Perform CPT Test to Obtain Geotechnical Data Commonly Needed for Construction Purposes

A Cone Penetration Test (CPT) is commonly used to determine the subsurface stratigraphy in situ (in place) and to estimate geotechnical parameters of the materials present. Geotechnical engineers typically use a CPT test to determine the necessary construction requirements for infrastructure – roadbeds, bridges, buildings. Due to the sensitive electronics inside the cone, it must be pushed to depth by static push methods. The CPT test method consists of pushing an instrumented cone into the ground at a controlled 2 cm/sec push rate. Common measurements being collected are cone tip pressure, sleeve friction, pore pressure and tilt angle. Additional sensors can be added like seismic, or other geo-environmental logging tools.

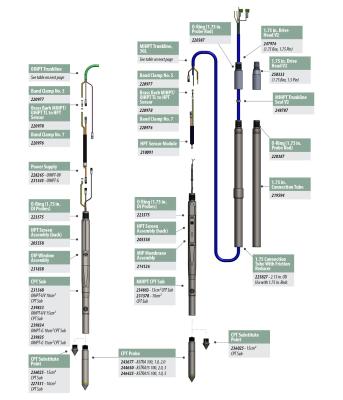

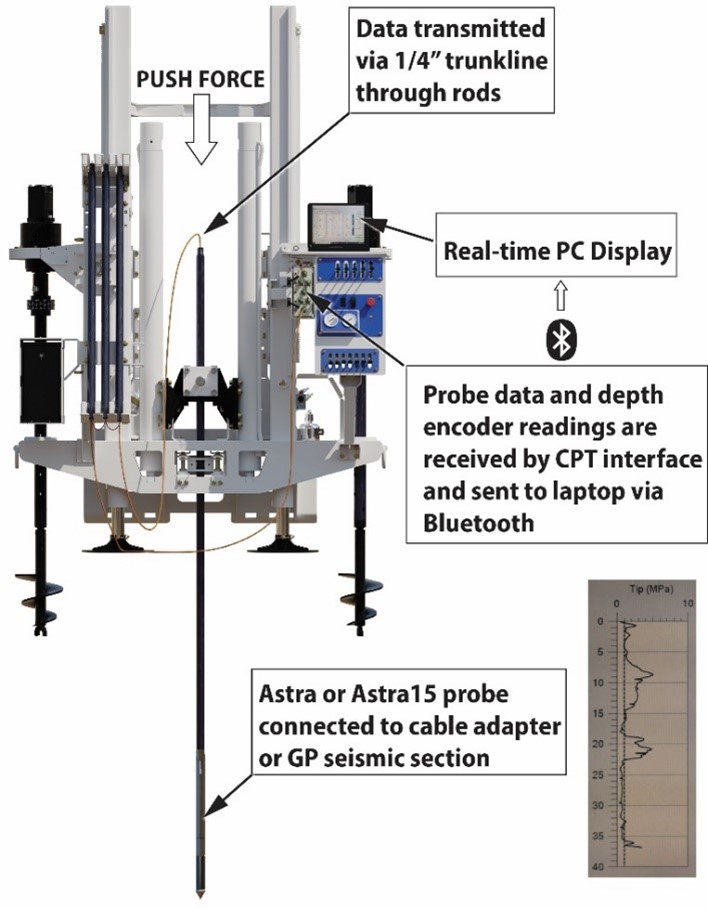

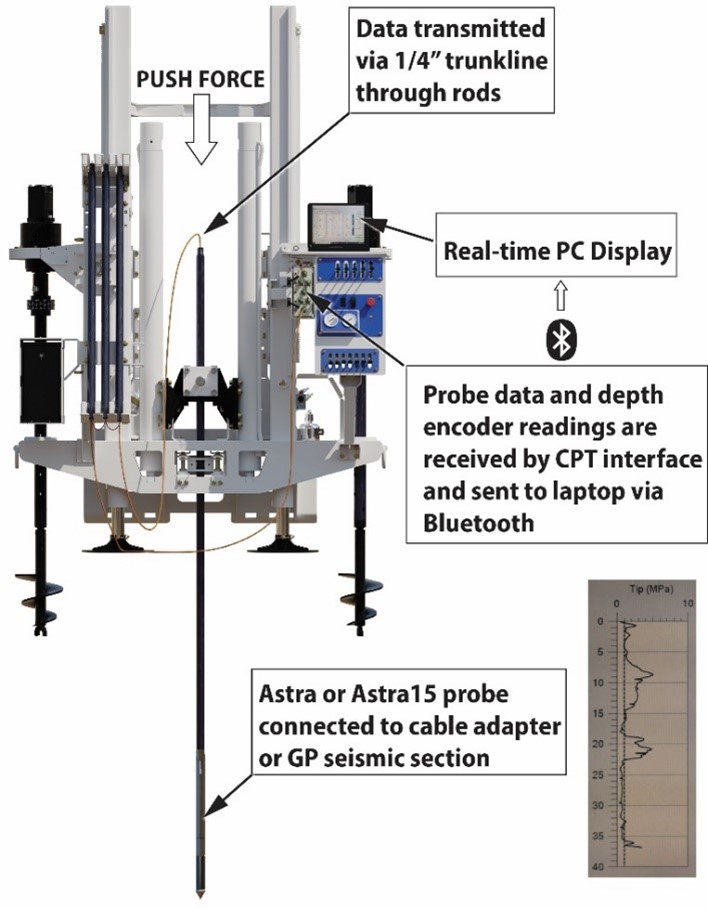

= Tool String Diagram (TSD)

CPT Overview

Having offered CPT equipment for decades, Geoprobe® has come to understand how innovative and ahead of their time the first generation of CPT Cones were. These independently gauged compression cones deliver high resolution digital data, representing soil strength while being pushed into the subsurface soil. Initially equipment was available in cordless form for CPT, later adding cabled option probes to save costs. Users would have the choice to operate CPT by cordless function, or by a cable running through the rods. Seismic could also be added as a module add-on to existing CPT Probes (cones).

Today we offer the next generation of CPT by Cabled ASTRA (made by Geoprobe) and Cordless NOVA (provided by our partners at Geotech AB). These instrumented cones record with higher resolution, are more robust in construction and have improved accuracy. Both lines of cones are offered in 10cm2 and 15cm2 sizes.

ASTRA CPT was developed by Geoprobe to provide CPT users with a cost-effective option for production CPT work. Made in-house allows for improved service and firsthand expert knowledge to help solve field concerns quickly. Specific focus was made to assure there is added strength in the cone construction. It operates at the same high resolution and provides the same accuracy of other CPT cones we provide. ASTRA is run by cable, utilizing a small diameter cord like the one used in the past. This can also accept seismic into the same system by just adding a few parts. It operates and records data through Geoprobe Software made in-house, allowing for changes and updates to meet customer needs.

The Geotech AB NOVA CPT system has always been unique in the geotechnical industry and is known for its cordless data transmission system: a constant digital stream of data is sent to the surface through the sounding rods. No cable through the rods is needed in the cordless setup. NOVA CPT operates by acoustic cordless function to transmit cone signal to the surface. Cordless CPT can add simplicity to a complex setup or arrangement by not dealing with a cord to add segmented rods into the ground.

For more than 25 years, Geoprobe Systems® has partnered with Geotech AB of Sweden to be the exclusive U.S. distributor for Geotech AB Cone Penetration Testing tools for geotechnical and environmental studies. Adding to the offering is the “made by Geoprobe” ASTRA CPT allowing us to become better experts and offer customers more options to solve their field challenges. We provide service and support for all CPT equipment sold by Geoprobe, with many large-scale improvements in our test equipment and processes. We provide cone calibrations to meet ASTM standards, as well as cone and component repair services.

The cordless or corded CPT cones can be pushed with a variety of push platforms to provide continuous data, repeatable penetration results, and cost savings over traditional boring and sampling methods.

Advantages of CPT

- There are many reasons for the widespread use of the CPT test method. Probably the most important is the In-Situ measurement... it measures soil properties in the right environment; in the soil as it is, where it is.

- The real-time, on-site interpretation of logs can be used to better dial in the soil type, water table and soil parameters for engineering design – ultimately saving project cost.

- Additionally, faster production rates when compared to conventional drilling and sampling result in a more cost-effective operation.

Figure 1:

Advancing CPT test with an anchored 6712 providing equal downforce of a 20 ton press

Principles of Operation

CPT test primary measurements include tip resistance(qc), sleeve friction(fs), and pore pressure(u). Tip resistance is a measurement of soil bearing capacity, sleeve friction is an indication of the soil cohesive strength commonly seen with clays, and pore pressure is related to the pressure generated as the cone is advanced as well as an indication to the amount of clay in the formation.

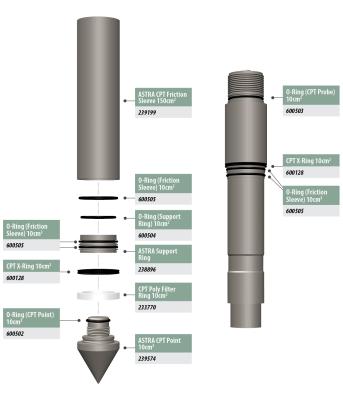

These probes are constructed of hardened alloy and tool steels. The probes consist of only a few parts; the gauged main body, tip, sleeve, and support ring. The upper end is threaded to connect to either the cable adapter or seismic section. The thread end piece at the top end of the probe is locked into place and is only intended to be removed for servicing at the factory.

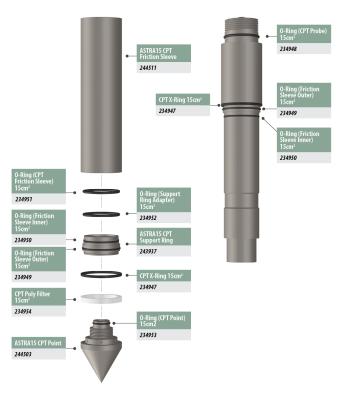

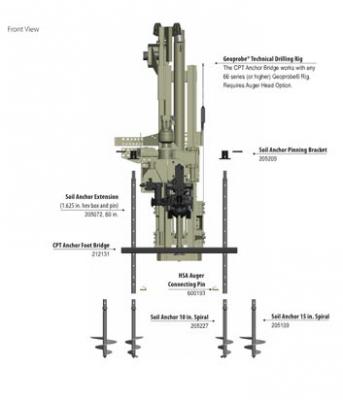

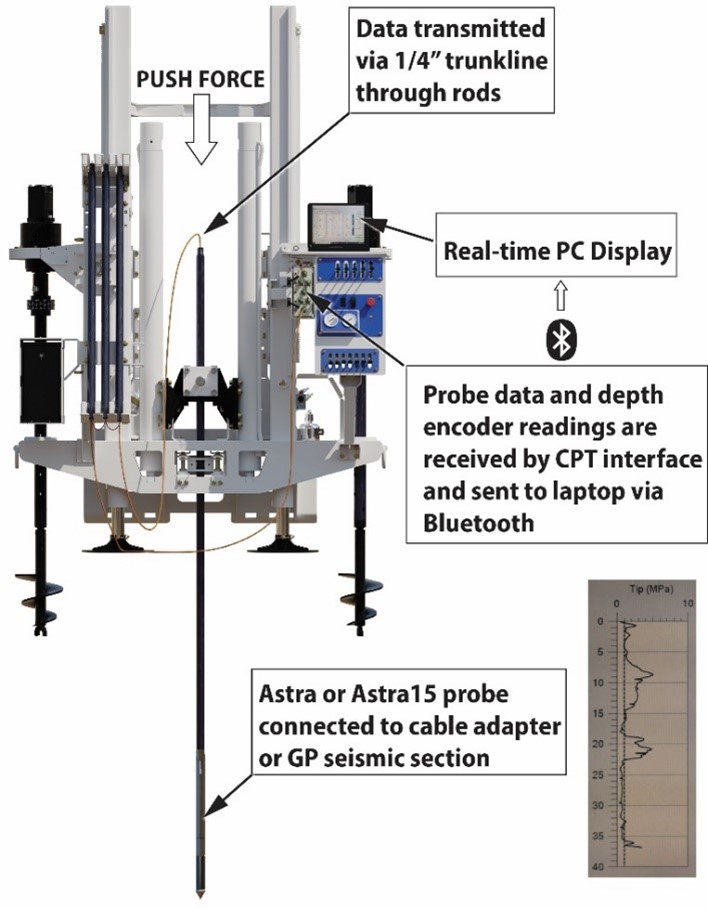

A cabled CPT system uses a cable adapter or seismic section mounted behind the CPT probe to acquire in-situ Tip (Qc), Sleeve (Fs), and Pore (U2) pressure measurements and transmit the data to an operator interface at ground surface, which then displays the data on the user’s field laptop. The overall system includes the CPT probe, a method of downhole communication that couples behind the CPT cone, a simple and cost effective 1/4 in. diameter cable, the surface CPT interface, and software for acquiring cone data.

The cordless CPT does not require a cable for data transmission to the surface. Inside the cone, the digital coded signal is converted to an acoustic signal and transmitted along the steel of the drill rods to the surface. Sound signals are received by a microphone at the surface which transmits the signal to a PC via a computer interface.

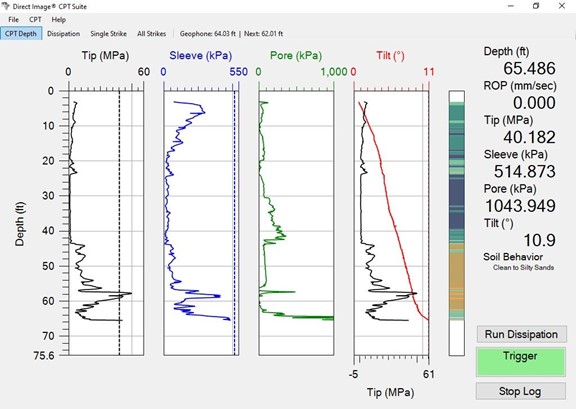

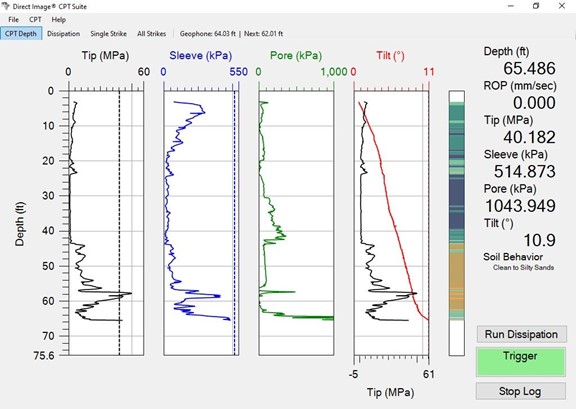

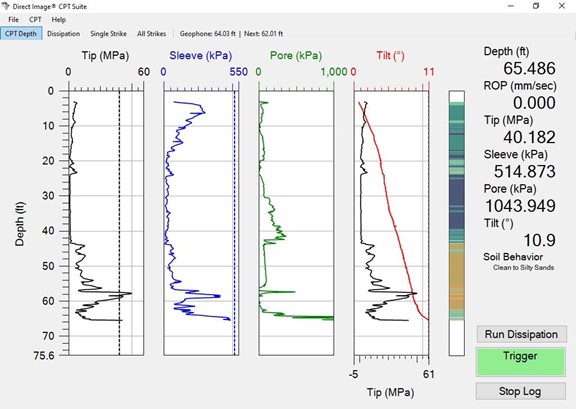

Figure 2::

CPT Operation

Example Logs

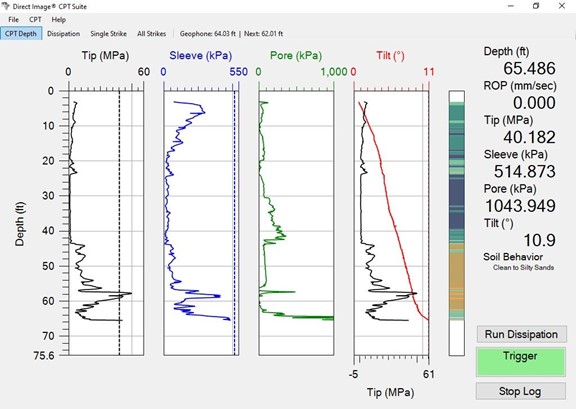

Figure 3:

Astra CPT field log using the DI CPT Suite software. The graphs include Tip (Qc), Sleeve (Fs), Pore pressure (U2), and the probe tilt angle. The right side of the screen displays the real time values of Depth, ROP, Tip, Sleeve, Pore Pressure, and Tilt angle as well as the real time Soil Behavior Type graph.

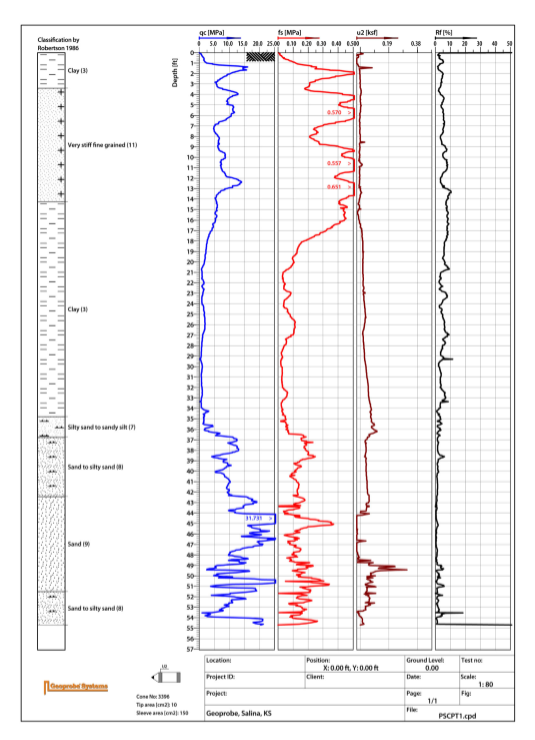

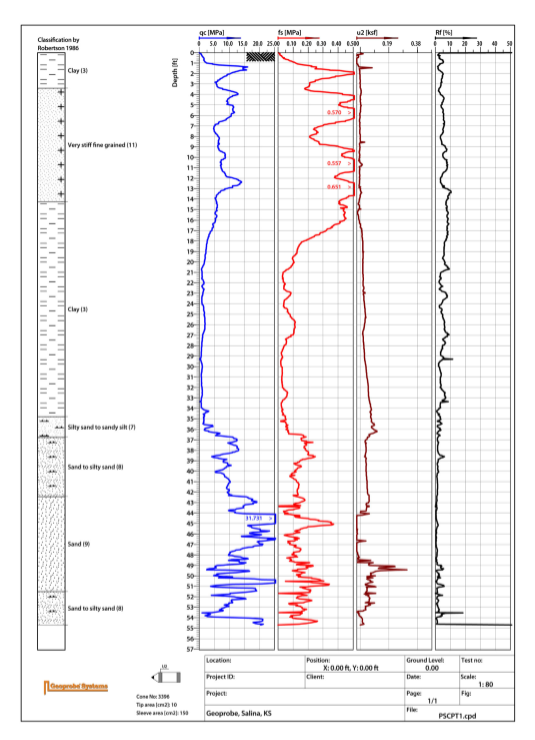

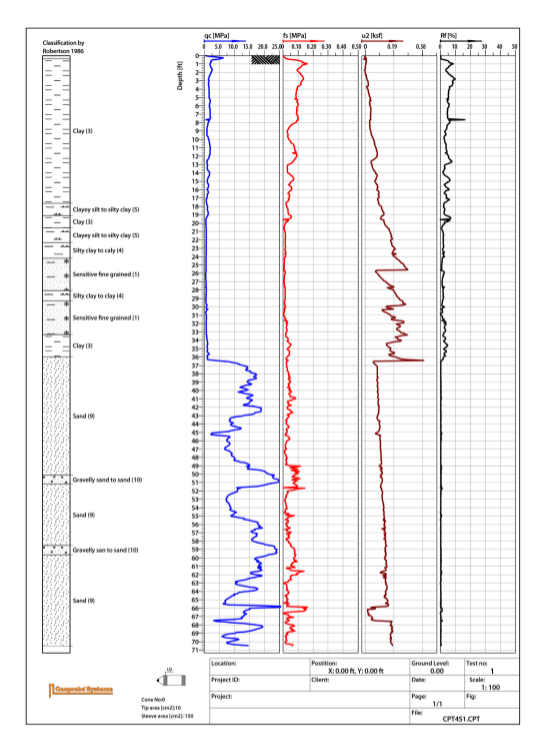

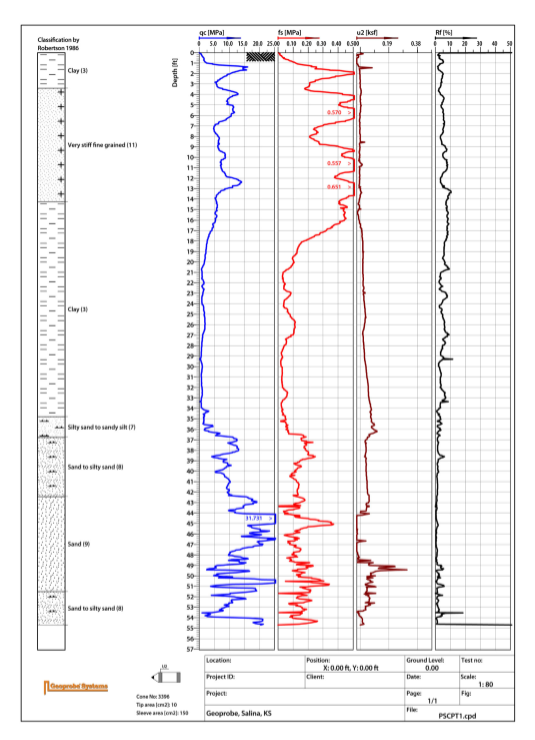

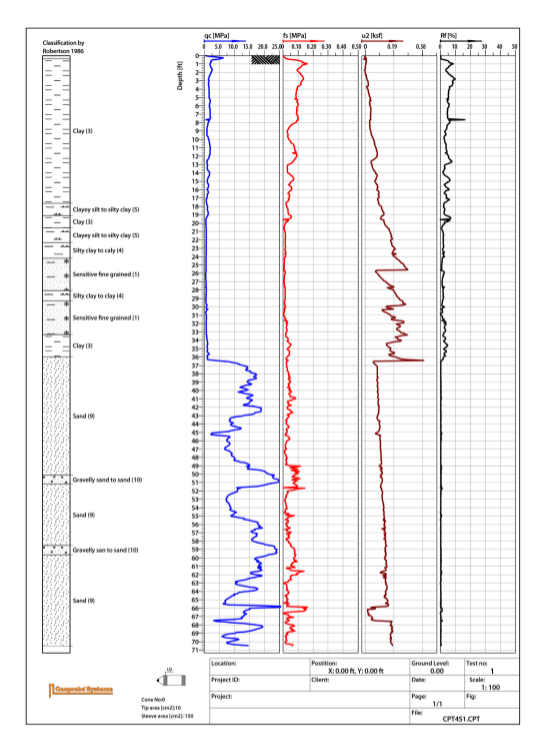

Figure 4:

CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (RF). Log easily shows the varying soil conditions encountered when pushing CPT in Saline County, KS. Log created using CPT-Pro (post-processing software).

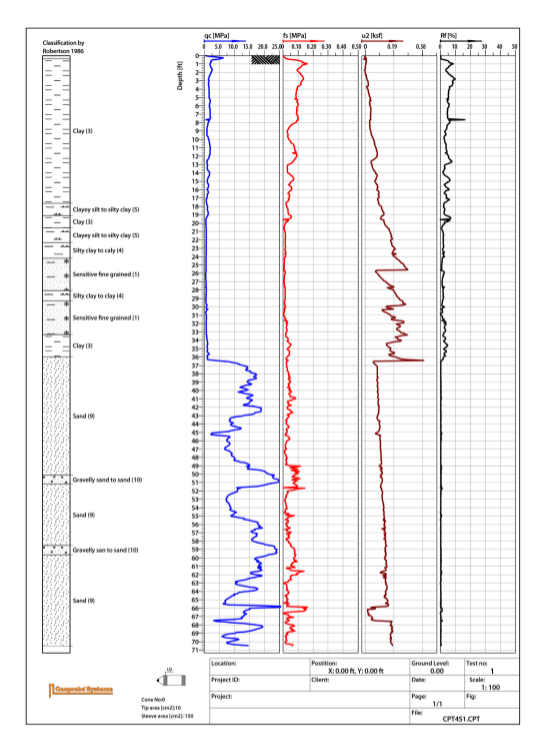

Figure 5:

CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (Rf). Log clearly shows the change from clay to sand in both tip pressure and pore pressure. Note the steady increase in pore pressure beginning at 36ft., indicating the probe encountered the water table. Log created using CPT-Pro (post-processing software).

CPT-Pro Sample Log

Data interpretation software, called CPT-PRO, completes your CPT investigation.

- Present CPT test results

- Identify soil types using the most common CPT soil behavior classifications

- Calculate and present Geotechnical parameters

- Standard penetration test (SPT) blow count correlation

- Undrained shear strength

- Relative density

- Friction angle

- Coefficient of lateral stress

- Constrained Module

Figure 6:

CPT-PRO Data Interpretation Software: Sample Log

Features & Options

Nova CPT Cone

Having offered CPT equipment for decades, Geoprobe® has come to understand how innovative and ahead of their time the first generation of CPT Cones were. These independently gauged compression cones deliver high resolution digital data, representing soil strength while being pushed into the subsurface soil. Initially equipment was available in cordless form for CPT, later adding cabled option probes to save costs. Users would have the choice to operate CPT by cordless function, or by a cable running through the rods. Seismic could also be added as a module add-on to existing CPT Probes (cones).

Today we offer the next generation of CPT by Cabled ASTRA (made by Geoprobe) and Cordless NOVA (provided by our partners at Geotech AB). These instrumented cones record with higher resolution, are more robust in construction and have improved accuracy. Both lines of cones are offered in 10cm2 and 15cm2 sizes.

ASTRA CPT was developed by Geoprobe to provide CPT users with a cost-effective option for production CPT work. Made in-house allows for improved service and firsthand expert knowledge to help solve field concerns quickly. Specific focus was made to assure there is added strength in the cone construction. It operates at the same high resolution and provides the same accuracy of other CPT cones we provide. ASTRA is run by cable, utilizing a small diameter cord like the one used in the past. This can also accept seismic into the same system by just adding a few parts. It operates and records data through Geoprobe Software made in-house, allowing for changes and updates to meet customer needs.

The Geotech AB NOVA CPT system has always been unique in the geotechnical industry and is known for its cordless data transmission system: a constant digital stream of data is sent to the surface through the sounding rods. No cable through the rods is needed in the cordless setup. NOVA CPT operates by acoustic cordless function to transmit cone signal to the surface. Cordless CPT can add simplicity to a complex setup or arrangement by not dealing with a cord to add segmented rods into the ground.

For more than 25 years, Geoprobe Systems® has partnered with Geotech AB of Sweden to be the exclusive U.S. distributor for Geotech AB Cone Penetration Testing tools for geotechnical and environmental studies. Adding to the offering is the “made by Geoprobe” ASTRA CPT allowing us to become better experts and offer customers more options to solve their field challenges. We provide service and support for all CPT equipment sold by Geoprobe, with many large-scale improvements in our test equipment and processes. We provide cone calibrations to meet ASTM standards, as well as cone and component repair services.

The cordless or corded CPT cones can be pushed with a variety of push platforms to provide continuous data, repeatable penetration results, and cost savings over traditional boring and sampling methods.

Advantages of CPT

- There are many reasons for the widespread use of the CPT test method. Probably the most important is the In-Situ measurement... it measures soil properties in the right environment; in the soil as it is, where it is.

- The real-time, on-site interpretation of logs can be used to better dial in the soil type, water table and soil parameters for engineering design – ultimately saving project cost.

- Additionally, faster production rates when compared to conventional drilling and sampling result in a more cost-effective operation.

Figure 1:

Advancing CPT test with an anchored 6712 providing equal downforce of a 20 ton press

CPT test primary measurements include tip resistance(qc), sleeve friction(fs), and pore pressure(u). Tip resistance is a measurement of soil bearing capacity, sleeve friction is an indication of the soil cohesive strength commonly seen with clays, and pore pressure is related to the pressure generated as the cone is advanced as well as an indication to the amount of clay in the formation.

These probes are constructed of hardened alloy and tool steels. The probes consist of only a few parts; the gauged main body, tip, sleeve, and support ring. The upper end is threaded to connect to either the cable adapter or seismic section. The thread end piece at the top end of the probe is locked into place and is only intended to be removed for servicing at the factory.

A cabled CPT system uses a cable adapter or seismic section mounted behind the CPT probe to acquire in-situ Tip (Qc), Sleeve (Fs), and Pore (U2) pressure measurements and transmit the data to an operator interface at ground surface, which then displays the data on the user’s field laptop. The overall system includes the CPT probe, a method of downhole communication that couples behind the CPT cone, a simple and cost effective 1/4 in. diameter cable, the surface CPT interface, and software for acquiring cone data.

The cordless CPT does not require a cable for data transmission to the surface. Inside the cone, the digital coded signal is converted to an acoustic signal and transmitted along the steel of the drill rods to the surface. Sound signals are received by a microphone at the surface which transmits the signal to a PC via a computer interface.

Figure 2::

CPT Operation

Figure 3:

Astra CPT field log using the DI CPT Suite software. The graphs include Tip (Qc), Sleeve (Fs), Pore pressure (U2), and the probe tilt angle. The right side of the screen displays the real time values of Depth, ROP, Tip, Sleeve, Pore Pressure, and Tilt angle as well as the real time Soil Behavior Type graph.

Figure 4:

CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (RF). Log easily shows the varying soil conditions encountered when pushing CPT in Saline County, KS. Log created using CPT-Pro (post-processing software).

Figure 5:

CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (Rf). Log clearly shows the change from clay to sand in both tip pressure and pore pressure. Note the steady increase in pore pressure beginning at 36ft., indicating the probe encountered the water table. Log created using CPT-Pro (post-processing software).

Data interpretation software, called CPT-PRO, completes your CPT investigation.

- Present CPT test results

- Identify soil types using the most common CPT soil behavior classifications

- Calculate and present Geotechnical parameters

- Standard penetration test (SPT) blow count correlation

- Undrained shear strength

- Relative density

- Friction angle

- Coefficient of lateral stress

- Constrained Module

Figure 6:

CPT-PRO Data Interpretation Software: Sample Log

If you do a geotechnical boring it requires a lot of tooling, time, work, and sweat. With CPT test it's so much simpler. We completed half the borings with cone penetration testing, which cuts time and increased profit substantially. This also provided comparable data.

- Matthew Sick, Operator, Geotechnics Soil and Material Testing, Missouri

Tooling & Instrumentation

The GP Astra CPT System has several advantages for CPT users who require In-Situ measurements for their geotechnical projects:

- Developed and Built by Geoprobe Systems: This system, including hardware and software, is developed, manufactured, and supported by Geoprobe Systems.

- Accurate data collection: Each probe is constructed and calibrated to the ASTM CPT standard, D5778-20.

- Compatible with environmental subs: The Astra probes are capable of being run simultaneously with a wide variety of Geoprobe DI environmental tooling; EC, HPT, MIP, and OIP.

- Seismic and CPT in one program: The GP CPT Suite software was designed to detect if the operator is using a GP seismic section. If a seismic section is detected, the software will unlock SCPT features.

- Intuitive Acquisition Software: Easy for the operator to learn, intuitive in structure, and many features to help prevent operators from damaging the probe.

Astra CPT Probes are available in either 10 or 15 cm2 configurations, with varying load ranges depending on channel and probe size.

Figure 7:

Astra Cones

The GP Astra CPT Interface is the main hub for the CPT system, providing power to the downhole equipment, inputting stringpot information, and sending data to the laptop. Power for the CPT cone is sent downhole from the CPT Interface. The CPT data is passed through to the CPT Interface, and then to the laptop. CPT data goes directly to the laptop from the CPT Interface via Bluetooth or Serial/USB connection.

Figure 8:

Astra CPT Interface

The DI CPT Suite software is an all-in-one software package developed by Geoprobe Systems® that can run both Astra CPT and GP Seismic equipment. The CPT portion of the software graphs and displays Tip, Sleeve, Pore Pressure, Depth, Tilt angle and real time Soil Behavior Type. Users are also able to perform Dissipation tests in the CPT software. If a GP seismic section is detected, the software will unlock SCPT features.

Figure 9:

Astra CPT field log using the DI CPT Suite software. The graphs include Tip (Qc), Sleeve (Fs), Pore pressure (U2), and the probe tilt angle. The right side of the screen displays the real time values of Depth, ROP, Tip, Sleeve, Pore Pressure, and Tilt angle as well as the real time Soil Behavior Type graph.

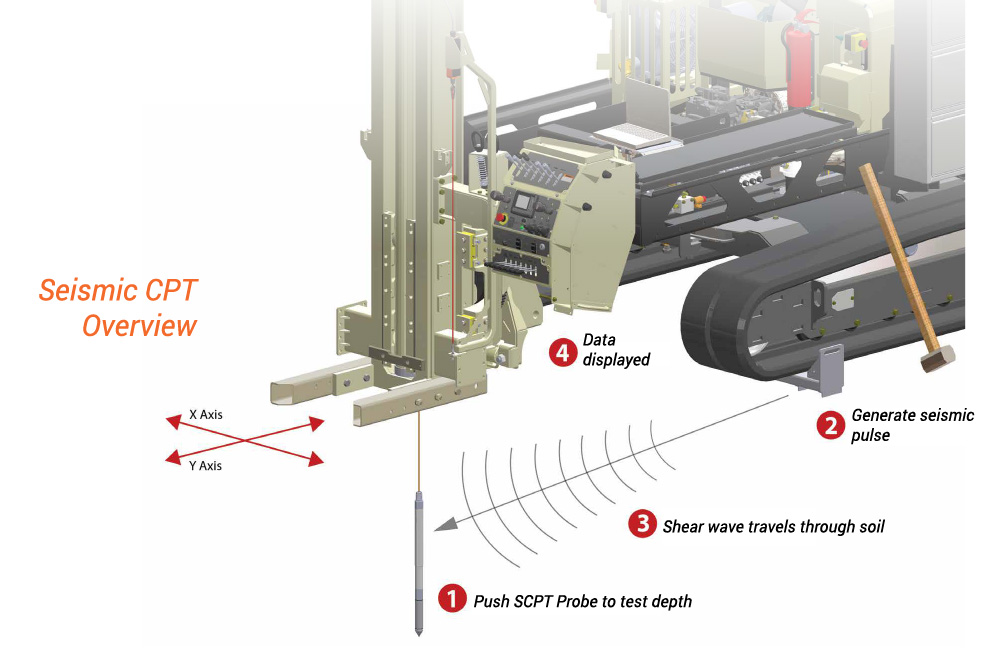

Seismic Cone Penetration Testing (SCPT) provides a rapid and cost-effective method for directly measuring shear wave velocity of soils in situ, while pushing CPT. Shear wave velocity is used as an index of liquefaction resistance since both are influenced by many of the same factors. Alternatives to using SCPT for these geotechnical analyses can require laboratory testing or less reliable, highly empirical assessments.

SCPT shear wave velocity measurements are used in these evaluations:

Liquefaction risk

Earthquake generated ground-surface movements

Foundations for vibrating equipment

Behavior of offshore structures due to wave loading

The GP Seismic Section is an add-on to our traditional CPT system. When coupling the Seismic Section with traditional CPT you will obtain details on soil types, engineering parameters, and shear wave velocity all in the same test hole.

The GP Seismic Section offers several benefits for companies and field crews. It is easy to use and cost effective as it can be added to either the Astra or NOVA CPT systems.

Geoprobe® Seismic Section Benefits include:

Rapid, cost-effective method for measuring shear wave velocities

CPT coupled with a seismic section provides details on soil types, engineering parameters, and shear wave velocity in the same test hole

Seismic sections are equipped with biaxially mounted geophones which provide a clear acquisition of the generated shear wave while reducing ambient noise.

How does the SCPT test work?

Push the seismic CPT probe to the desired test depth (shear wave velocities will be measured at multiple depths in the same push.)

Generate a seismic pulse by hitting the shear plate with a sledgehammer (the hammer hitting the plate creates a vibration that moves through the soil). Data acquisition begins as soon as the hammer hits the shear plate.

The shear wave travels from the shear plate, through the soil, and excites the geophones on the CPT seismic section as it moves past the probe's position.

The geophone data is displayed and then stored on a laptop computer. Multiple seismic traces can be generated at each depth.

Push the probe to the next measurement depth. Data is filtered and wave velocities are calculated using either the free DI Viewer software, or the 3rd party software of your choosing - this can be done in the field or at the office.

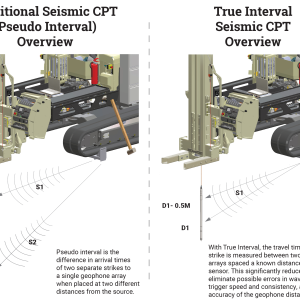

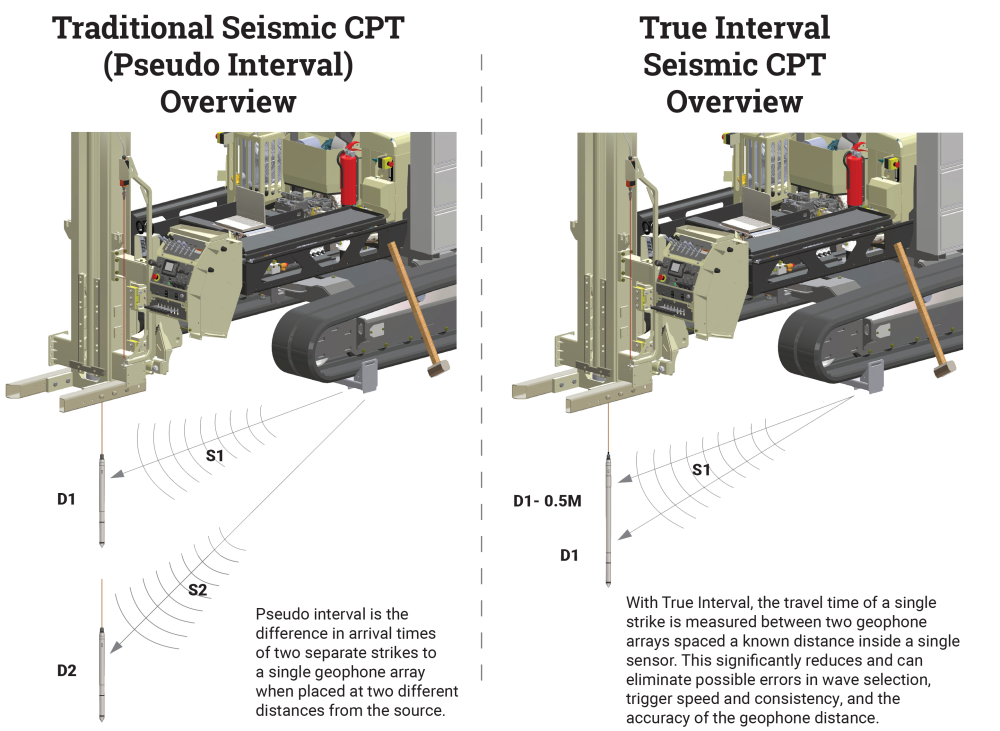

Geoprobe® True Interval Seismic Section:

Calculating shear wave velocity requires recording shear wave travel time between two depths. Traditionally, this meant taking two separate hammer strikes — one for each depth and calculating the velocity in a separate reporting program after the log is complete. With a GP TRUE INTERVAL SEISMIC SECTION, the process becomes simpler and more precise. Two sensors are positioned EXACTLY 0.5 METERS APART, allowing a SINGLE HAMMER STRIKE to be recorded at both depths. This design eliminates variability introduced by multiple strikes and improves data consistency. Since the geophones are a known distance apart, the DI CPT Suite logging software can CALCULATE THE VELOCITY IN REAL TIME. Giving the operators an instant velocity, without having to wait until they are back at the office. It also saves valuable time in the field, reduces operator fatigue, and the chance of error. The result: FASTER TESTING, CLEANER DATA, AND GREATER CONFIDENCE IN YOUR SHEAR WAVE VELOCITY CALCULATIONS.

Geoprobe® True Interval Seismic Section Benefits include:

Increased accuracy: sensors spaced exactly 0.5 m apart capture waves from the same hammer strike. Real-time software visualization confirms successful strikes in the field.

Easier in the field: sensors 0.5 meters apart rather than 1 meter increase seismic wave resolution without extra effort. By collecting data from two locations at once, see real-time velocity calculations in the logging software.

Easy addition to existing GP Seismic equipment: If you already own the GP Seismic system, the downhole True Interval section can be used with existing trunkline, and seismic interface.

Simpler set up: The same CPT Probe can be used with; CPT only, traditional seismic, or with True Interval seismic. Additionally, with the new piezo trigger on the shear plate, there’s no need to wire the plate and hammer.

Figure 10:

SCPT Test Diagram

Figure 11:

Single Seismic Wave displayed in DI CPT Suite Software during log acquisition

Figure 12:

Multiple Seismic Waves with Depth evaluated in DI Viewer Software

Figure 13:

GP Seismic Section vs GP True Interval Seismic Section; D=Depth, S=Shear Wave

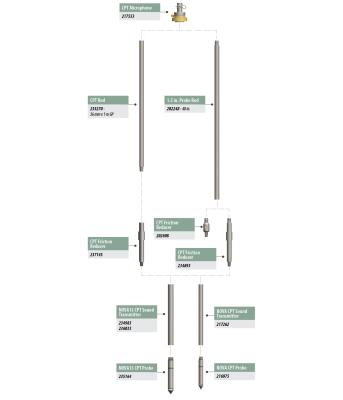

Some testing applications require that the tooling is pushed into the ground instead of hammered. To do this, the power of the machine's probe cylinder is used to advance the rod string instead of energy from the hammer. To achieve any sort of depth, a suitable reaction force must be used to balance the pushing capacity of the rig. This means that you either need a really heavy rig or you need to anchor your machine.

2060CPT:

20-ton Static Push Platform

The Geoprobe® 2060CPT is a 20 ton rated static push Cone Penetration Testing platform. The hydraulic push clamp and press advance the cone with up to 20 tons of downforce. When retracting the tool string, the 2060CPT has 30 tons of pullback. A hydraulic bottom clamp keeps rods from slipping back down hole when the push clamp is released during retrieval of the tool string. An optional 6712DT mast can be mounted on the porch end of the 2060CPT. This allows for coring, conventional soil sampling, shallow drilling for soil verification, and pre-drilling.

> Learn More

20CPT Press:

Press platform (designed for 6712DT or skid steer loaders - anchored platform)

The 20 CPT press from Geoprobe® is a flexible mast option designed specifically for performing cone penetration tests. Bracket options allow for mounting to various skid steer loaders or the Geoprobe® 6712DT. When anchored, the press has 20 tons of hydraulic downforce and 30 tons of pullback. The light weight system and small footprint allow this setup to be easily transported from location to location. This also enables the press to access sites where surface conditions will not support a larger, heavier machine.

Learn More

3230DT:

Geotechnical Combo Rig (anchored platform)

The Geoprobe® 3230DT combo rig has the ability to efficiently sample the subsurface using both direct push and rotary drilling techniques and then quickly transition to pushing CPT tooling. Anchors are installed using the CB combo head and the CPT system is automatically pushed at a rate of 2 cm / second using the same head. With the 3230DT, drillers have multiple drilling methods at their fingertips.

Learn More

7822DT:

Geotechnical Combo Rig (anchored platform)

The Geoprobe® 7822DT is designed to easily switch between multiple sampling and logging methods, including pushing CPT tooling. Anchors are installed with the augerhead to provide the reaction force needed for the up to 15 tons of push typical for this platform. Using an optional head feed control kit, automatic rate control provides cone advancement at the standard 2 cm per second. Switching between drilling tasks and pushing CPT is quick on the 7822DT and only takes a few additional components.

Learn More

3100GT:

Geotechnical Drilling Rig (anchored platform)

The 3100GT geotechnical drill rig can be setup for CPT by using a few simple anchoring components: a rod guide, anchor, and anchor bridge. Switching from geotechnical drilling to pushing CPT is a quick and simple process. Automatic head feed rate control advances the cone at a steady 2 centimeters per second specified by ASTM Standard D5778. This provides hands-free operation during advancement of each rod.

Learn More

Operators of Geoprobe® Direct Image® Environmental Tools such as Hydraulic Profiling Tool (HPT), Membrane interface Probe (MIP), or Optical Image Profiler (OIP) can add CPT to their data stream in one of these push only tool combinations. Along with the CPT geotechnical data the operator will also collect soil conductivity with electric conductivity (EC), formation permeability measurements with HPT, and UV fluorescence of non-aqueous phase fuel hydrocarbons (NAPL) with the OIP or detection of dissolved phase to NAPL levels of volatile organic compounds (VOCs) with the MIP.

Figure 18:

OIHPT sub with CPT cone lead

The OIHPT tool allows an operator to map NAPL fuels/oils by induced fluorescence from an onboard UV LED or Green laser diode with images being captured by an onboard CMOS camera. Mapping the vertical and horizontal extents of NAPL contamination along with soil EC and HPT injection pressure provides understanding of soil types, permeability and migration pathways.

> Learn More: OIP

The Membrane Interface Hydraulic Profiling Tool (MIHPT) allows an operator to map dissolved phase to NAPL levels of hydrocarbon or solvent based volatile organic compounds (VOCs). Operators around the world use MIP technology to hunt out contaminant source areas and/or delineated plume extents. The coupled EC and HPT sensors again allow for the collection of soil EC and HPT injection pressure to understand of soil types, permeability and migration pathways.

> Learn More: MIP

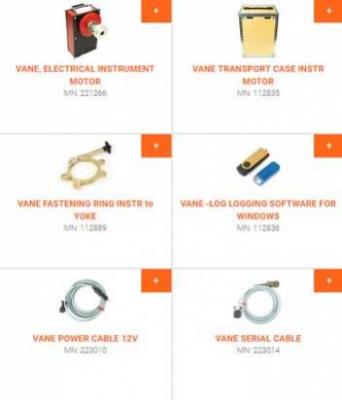

Features of NOVA CPT

- Wireless NOVA cone and data transmission technology makes logging quicker and easier!

- The only CPT probe industry-wide that provides a constant stream of real-time data while you're probing... without a cord downhole. Information collected includes soil resistance on the cone tip, resistance on the outer sides, and pore pressures generated during the test.

- The only wireless data transmission system of its kind

- The operator does not have to manage data cable as the rods are cycled in and out of the sounding hole. Rod handling is efficient, and the risk of cable damage is eliminated.

- Data transmission methods: Acoustic NOVA

- New cone design offers 18-bit resolution with improved strength and gauge measurement accuracy.

- Repeatable penetration results

- Since the rod bore is free and clear, it can be used for lubrication grouting as the rods are pushed into the ground and for retraction grouting (hole sealing) as the rods are pulled. (only available by Acoustic NOVA)

- Can be used with multiple push platforms: drill rigs, cone trucks, Geoprobe® direct push machines....

- Interpret results quickly with user-friendly CPT-PRO software for comprehensive data evaluation. Or by the free DI Viewer.

- Nova cones supplied by Geoprobe adhere to the national standards for construction (ASTM D-5778 Standard Test Method for Performing Electronic Friction Cone and Piezocone Penetration Testing of Soils, as well as ISO 22476-1-11:2004).

Videos

ID: 5533

ID: 268

ID: 1933

Resources

Click on a section below to view information.

With a true interval seismic CPT module, two sensors are positioned exactly 0.5 meters apart, allowing a single hammer strike to be recorded at both depths at the same time.

ID: 14604 | Date:

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date:

Strength of Geoprobe® manufactured ASTRA CPT cone withstands difficult geologies at an attractive price point.

ID: 14361 | Date:

Passionate about delivering exceptional geotechnical, environmental, and instrumentation exploration services, the TERRACON CONSULTANTS INC office in Savannah, Georgia, went from being without in-house drilling resources in 2021 to running three Geoprobe®

ID: 13403 | Date:

Engineers who had gained valuable geotechnical experience working for the US Army Corps of Engineers Vicksburg District and the Waterways Experiment Station in Vicksburg, Mississippi, launched BURNS COOLEY DENNIS in 1985. Now with a staff of more than 60,

ID: 13399 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.

Having offered CPT equipment for decades, Geoprobe® has come to understand how innovative and ahead of their time the first generation of CPT Cones were. These independently gauged compression cones deliver high resolution digital data, representing soil strength while being pushed into the subsurface soil. Initially equipment was available in cordless form for CPT, later adding cabled option probes to save costs. Users would have the choice to operate CPT by cordless function, or by a cable running through the rods. Seismic could also be added as a module add-on to existing CPT Probes (cones).

Today we offer the next generation of CPT by Cabled ASTRA (made by Geoprobe) and Cordless NOVA (provided by our partners at Geotech AB). These instrumented cones record with higher resolution, are more robust in construction and have improved accuracy. Both lines of cones are offered in 10cm2 and 15cm2 sizes.

ASTRA CPT was developed by Geoprobe to provide CPT users with a cost-effective option for production CPT work. Made in-house allows for improved service and firsthand expert knowledge to help solve field concerns quickly. Specific focus was made to assure there is added strength in the cone construction. It operates at the same high resolution and provides the same accuracy of other CPT cones we provide. ASTRA is run by cable, utilizing a small diameter cord like the one used in the past. This can also accept seismic into the same system by just adding a few parts. It operates and records data through Geoprobe Software made in-house, allowing for changes and updates to meet customer needs.

The Geotech AB NOVA CPT system has always been unique in the geotechnical industry and is known for its cordless data transmission system: a constant digital stream of data is sent to the surface through the sounding rods. No cable through the rods is needed in the cordless setup. NOVA CPT operates by acoustic cordless function to transmit cone signal to the surface. Cordless CPT can add simplicity to a complex setup or arrangement by not dealing with a cord to add segmented rods into the ground.

For more than 25 years, Geoprobe Systems® has partnered with Geotech AB of Sweden to be the exclusive U.S. distributor for Geotech AB Cone Penetration Testing tools for geotechnical and environmental studies. Adding to the offering is the “made by Geoprobe” ASTRA CPT allowing us to become better experts and offer customers more options to solve their field challenges. We provide service and support for all CPT equipment sold by Geoprobe, with many large-scale improvements in our test equipment and processes. We provide cone calibrations to meet ASTM standards, as well as cone and component repair services.

The cordless or corded CPT cones can be pushed with a variety of push platforms to provide continuous data, repeatable penetration results, and cost savings over traditional boring and sampling methods.

Advantages of CPT

- There are many reasons for the widespread use of the CPT test method. Probably the most important is the In-Situ measurement... it measures soil properties in the right environment; in the soil as it is, where it is.

- The real-time, on-site interpretation of logs can be used to better dial in the soil type, water table and soil parameters for engineering design – ultimately saving project cost.

- Additionally, faster production rates when compared to conventional drilling and sampling result in a more cost-effective operation.

Figure 1: Advancing CPT test with an anchored 6712 providing equal downforce of a 20 ton press

:

:

:

CPT test primary measurements include tip resistance(qc), sleeve friction(fs), and pore pressure(u). Tip resistance is a measurement of soil bearing capacity, sleeve friction is an indication of the soil cohesive strength commonly seen with clays, and pore pressure is related to the pressure generated as the cone is advanced as well as an indication to the amount of clay in the formation.

These probes are constructed of hardened alloy and tool steels. The probes consist of only a few parts; the gauged main body, tip, sleeve, and support ring. The upper end is threaded to connect to either the cable adapter or seismic section. The thread end piece at the top end of the probe is locked into place and is only intended to be removed for servicing at the factory.

A cabled CPT system uses a cable adapter or seismic section mounted behind the CPT probe to acquire in-situ Tip (Qc), Sleeve (Fs), and Pore (U2) pressure measurements and transmit the data to an operator interface at ground surface, which then displays the data on the user’s field laptop. The overall system includes the CPT probe, a method of downhole communication that couples behind the CPT cone, a simple and cost effective 1/4 in. diameter cable, the surface CPT interface, and software for acquiring cone data.

The cordless CPT does not require a cable for data transmission to the surface. Inside the cone, the digital coded signal is converted to an acoustic signal and transmitted along the steel of the drill rods to the surface. Sound signals are received by a microphone at the surface which transmits the signal to a PC via a computer interface.

Figure 2:: CPT Operation

:

:

:

Figure 3: Astra CPT field log using the DI CPT Suite software. The graphs include Tip (Qc), Sleeve (Fs), Pore pressure (U2), and the probe tilt angle. The right side of the screen displays the real time values of Depth, ROP, Tip, Sleeve, Pore Pressure, and Tilt angle as well as the real time Soil Behavior Type graph.

Figure 4: CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (RF). Log easily shows the varying soil conditions encountered when pushing CPT in Saline County, KS. Log created using CPT-Pro (post-processing software).

Figure 5: CPT test log showing Soil Classification, Tip (qc), Sleeve (fs), Pore Pressure (u2), and Friction Ratio (Rf). Log clearly shows the change from clay to sand in both tip pressure and pore pressure. Note the steady increase in pore pressure beginning at 36ft., indicating the probe encountered the water table. Log created using CPT-Pro (post-processing software).

:

Data interpretation software, called CPT-PRO, completes your CPT investigation.

- Present CPT test results

- Identify soil types using the most common CPT soil behavior classifications

- Calculate and present Geotechnical parameters

- Standard penetration test (SPT) blow count correlation

- Undrained shear strength

- Relative density

- Friction angle

- Coefficient of lateral stress

- Constrained Module

Figure 6: CPT-PRO Data Interpretation Software: Sample Log

:

:

: