Slide Maintenance

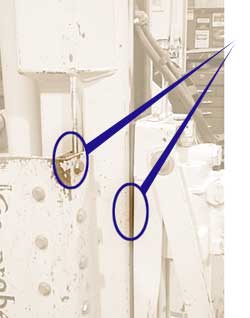

Nylon slides on your Geoprobe®® machine are located between the foot and the tilt bracket, and between the hammer and the front of the foot.

Q: Why is it important to keep the slides on your direct push machine tightened and to replace them when they're worn?

A: Longer probe life and better machine performance.

Geoprobe Systems® uses slides at key wear points on the unit to protect the machine during operation. Slides allow the working parts of the machine to move adjacent to each other without wear and without the need for lubrication (i.e., grease, oil). The slides also provide stability for the foot and the probe when they are properly tightened and not worn. When the bolts that hold the slides in place become loose, or the slides themselves become worn, you’ll notice additional movement in the foot and the probe cylinder. This puts your machine in jeopardy! As a result, the tilt bracket, foot, and probe cylinder, as well as other components of your machine, may become damaged or prematurely wear out. So, don’t slight your slides. Keep an eye on them and tighten/replace the slides when necessary. Service Bulletin No. 19808 is now available to help with this process. Or, you can schedule a makeover session for your Geoprobe® machine with the Resource Center guys and they’ll include a slide checkup when they service your machine.

Q: Why is it important to keep the slides on your direct push machine tightened and to replace them when they're worn?

A: Longer probe life and better machine performance.

Geoprobe Systems® uses slides at key wear points on the unit to protect the machine during operation. Slides allow the working parts of the machine to move adjacent to each other without wear and without the need for lubrication (i.e., grease, oil). The slides also provide stability for the foot and the probe when they are properly tightened and not worn. When the bolts that hold the slides in place become loose, or the slides themselves become worn, you’ll notice additional movement in the foot and the probe cylinder. This puts your machine in jeopardy! As a result, the tilt bracket, foot, and probe cylinder, as well as other components of your machine, may become damaged or prematurely wear out. So, don’t slight your slides. Keep an eye on them and tighten/replace the slides when necessary. Service Bulletin No. 19808 is now available to help with this process. Or, you can schedule a makeover session for your Geoprobe® machine with the Resource Center guys and they’ll include a slide checkup when they service your machine.

Service Knowledgebase Index

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Service Locations

Kansas Service Center - Salina, KS

1835 Wall Street • Salina, Kansas 67401

785-825-1842Just one mile west of I-135 and an hour and half north of Wichita or two and half hours west of Kansas City, the drill rig service team keeps customers in the field through telephone service support or in shop repairs.

Southeast Service Center - Ocala, FL

5801 SW 6th Place • Ocala, Florida 34474

352-854-1566Just one mile west of I-75 and an hour northwest of Orlando, drillers have come to rely on the drill rig service team with double-digit years of hands-on experience servicing any rig for helpful answers or intensive rig fixes.

East Coast Service Center - Oxford, PA

468 Limestone Rd • Oxford, PA 19363

610-467-1750Just 30 minutes off of I-95, an hour west of Philadelphia, and two hours southwest of Newark, New Jersey. Rely on our team for refurbishments, repairs, and aftermarket upgrades for any rig.

North Carolina Service Center - Hickory, NC

2515 US Highway 70 SW • Hickory, NC 28602

828-998-0977Just 5 minutes off I-40 and an hour northwest of Charlotte, the drill rig service team provides support ranging from routine maintenance to intensive repairs for any rig.