The Screen Point 15 groundwater sampling system was the most widely used direct push water sampling equipment for environmental groundwater investigations for several years. Since then, Geoprobe Systems® has retired the Screen Point 15 system and introduced the Screen Point 16 (SP16) system (1.6 in. OD screen sheath) which is designed for use under the more powerful GH60 hammer with the heavier 1.5 in. probe rods. These protected screen samplers have only five parts, including the grout plug, plus a few O-rings. Using either of these tools with O-rings on the rod fittings enables you to collect representative groundwater samples from a discrete interval using a bailer, bladder pump, or other device. The length of the screen exposed to the formation can be set from just a few inches to as much as 41-inches to let you select the sampling zone. Additionally, the same screens (Stainless Steel or PVC) can be used in both samplers. The grout plug at the base of the screen makes it possible to conduct bottom-up grouting with bentonite slurries or neat cement using any of the Geoprobe® GS Series grout machines. A PDF standard operating procedure (SOP) for the SP16 samplers is available for free to download.

SP16: Screen Point 16 Water Sampling Equipment

The SP16 Groundwater Samplers are used to collect groundwater samples from unconsolidated materials at depths ranging from near ground surface to over 100 feet below grade. The depth that can be reached with SP16 water sampling equipment is a function of the equipment and methods being used to advance the sampler (manual, static vehicle weight, or percussion probing), the formation being penetrated, and operator experience.

SP16 Advantages:

- Completely sealed during driving

- Stainless steel or PVC screen

- Actual interface samples

- 41-in. exposed screen length

- Fast recharge from formation

- Samples recovered using Tubing Check Valve, Mini-bailer or 0.5 in. Bladder Pump

- Durable Drive Head and Corrosion Resistant Sampler Sheath

- Sample both dissolved compounds and NAPLs

- Built to withstand percussive probing

- Screen sheath forms mechanical annular seal above the screen while sampling

How It Works

1. Driving

The assembled Screen Point 16 Groundwater Sampler is driven to the desired sampling depth using standard Geoprobe® rods.

2. Deployment

Extension rods are used to hold the screen in position while the rods and sheath are retracted. The screen sheath forms a mechanical annular seal above the screen interval.

3. Sampling

The tubing check valve can be used to sample and measure NAPLs within the screen interval as well as sample groundwater. A small bladder pump may be used to collect high-integrity VOC samples.

4. Grouting

Abandonment grouting can be conducted to meet ASTM guidelines. A high-pressure grout pump is used to pump grout into the probe hole as the screen and rods are extracted using the rod grip pull assembly.

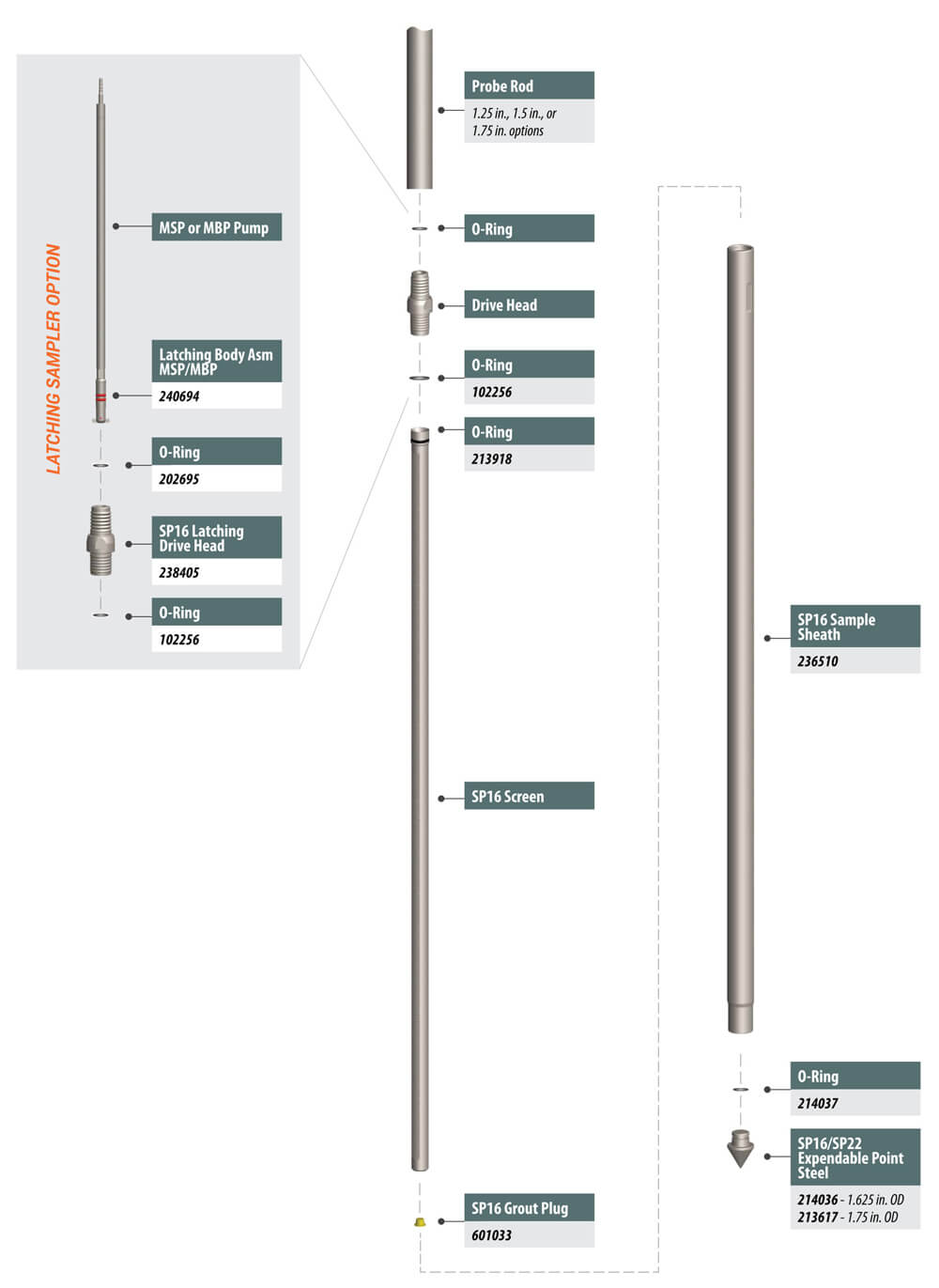

Latching SP16

The patented latching sampler allows the user to connect a pump, or other sample line, directly to the top of the downhole SP sampler. This isolates the SP sampler from water in the rod string above the sampler, thereby assuring sample integrity.

*Groundwater latching sampler option manufactured under U.S. Patent 12,013,317

We could go through 100 feet of water with confidence of the discrete nature of the sample, important because the detectable carcinogenic rate of PFAS is so low you have to be certain there's no cross contamination.

Mark Zork, President, Technical Drilling Services

Resources

Tool String Diagram

To use the latching sampler with the SP16 Groundwater Sampler, be sure to select the SP16 Latching Drive Head (MN 238405) when you purchase this system. When operating the mechanical syringe or bladder pump within this sampler, Geoprobe® recommends using the mechanical actuator (MN 214106) for sample collection. Latching groundwater sampling system patent pending.

Parts

To order parts or to get a quote, click here.

You will have the option to order immediately (pending payment) or get a quote.

1.25 Pin, 1.63 in. OD

MN: 211776

1.5 Pin, .625 in. Bore

MN: 202633

1.5 Pin, .5 in. Bore

MN: 203262

1.75 Pin, .5 in. Bore

MN: 223178

Stainless Steel

MN: 214027

PVC, Recoverable

MN: 214028

0.65 in. ID, 0.010 Slot, PVC, Disposable

MN: 202821

Quantity: 25

MN: 601033

MN: 236510

SP16/SP22 Expendable Point Steel

1.625 in. OD, Quantity: 25

MN: 214036

SP16/SP22 Expendable Point Steel

1.75 in. OD, Quantity: 25

MN: 213617

Quantity: 25

MN: 213771

Quantity: 25

MN: 202695

Quantity: 25

MN: 220387

O-Ring (1.0 PVC Riser, SP16 Drive Head)

Quantity: 25

MN: 102256

O-Ring (MC5 Point, DT22 Point, SP16 SS Screen)

Quantity: 25

MN: 213918

O-Ring (SP15/SP16 Expendable Point)

Quantity: 25

MN: 214037

3/8 in. OD x 1/4 in. ID x 100 ft.

MN: 600144

3/8 in. OD x 1/4 in. ID x 500 ft.

MN: 601063

3/8 in. OD Tubing

MN: 214061

MN: 214031

0.4" OD X 20"

MN: 214056

MN: 214058

Replacement Check Balls (3/8 Check Valve)

Quantity: 5

MN: 214057

O-Ring Service Kit (SP16 1.5 Rod)

MN: 202797

MN: 240694

Quantity: 10

MN: 239184

Quantity: 10

MN: 240695

Quantity: 20

MN: 239716

1.5 Pin

MN: 238405

MBP/MSP Check Ball Stainless Steel

Quantity: 10

MN: 103212

60 in., Stainless Steel

MN: 201352

48 in., Stainless Steel

MN: 213833

MN: 213832

MN: 213837

MN: 213836

MN: 213838

MN: 213839

MN: 214029

1.25 Pin, 1.63 in. OD

MN: 211776

1.5 Pin, .625 in. Bore

MN: 202633

1.5 Pin, .5 in. Bore

MN: 203262

1.75 Pin, .5 in. Bore

MN: 223178

Stainless Steel

MN: 214027

PVC, Recoverable

MN: 214028

0.65 in. ID, 0.010 Slot, PVC, Disposable

MN: 202821

Quantity: 25

MN: 601033

MN: 236510

SP16/SP22 Expendable Point Steel

1.625 in. OD, Quantity: 25

MN: 214036

SP16/SP22 Expendable Point Steel

1.75 in. OD, Quantity: 25

MN: 213617

Quantity: 25

MN: 213771

Quantity: 25

MN: 202695

Quantity: 25

MN: 220387

O-Ring (1.0 PVC Riser, SP16 Drive Head)

Quantity: 25

MN: 102256

O-Ring (MC5 Point, DT22 Point, SP16 SS Screen)

Quantity: 25

MN: 213918

O-Ring (SP15/SP16 Expendable Point)

Quantity: 25

MN: 214037

3/8 in. OD x 1/4 in. ID x 100 ft.

MN: 600144

3/8 in. OD x 1/4 in. ID x 500 ft.

MN: 601063

3/8 in. OD Tubing

MN: 214061

MN: 214031

0.4" OD X 20"

MN: 214056

MN: 214058

Replacement Check Balls (3/8 Check Valve)

Quantity: 5

MN: 214057

O-Ring Service Kit (SP16 1.5 Rod)

MN: 202797

MN: 240694

Quantity: 10

MN: 239184

Quantity: 10

MN: 240695

Quantity: 20

MN: 239716

1.5 Pin

MN: 238405

MBP/MSP Check Ball Stainless Steel

Quantity: 10

MN: 103212

60 in., Stainless Steel

MN: 201352

48 in., Stainless Steel

MN: 213833

MN: 213832

MN: 213837

MN: 213836

MN: 213838

MN: 213839

MN: 214029