001 US EPA Office of Underground Storage Tanks. Contact U.S. Gov. Printing Office at 202-512-1800 to request a copy. Website for the EPAs Office of Underground Storage Tanks (OUST) http://www.epa.gov/swerust1/directiv/index.htm.

- Recommended Guidelines for Multi-Level Sampling of Soil and Groundwater in Conducting Expedited Site Investigations at UST Sites in Connecticut. Contact: LUST Trust Fund Program, Connecticut DEP, 79 Elm St, Hartford CT. 06106.

- Seminars: Monitored Natural Attenuation for Groundwater. EPA/625/K-98/001 May be able to obtain copies of this from Gov. Printing Office or NTIS at 703-605-6000.

- To request to be on EPAs bioremediation mailing list call 513-569-7562.

For SOP's, technical papers, and other info about Geoprobe® Prepacked Screens click here.

Resources

Noticeable power difference in new 6712DT makes installing 2-inch groundwater monitoring wells to 25 feet feasible versus sending 7822DT.

ID: 12394 | Date:

6712DT provides power for PFAS investigation while Genuine Geoprobe® tooling and service from Southeast Service Center amplifies advantages.

ID: 5772 | Date:

So, why is groundwater monitoring important you ask? And what does 'direct push' have to do with it? And for that matter, what is 'direct push'?

ID: 5267 | Date:

With an inside diameter of 3.0 in., the 3.75 in. Probe Rods have an optimal casing combining ease of use for 2.0-in. Slim Prepack monitoring well installation,

ID: 5257 | Date:

Parts

To order parts or to get a quote, click here.

You will have the option to order immediately (pending payment) or get a quote.

0.75 in. ID x 1.4 in. OD x 60 in.

MN: 203095

0.75 x 60 in. (0.01-in. slot width)

MN: 203101

0.75 in. x 60 in.

MN: 201813

0.75 in.

MN: 202059

.75 in. Riser

MN: 600148

0.75 in. Riser, Non-locking, SCH 40

MN: 601079

0.75 in. Riser, Locking, SCH 40

MN: 601078

Quantity: 25

MN: 214070

2.25 in. Expendable Steel Point

2.45 in. OD

MN: 213788

1 in. ID x 2.5 in. OD x 60 in.

MN: 203096

1 in. x 60 in. (0.01-in. slot width)

MN: 202135

1 in. x 60 in.

MN: 202136

1 in.

MN: 202137

1 in. Riser, Locking, SCH 40

MN: 601071

1 in. Riser

MN: 114968

O-Ring (1.0 PVC Riser, SP16 Drive Head)

Quantity: 25

MN: 102256

3.25 in. Expendable Steel Point

3.57 in. OD

MN: 213798

1.5 in. ID x 2.5 in OD x 60 in.

MN: 203079

1.5 in. x 60 in. (0.01-in. slot width)

MN: 203080

1.5 in. x 60 in.

MN: 203081

1.5 in.

MN: 203082

1.5 in. Riser, Locking, SCH 40

MN: 601072

1.5 in. Riser

MN: 115080

Quantity: 25

MN: 102881

3.25 in. Expendable Steel Point

3.57 in. OD

MN: 213798

2 in. ID x 3.4 in. OD x 60 in.

MN: 206644

2 in. ID x 2.8 in. OD x 60 in. (for 3.75 rods)

MN: 220282

2 in. x 60 in.

MN: 104378

2 in. x 60 in. (0.01-in. slot width - no groove)

MN: 104852

2 in.

MN: 104397

2 in. Riser, Locking, SCH 40

MN: 601073

2 in. Riser

MN: 115052

4.5 in. Expendable Point Steel

5 in. OD

MN: 207735

Use with Slim Prepacks

MN: 219601

4 in. OD x 12 in. LG, Aluminum

MN: 601074

7 in. OD x 10 in. LG, Iron

MN: 601077

5/8 in. OD Tubing

MN: 214063

1/4 in. OD Tubing

MN: 214064

1/2 in. OD Tubing

MN: 214062

3/8 in. OD Tubing

MN: 214061

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601060

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601061

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601062

3/8 in. OD x 1/4 in. ID x 500 ft.

MN: 601063

1/2 in. OD x 3/8 in. ID x 500 ft.

MN: 601067

5/8 in. OD x 1/2 in. ID x 100 ft.

MN: 601068

75 lb. Bucket

MN: 213876

0.75 in. ID x 1.4 in. OD x 60 in.

MN: 203095

0.75 x 60 in. (0.01-in. slot width)

MN: 203101

0.75 in. x 60 in.

MN: 201813

0.75 in.

MN: 202059

.75 in. Riser

MN: 600148

0.75 in. Riser, Non-locking, SCH 40

MN: 601079

0.75 in. Riser, Locking, SCH 40

MN: 601078

Quantity: 25

MN: 214070

2.25 in. Expendable Steel Point

2.45 in. OD

MN: 213788

1 in. ID x 2.5 in. OD x 60 in.

MN: 203096

1 in. x 60 in. (0.01-in. slot width)

MN: 202135

1 in. x 60 in.

MN: 202136

1 in.

MN: 202137

1 in. Riser, Locking, SCH 40

MN: 601071

1 in. Riser

MN: 114968

O-Ring (1.0 PVC Riser, SP16 Drive Head)

Quantity: 25

MN: 102256

3.25 in. Expendable Steel Point

3.57 in. OD

MN: 213798

1.5 in. ID x 2.5 in OD x 60 in.

MN: 203079

1.5 in. x 60 in. (0.01-in. slot width)

MN: 203080

1.5 in. x 60 in.

MN: 203081

1.5 in.

MN: 203082

1.5 in. Riser, Locking, SCH 40

MN: 601072

1.5 in. Riser

MN: 115080

Quantity: 25

MN: 102881

3.25 in. Expendable Steel Point

3.57 in. OD

MN: 213798

2 in. ID x 3.4 in. OD x 60 in.

MN: 206644

2 in. ID x 2.8 in. OD x 60 in. (for 3.75 rods)

MN: 220282

2 in. x 60 in.

MN: 104378

2 in. x 60 in. (0.01-in. slot width - no groove)

MN: 104852

2 in.

MN: 104397

2 in. Riser, Locking, SCH 40

MN: 601073

2 in. Riser

MN: 115052

4.5 in. Expendable Point Steel

5 in. OD

MN: 207735

Use with Slim Prepacks

MN: 219601

4 in. OD x 12 in. LG, Aluminum

MN: 601074

7 in. OD x 10 in. LG, Iron

MN: 601077

5/8 in. OD Tubing

MN: 214063

1/4 in. OD Tubing

MN: 214064

1/2 in. OD Tubing

MN: 214062

3/8 in. OD Tubing

MN: 214061

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601060

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601061

1/4 in. OD x 3/16 in. ID x 500 ft.

MN: 601062

3/8 in. OD x 1/4 in. ID x 500 ft.

MN: 601063

1/2 in. OD x 3/8 in. ID x 500 ft.

MN: 601067

5/8 in. OD x 1/2 in. ID x 100 ft.

MN: 601068

75 lb. Bucket

MN: 213876