2060CPT Rig

Video: Geoprobe® 2060CPT Introduction

Climate Control for CPT

Drillers seeking to rely on static weight for their CPT machine choose the 2060CPT. Completing cone penetration testing (CPT testing) from the comfort of the climate-controlled cabin on the CPT machine, clients can observe the large visual display projecting real-time data as testing is performed. The 142 HP engine/hydraulic systems provide the CPT machine with excellent climbing and turning ability in rugged/unlevel terrain or steep grades. Low ground pressure of 7-psi minimizes terrain disturbance while the swinging control panel allows for operation from either side of the low-profile CPT press. Additional advantages of the CPT machine include:

- 20-tons of downforce and 30-tons of pull with weight evenly distributed over the entire platform for efficient CPT testing

- Option to add a 6712DT mast outside the CPT machine for coring, conventional soil sampling, shallow drilling for soil verification and pre-drilling

- Large side door makes for easy loading and unloading of rods and equipment

Owners seeking to serve geotechnical and environmental industries find the 2060CPT well suited for utilizing Direct Image® tooling to complete their environmental investigations from the comfort of the CPT machine.

Features & Options

Video: Geoprobe® 2060CPT Overview

Owners seeking to expand their CPT testing service area choose the 2060CPT realizing customers appreciate the comfort of the climate-controlled cabin on the CPT machine. However, its versatility to serve various industries with Direct Image® tooling and available options to perform pre-drilling and other conventional soil sampling results in expanded CPT machine utilization.

- COMFORT: user-friendly control panel allows operation from either side of the CPT machine. Climate-controlled cabin expands calendar for CPT testing. Large side door allows for open air environment when desired.

- CONVENIENCE: large engine bay doors ease engine maintenance. Option for additional mast provides capability to conduct other types of coring with the same CPT machine. Large side door allows for easy loading of rods and equipment. Digital display affords real-time viewing of CPT testing data.

- CONTROL: four hydraulic outriggers provide machine leveling. Engine/hydraulic systems provide excellent climbing and turning in tough terrains or on steep grades. Low ground pressure limits terrain disturbance. Static weight distributed evenly over the entire platform with 20 tons downforce and 30 tons pull makes CPT testing efficient.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your CPT machine is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new CPT machine? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

20 Tons Downforce / 30 Tons of Pull

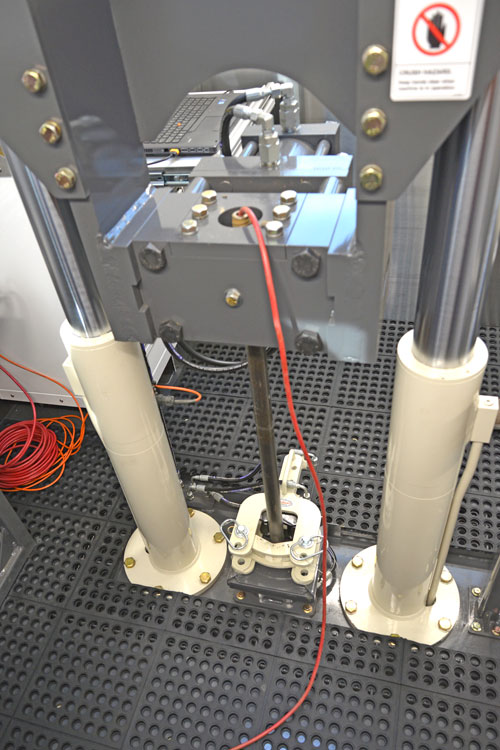

Push the cone with up to 20 tons downforce with the hydraulic push clamp and press on the 2060CPT machine.

The rig features 20 tons of downforce and 30 tons of pull. With a push through center of gravity, the weight is evenly distributed over the entire platform. The weight of the entire cabin crawler is centered at the press clamp so that the entire mass of the crawler is applied to the tool string being advanced.

The hydraulic push clamp and press can push the cone with up to 20 tons of downforce. The amount of force can be adjusted on the control panel. A hydraulic bottom clamp is used to keep rods from slipping back down hole when the push clamp is released. When retracting the tool string, the 2060CPT has 30 tons of pull.

Robust Track System

Climb and turn with ease using the robust track system on the 2060CPT.

The robust track system of the 142-horsepower 2060CPT allows for CPT testing in most terrains. Its proven drive-train and chassis provide excellent climbing and turning ability. With a ground pressure of 7 psi, it causes minimal disturbance to the terrain with minimal ground pressure at the tracks. The rig is tracked to the testing location with either a wireless or tethered remote.

Climate-controlled Cabin with Large Side Door

Easily load and unload rods and equipment on the 2060CPT.

The climate-controlled cabin has a large side door that allows for easy loading and unloading of rods and equipment.

Shear Wave Generators (optional)

Measure shear wave with optional shear wave generators available for the 2060CPT.

Optional shear wave generators are used to generate a shear wave impact for sensing measurement by the Seismic Cone Penetrometer. They provide a sharp, swift hammer strike, producing a clean energy wave through the soil for the cone to read.

6712DT Mast (optional)

Use your CPT machine for coring, soil sampling, soil verification drilling, and pre-drilling when you add the optional 6712DT mast on the porch side.

An optional 6712DT mast can be mounted on to the porch side of the 2060CPT. This allows for coring, conventional soil sampling, shallow drilling for soil verification, and pre-drilling. In many cases, it may be required to create a hole opening for CPT by clearing concrete or debris. The 6712DT mast opens up these options on one rig. It is located in-line with the CPT press inside the cabin. The crawler can easily be tracked over the drilled hole when the time comes to perform the CPT test.

Control Panel

Position comfortably to see CPT cone and readouts with the user-friendly control panel on swing arm in the 2060CPT.

The compact, user friendly control panel allows for all functions and hydraulic controls to be controlled from one location. It features a swing arm, allowing for control from either side of the press.

Under-mounted Camera

Monitor position of the cone using internal screen display of undercarriage-mounted camera on the 2060CPT.

A camera is mounted to the undercarriage for precise location of the machine over the hole. Internal monitors allow for viewing the camera as well as logging information.

Four Hydraulic Outriggers for Leveling Machine

Fine tune leveling of your CPT machine using the outriggers on the 2060CPT.

During setup, four hydraulic outriggers are used for leveling the machine.

Large Engine Bay Doors

Maintenance made simple with the large engine bay doors on the 2060CPT.

Accessing the engine for service is easy with the large engine bay doors.

Additional Features

Keep your field needs within reach thanks to storage and work benches in the 2060CPT.

Additional features and options of the 2060CPT include:

- Geoprobe® standard rail system for easy mounting of accessories

- Interior work benches and high-quality slide drawers and cabinet storage

- Optional external side toolboxes

- External auxiliary hydraulic connections to power accessories

- 120-volt power via hydraulic driven generator

- A wash port for decontamination in the drop tube below the press

- Large engine bay doors for easy service

- Remote monitoring of unit health

Features & Options

Video: Geoprobe® 2060CPT Overview

Owners seeking to expand their CPT testing service area choose the 2060CPT realizing customers appreciate the comfort of the climate-controlled cabin on the CPT machine. However, its versatility to serve various industries with Direct Image® tooling and available options to perform pre-drilling and other conventional soil sampling results in expanded CPT machine utilization.

- COMFORT: user-friendly control panel allows operation from either side of the CPT machine. Climate-controlled cabin expands calendar for CPT testing. Large side door allows for open air environment when desired.

- CONVENIENCE: large engine bay doors ease engine maintenance. Option for additional mast provides capability to conduct other types of coring with the same CPT machine. Large side door allows for easy loading of rods and equipment. Digital display affords real-time viewing of CPT testing data.

- CONTROL: four hydraulic outriggers provide machine leveling. Engine/hydraulic systems provide excellent climbing and turning in tough terrains or on steep grades. Low ground pressure limits terrain disturbance. Static weight distributed evenly over the entire platform with 20 tons downforce and 30 tons pull makes CPT testing efficient.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your CPT machine is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new CPT machine? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

The rig features 20 tons of downforce and 30 tons of pull. With a push through center of gravity, the weight is evenly distributed over the entire platform. The weight of the entire cabin crawler is centered at the press clamp so that the entire mass of the crawler is applied to the tool string being advanced.

The hydraulic push clamp and press can push the cone with up to 20 tons of downforce. The amount of force can be adjusted on the control panel. A hydraulic bottom clamp is used to keep rods from slipping back down hole when the push clamp is released. When retracting the tool string, the 2060CPT has 30 tons of pull.

The robust track system of the 142-horsepower 2060CPT allows for CPT testing in most terrains. Its proven drive-train and chassis provide excellent climbing and turning ability. With a ground pressure of 7 psi, it causes minimal disturbance to the terrain with minimal ground pressure at the tracks. The rig is tracked to the testing location with either a wireless or tethered remote.

The climate-controlled cabin has a large side door that allows for easy loading and unloading of rods and equipment.

Optional shear wave generators are used to generate a shear wave impact for sensing measurement by the Seismic Cone Penetrometer. They provide a sharp, swift hammer strike, producing a clean energy wave through the soil for the cone to read.

An optional 6712DT mast can be mounted on to the porch side of the 2060CPT. This allows for coring, conventional soil sampling, shallow drilling for soil verification, and pre-drilling. In many cases, it may be required to create a hole opening for CPT by clearing concrete or debris. The 6712DT mast opens up these options on one rig. It is located in-line with the CPT press inside the cabin. The crawler can easily be tracked over the drilled hole when the time comes to perform the CPT test.

The compact, user friendly control panel allows for all functions and hydraulic controls to be controlled from one location. It features a swing arm, allowing for control from either side of the press.

A camera is mounted to the undercarriage for precise location of the machine over the hole. Internal monitors allow for viewing the camera as well as logging information.

During setup, four hydraulic outriggers are used for leveling the machine.

Accessing the engine for service is easy with the large engine bay doors.

Additional features and options of the 2060CPT include:

- Geoprobe® standard rail system for easy mounting of accessories

- Interior work benches and high-quality slide drawers and cabinet storage

- Optional external side toolboxes

- External auxiliary hydraulic connections to power accessories

- 120-volt power via hydraulic driven generator

- A wash port for decontamination in the drop tube below the press

- Large engine bay doors for easy service

- Remote monitoring of unit health

“In the Midwest, there are a number of months that are not best for investigative work. We’ve got the best working space available for clients to come and enjoy it while we’re performing their investigation.”

- Dale Elliott, President, MATECO, Michigan

Tooling & Accessories

The NOVA CPT test cone introduces higher resolution, more robust construction and improved accuracy. NOVA CPT delivers improved durability and sensitivity in an instrumented cone. The Geotech AB NOVA CPT system has always been unique in the geotechnical industry and is known for its cordless data transmission system: a constant digital stream of data is sent to the surface through the sounding rods. No cable through the rods is needed in the cordless setup. Cable CPT has always been an option, but now with Cable NOVA we can offer an entry-level cost-effective approach. For more than 20 years, Geoprobe Systems® has teamed up with Geotech AB of Sweden to be the exclusive U.S. distributor for Geotech AB Cone Penetration Testing tools for geotechnical and environmental studies. We also provide the service and support, offering repair and calibration services. The cordless or corded NOVA CPT test cones can be used from a variety of push platforms to provide continuous data, repeatable penetration results, and cost savings over traditional boring and sampling methods. NOVA Cones adhere to the national standards for construction (ASTM D-5778 Standard Test Method for Performing Electronic Friction Cone and Piezocone Penetration Testing of Soils, as well as ISO 22476-1-11:2004).

Videos

ID: 1896

Geoprobe® 2060CPT Introduction

ID: 1895

Specs

Specifications are subject to change without notice.

| Weight (standard machine) | 40,000 lb (18,150 kg) |

| Length | 245 in (6,223 mm) - 287 in (7,290 mm) With Optional Drill Mast |

| Width | 99 in (2,819 mm) |

| Height | 128 in (3,252 mm) |

| Cabin size | 144 in L x 96 in W (3,658 mm L x 2,438 mm W) |

| Ground Pressure | 7 psi (49 kPa) |

| Press Down Force (20 Ton) | 40,000 lb (178 kN) |

| Press Retraction Force | 60,000 lb (267 kN) |

| Press Cylinder Stroke | 39.4 in (1,000 mm) |

| Press Cylinder Speed CPT | 2 cm/s (.787 in/s) Rapid: 63 ft/min (19 m/min) |

| Press Cylinder Speed Up | 27 ft/min (8.2 m/min) Regen: 37 ft/min (11.3 m/min) |

| Fuel Cap | 50 gal |

| Engine | CAT, 4-Cylinder Turbocharged |

| Engine HP | 142 hp (106 kW) |

| Hydraulic Oil Reservoir | 65 gal (246 L) |

| Hydraulic Flow (max | 100 gpm (379 Lpm) |

| Hydraulic System Pressure (max) | 4000 psi (276 bar) |

| Generator capacity | 6,000 Watt |

| Inverter and Battery Backup | 600 watt |

| Auxiliary Hydraulic Outlet Flow | 0-20 gpm (75 Lpm) |

| Auxiliary Hydraulic Outlet Pressure | 3,000 psi (207 bar) |

| Ground Speed | 1.9 mph (3.0 kph) |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Weight (standard machine) | 40,000 lb (18,150 kg) |

| Length | 245 in (6,223 mm) - 287 in (7,290 mm) With Optional Drill Mast |

| Width | 99 in (2,819 mm) |

| Height | 128 in (3,252 mm) |

| Cabin size | 144 in L x 96 in W (3,658 mm L x 2,438 mm W) |

| Ground Pressure | 7 psi (49 kPa) |

| Press Down Force (20 Ton) | 40,000 lb (178 kN) |

| Press Retraction Force | 60,000 lb (267 kN) |

| Press Cylinder Stroke | 39.4 in (1,000 mm) |

| Press Cylinder Speed CPT | 2 cm/s (.787 in/s) Rapid: 63 ft/min (19 m/min) |

| Press Cylinder Speed Up | 27 ft/min (8.2 m/min) Regen: 37 ft/min (11.3 m/min) |

| Fuel Cap | 50 gal |

| Engine | CAT, 4-Cylinder Turbocharged |

| Engine HP | 142 hp (106 kW) |

| Hydraulic Oil Reservoir | 65 gal (246 L) |

| Hydraulic Flow (max | 100 gpm (379 Lpm) |

| Hydraulic System Pressure (max) | 4000 psi (276 bar) |

| Generator capacity | 6,000 Watt |

| Inverter and Battery Backup | 600 watt |

| Auxiliary Hydraulic Outlet Flow | 0-20 gpm (75 Lpm) |

| Auxiliary Hydraulic Outlet Pressure | 3,000 psi (207 bar) |

| Ground Speed | 1.9 mph (3.0 kph) |

Resources

Click on a section below to view information.

With more than 25 years of experience, Geoprobe® has the technical team and equipment to support your CPT endeavors. “Cory and Troy have made efforts to be at our disposal to ask questions and their response time is exceptional,” said Derek Wolfe, engine

ID: 13401 | Date:

Given their service area in the north-central United States, the climate-controlled cabin of the Geoprobe® 2060CPT Crawler provided an advantage MATECO thought their customers would appreciate...

ID: 5117 | Date:

The Geoprobe® 2060CPT is a 20-ton-rated, static push Cone Penetration Testing platform that allows users to maximize their efforts...

ID: 2113 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.