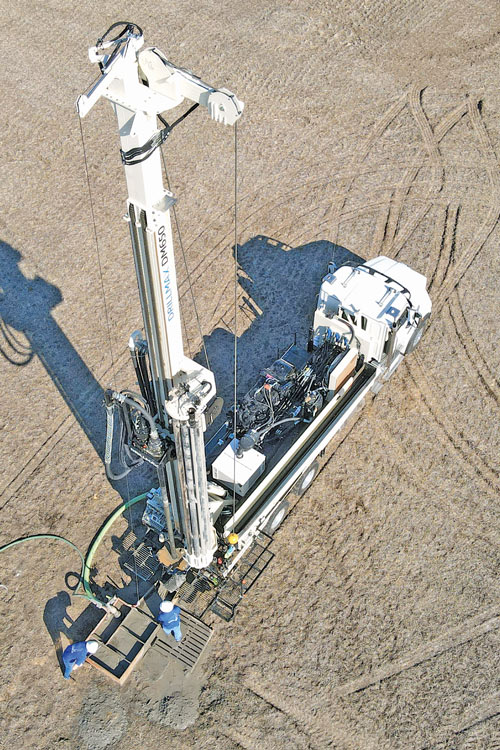

DM650 Water Well Drill Rig

Video: Geoprobe® DM650 Air Rig Overview

Large residential, light commercial, farm irrigation water well drilling and geothermal drilling

Drill deeper wells using air drilling or outfitting rig as mud drill

Drillers seeking rotary drilling options for larger, deeper wells in tough geologies choose the DRILLMAX® DM650 rotary drilling rig by Geoprobe® offering power of 28.5-foot stroke, 40,000 lb pullback, and 8,000 ft-lb torque to handle deeper wells along with weight of steel casing. Backed by our industry-leading service support, the rig offers additional advantages suited to your preferred drilling method, including:

- For air drilling or down the hole hammer set up with up to 1070/350 air compressor

- For mud drill set up with 6X8 piston pump along with a 4X3 centrifugal pump with ability to run either pump independently or supercharge piston with 4X3

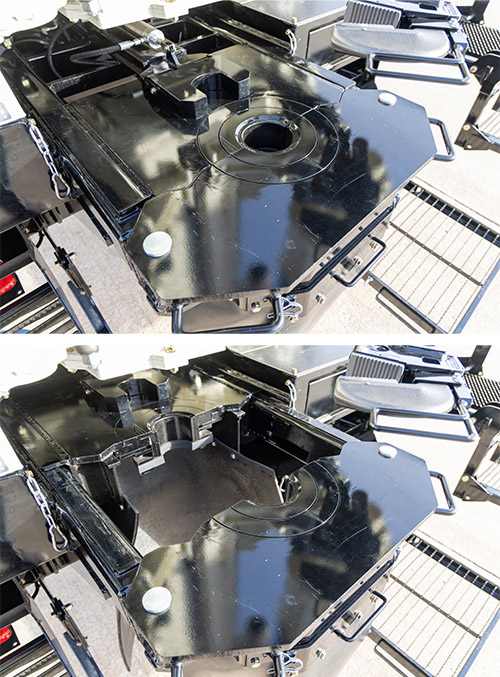

- Hydraulically retracting breakout table easily accessed from driller’s platform providing up-to 24-inch opening

Features & Options

Video: Geoprobe® Walkaround: DM650 Air Rig

DM650 can be outfitted for air drilling or mud drilling

In keeping with the DRILLMAX® by Geoprobe® reputation for simple operation and maintenance, the DM650 incorporates robust, straightforward controls, and durable components. Engineered to handle 24-inch wells up to 1,500 feet, tailor the DM650 rotary drilling rig to your specific geography and drilling preferences from a wide array of options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your air drilling rig or mud drill from the field possible with a phone call to our team of expert service technicians.

- Maximize production with your choice of rod carousel (3.5 or 4.5-inch) or single rod loader (3.5-inch) options designed to match your drilling needs.

- Simplify setting wells using the breakout table which hydraulically retracts to provide a 24-inch opening, utilizes an air fork for fast and safe tripping out, quickly switches bushing sizes, and is located outside the drill mast for plenty of room to weld the well casing.

- Tailor to your preferred drilling method with options for air drilling or mud drill. For air drilling, choose up to a 1070/350 air compressor. Mud drill options include a 6X8 piston pump and 4X3 centrifugal pump. Either pump can run independently or supercharge the duplex with the 4X3 running in front.

Possessing power to reach depth with ability to support weight of steel casing, owners of the DM650 complete large residential, light commercial, and farm irrigation water wells or geothermal drilling jobs.

With drill rig service shops in North Carolina, Pennsylvania, Florida and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth air drilling or mud drill remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your rotary drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new air drilling or mud drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new air drilling or mud drill designs.

Control Panel

DM650 Control Panel

Durable, mechanical controls neatly laid out on the robust, organized control panel on the DM650 rotary drilling rig includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

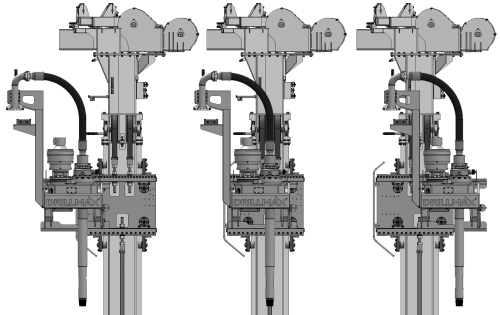

Top Head Carriage

Top head and drill mast features contribute to ability to quietly and smoothly drill deeper, bigger holes whether air drilling or outfitted as a mud drill.

Top head with 28.5-foot stroke, the carriage on the DM650 air drilling rig or mud drill uses rollers instead of slides, creating quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Drill Mast

DM650 Dual Pivoting Jib

Rigid, stout drill mast provides 40,000 lb pullback with up-to 8,000 ft-lb torque and up-to 200 rpm.

Dual pivot jib has primary and secondary winches. Primary winch swings and extends to the helper side. Secondary winch swings and extends to the driller side. Primary winch includes 17,500 or 12,000 lb options with the secondary winch offering 5,000, 2,500 or 1,800 lb options.

Mud Pump and Development Air Options

Available options for outfitting DM650 as down the hole drill or for mud drilling.

For air drilling or down the hole hammer, choose between 500/200 or 1070/350 air compressor.

Mud drill options include up to a 6X8 piston pump along with a 4X3 centrifugal pump. Either pump can run independently or supercharge the duplex with the 4X3 running in front.

Rod Carousel

DM650 Rod Carousel

Rod carousel capable of backfeeding while running drill pipe frees helper to complete other site chores. Rod carousel options available to accommodate preferred drill pipe size:

- Carry 12, 3.5-inch pipes for a total of 240 feet with ability to backfeed. The optional rod box carries an additional 18 pipes allowing you to carry a total of 600 feet on the rig with these two options.

- Carry 10, 4.5-inch pipes for a total of 200 feet with ability to backfeed. Optional rod box carries an additional 15 pipes allowing you to carry a total of 500 feet on the rig with these two options.

Top Head

Centerline Side shift

Shift top head both directions with 39 inches of total travel to work tools and casings with winches over centerline while head is positioned out of the way.

2-Speed rotary drive provides 8,000 ft-lb rotational torque and 200 rpm with 3-inch spindle thru-bore.

Table Assembly and Breakout Wrench

DM650 Table Assembly

Breakout table hydraulically retracts to provide a 24-inch opening, utilizes an air fork for fast and safe tripping out, quickly switches bushing sizes, and is located outside the drill mast for plenty of room to weld the well casing.

Truck Chassis

DM650 can be equipped as a down the hole drill or outfitted for mud drilling.

DM650 utilizes 600 HP Western Star 49X truck chassis suited for large residential, light commercial, or farm irrigation water well drilling or geothermal drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

Features & Options

Video: Geoprobe® Walkaround: DM650 Air Rig

In keeping with the DRILLMAX® by Geoprobe® reputation for simple operation and maintenance, the DM650 incorporates robust, straightforward controls, and durable components. Engineered to handle 24-inch wells up to 1,500 feet, tailor the DM650 rotary drilling rig to your specific geography and drilling preferences from a wide array of options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your air drilling rig or mud drill from the field possible with a phone call to our team of expert service technicians.

- Maximize production with your choice of rod carousel (3.5 or 4.5-inch) or single rod loader (3.5-inch) options designed to match your drilling needs.

- Simplify setting wells using the breakout table which hydraulically retracts to provide a 24-inch opening, utilizes an air fork for fast and safe tripping out, quickly switches bushing sizes, and is located outside the drill mast for plenty of room to weld the well casing.

- Tailor to your preferred drilling method with options for air drilling or mud drill. For air drilling, choose up to a 1070/350 air compressor. Mud drill options include a 6X8 piston pump and 4X3 centrifugal pump. Either pump can run independently or supercharge the duplex with the 4X3 running in front.

Possessing power to reach depth with ability to support weight of steel casing, owners of the DM650 complete large residential, light commercial, and farm irrigation water wells or geothermal drilling jobs.

With drill rig service shops in North Carolina, Pennsylvania, Florida and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth air drilling or mud drill remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your rotary drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new air drilling or mud drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new air drilling or mud drill designs.

Durable, mechanical controls neatly laid out on the robust, organized control panel on the DM650 rotary drilling rig includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

Top head with 28.5-foot stroke, the carriage on the DM650 air drilling rig or mud drill uses rollers instead of slides, creating quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Rigid, stout drill mast provides 40,000 lb pullback with up-to 8,000 ft-lb torque and up-to 200 rpm.

Dual pivot jib has primary and secondary winches. Primary winch swings and extends to the helper side. Secondary winch swings and extends to the driller side. Primary winch includes 17,500 or 12,000 lb options with the secondary winch offering 5,000, 2,500 or 1,800 lb options.

For air drilling or down the hole hammer, choose between 500/200 or 1070/350 air compressor.

Mud drill options include up to a 6X8 piston pump along with a 4X3 centrifugal pump. Either pump can run independently or supercharge the duplex with the 4X3 running in front.

Rod carousel capable of backfeeding while running drill pipe frees helper to complete other site chores. Rod carousel options available to accommodate preferred drill pipe size:

- Carry 12, 3.5-inch pipes for a total of 240 feet with ability to backfeed. The optional rod box carries an additional 18 pipes allowing you to carry a total of 600 feet on the rig with these two options.

- Carry 10, 4.5-inch pipes for a total of 200 feet with ability to backfeed. Optional rod box carries an additional 15 pipes allowing you to carry a total of 500 feet on the rig with these two options.

Shift top head both directions with 39 inches of total travel to work tools and casings with winches over centerline while head is positioned out of the way.

2-Speed rotary drive provides 8,000 ft-lb rotational torque and 200 rpm with 3-inch spindle thru-bore.

Breakout table hydraulically retracts to provide a 24-inch opening, utilizes an air fork for fast and safe tripping out, quickly switches bushing sizes, and is located outside the drill mast for plenty of room to weld the well casing.

DM650 utilizes 600 HP Western Star 49X truck chassis suited for large residential, light commercial, or farm irrigation water well drilling or geothermal drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

Man, I love the DM650. It looks like it’s built well. I appreciate the design of the new mud pump and the amount of power it has. It’s a very nice, heavy-duty machine.

- Mark Kelly, Owner, Emerald Coast, Alabama

Videos

DM Water Well Rig Series Overview

ID: 14052

Geoprobe® Walkaround: DM650 Air Rig

ID: 14045

ID: 13356

ID: 13269

Specs

Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

| Width (in) | 102 | Width (mm) | 2,591 | |

| Length (transport) (in) | 488 | Length (transport) (mm) | 12,395 | |

| Length (transport) (ft) | 40.7 | Length (transport) (m) | 12.4 | |

| Length (deployed) (in) | 450.2 | Length (deployed) (mm) | 11,435 | |

| Length (deployed) (ft) | 37.5 | Length (deployed) (m) | 11.4 | |

| Height (transport) (in) | 162 | Height (transport) (mm) | 4,115 | |

| Height (transport) (ft) | 13.5 | Height (transport) (m) | 4.11 | |

| Height (deployed) (in) | 545 | Height(mm) | 13843 | |

| Height (deployed) (ft) | 45.4 | Height (deployed) (m) | 13.84 | |

| Height Extended (deployed) (in) | 580.8 | Height Extended (deployed) (mm) | 14752.32 | |

| Height Extended (deployed) (ft) | 48.4 | Height Extended (deployed) (m) | 14.75 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 48 | Front outrigger travel (mm) | 122 | |

| Rear outrigger travel (in) | 36 | Rear outrigger travel (mm) | 91 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 342 | Head Travel (mm) | 8,687 | |

| Head Travel (ft) | 28.5 | Head Travel (m) | 8.69 | |

| Head Crowd Force (lbs) | 21,000 | Head Crowd Force (kN) | 93 | |

| Head Pull Force (lbs) | 40,000 | Head Pull Force (kN) | 178 | |

| Head Side shift (in) | 40 | Head Side shift (mm) | 1016 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Western Star 49X | Truck | Western Star 49X | |

| Engine | Detroit DD16 | Engine | Detroit DD16 | |

| Engine Rated Power (hp) | 600 | Engine Rated Power (kW) | 447 | |

| Transmission Options | 18-speed manual | Transmission Options | 18-speed manual | |

| Fuel Capacity (gal) | 200 | Fuel Capacity (L) | 757 | |

| Rotary Drive Options | Rotary Drive Options | |||

| 2-Speed Rotary Drive | DMR8 | 2-Speed Rotary Drive | DMR8 | |

| Rotation Torque(ft-lb) (LSHT) | 8000 | Rotation Torque (N-m) (LSHT) | 10,847 | |

| Rotation Speed (rpm) (HSLT) | 200 | Rotation Speed (rpm) (HSLT) | 200 | |

| Spindle thru bore (in) | 3 | Spindle thru bore (mm) | 76 | |

| Spindle Output | Flange | Spindle Output | Flange | |

| Primary Winch (2-speed) | Primary Winch (2-speed) | |||

| Option 1 | ||||

| line pull (lbf) | 17,500 | line pull (kN) | 77.84 | |

| line speed (fpm) (High speed) | 200 | line speed (m/min) | 61 | |

| cable length (ft) | 150 | cable length (m) | 46 | |

| Option 2 | ||||

| line pull (lbf) | 12,000 | line pull (kN) | 53.38 | |

| line speed (fpm) (High speed) | 166 | line speed (m/min) | 51 | |

| cable length (ft) | 135 | cable length (m) | 41 | |

| Secondary Winch | Secondary Winch | |||

| Option 1 | ||||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 240 | line speed (m/min) | 73 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Option 2 | ||||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 | |

| line speed (fpm) | 125 | line speed (m/min) | 38 | |

| cable length (ft) | 280 | cable length (m) | 85 | |

| Option 3 | ||||

| line pull (lbf) | 5000 | line pull (kN) | 22.24 | |

| line speed (fpm) | 130 | line speed (m/min) | 40 | |

| cable length (ft) | 150 | cable length (m) | 46 | |

| Breakout | Breakout | |||

| Table Opening (in) | 24 | Table Opening (mm) | 610 | |

| Single Clamp | Single Clamp | |||

| Breakout torque (ft-lb) | 16,600 | Breakout torque (N-m) | 22,507 |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

| Width (in) | 102 | Width (mm) | 2,591 | |

| Length (transport) (in) | 488 | Length (transport) (mm) | 12,395 | |

| Length (transport) (ft) | 40.7 | Length (transport) (m) | 12.4 | |

| Length (deployed) (in) | 450.2 | Length (deployed) (mm) | 11,435 | |

| Length (deployed) (ft) | 37.5 | Length (deployed) (m) | 11.4 | |

| Height (transport) (in) | 162 | Height (transport) (mm) | 4,115 | |

| Height (transport) (ft) | 13.5 | Height (transport) (m) | 4.11 | |

| Height (deployed) (in) | 545 | Height(mm) | 13843 | |

| Height (deployed) (ft) | 45.4 | Height (deployed) (m) | 13.84 | |

| Height Extended (deployed) (in) | 580.8 | Height Extended (deployed) (mm) | 14752.32 | |

| Height Extended (deployed) (ft) | 48.4 | Height Extended (deployed) (m) | 14.75 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 48 | Front outrigger travel (mm) | 122 | |

| Rear outrigger travel (in) | 36 | Rear outrigger travel (mm) | 91 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 342 | Head Travel (mm) | 8,687 | |

| Head Travel (ft) | 28.5 | Head Travel (m) | 8.69 | |

| Head Crowd Force (lbs) | 21,000 | Head Crowd Force (kN) | 93 | |

| Head Pull Force (lbs) | 40,000 | Head Pull Force (kN) | 178 | |

| Head Side shift (in) | 40 | Head Side shift (mm) | 1016 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Western Star 49X | Truck | Western Star 49X | |

| Engine | Detroit DD16 | Engine | Detroit DD16 | |

| Engine Rated Power (hp) | 600 | Engine Rated Power (kW) | 447 | |

| Transmission Options | 18-speed manual | Transmission Options | 18-speed manual | |

| Fuel Capacity (gal) | 200 | Fuel Capacity (L) | 757 | |

| Rotary Drive Options | Rotary Drive Options | |||

| 2-Speed Rotary Drive | DMR8 | 2-Speed Rotary Drive | DMR8 | |

| Rotation Torque(ft-lb) (LSHT) | 8000 | Rotation Torque (N-m) (LSHT) | 10,847 | |

| Rotation Speed (rpm) (HSLT) | 200 | Rotation Speed (rpm) (HSLT) | 200 | |

| Spindle thru bore (in) | 3 | Spindle thru bore (mm) | 76 | |

| Spindle Output | Flange | Spindle Output | Flange | |

| Primary Winch (2-speed) | Primary Winch (2-speed) | |||

| Option 1 | ||||

| line pull (lbf) | 17,500 | line pull (kN) | 77.84 | |

| line speed (fpm) (High speed) | 200 | line speed (m/min) | 61 | |

| cable length (ft) | 150 | cable length (m) | 46 | |

| Option 2 | ||||

| line pull (lbf) | 12,000 | line pull (kN) | 53.38 | |

| line speed (fpm) (High speed) | 166 | line speed (m/min) | 51 | |

| cable length (ft) | 135 | cable length (m) | 41 | |

| Secondary Winch | Secondary Winch | |||

| Option 1 | ||||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 240 | line speed (m/min) | 73 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Option 2 | ||||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 | |

| line speed (fpm) | 125 | line speed (m/min) | 38 | |

| cable length (ft) | 280 | cable length (m) | 85 | |

| Option 3 | ||||

| line pull (lbf) | 5000 | line pull (kN) | 22.24 | |

| line speed (fpm) | 130 | line speed (m/min) | 40 | |

| cable length (ft) | 150 | cable length (m) | 46 | |

| Breakout | Breakout | |||

| Table Opening (in) | 24 | Table Opening (mm) | 610 | |

| Single Clamp | Single Clamp | |||

| Breakout torque (ft-lb) | 16,600 | Breakout torque (N-m) | 22,507 |

Resources

Click on a section below to view information.

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

Faster drilling. Smarter pipe handling. One-stop support.

ID: 14543 | Date:

DM650 Air provides time-saving features like backloading carousel and top head side shift.

ID: 14345 | Date:

Geoprobe® Engineers spend time building in the shop and testing in the field to create quality machines for customers.

ID: 14080 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.