DM450 Water Well Drill Rig

Video: Geoprobe® Walkaround: DM450 Water Well Rig

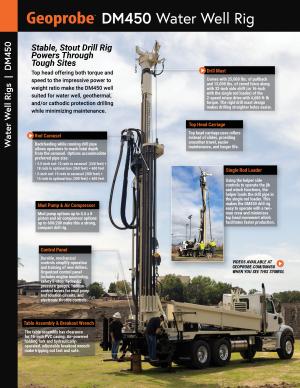

Stable, stout drill rig powers through tough sites

Drillers seeking versatile water well drill rigs with power and reliability to tackle water well drilling, geothermal drilling, and cathodic protection drilling choose DM450 water well drill rigs for speed and ease combined with reduced downtime. Additional advantages of the water well drill rigs for sale include:

- upgraded head-feed system with adjustable rollers, rotary head side shift, and increased pullback

- enhanced ease created by durable, mechanical controls and secure routing of hydraulic hoses

- increased production capability provided by dual winches and rod loader with helper side controls OR rod carousel with ability to back feed

Customers claim the DM450 water well drill rigs are “quieter, faster, and easier to operate.”

Features & Options

Video: Geoprobe® DM450 Water Well Rig Overview

DM450 for deep water well drilling, geothermal, and cathodic protection now comes on an automatic truck chassis to further simplify mobilization.

Mud system, top head travel speed, and rotation speed and power combine to quickly conquer clay or cobbles to increase production and profit. Engineered to handle 4-inch to 12-inch wells up to 1,000 feet, tailor the DM450 to your specific geography and drilling preferences from a wide array of drill rig options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your rig from the field possible with a phone call to our team of expert service technicians. Owners describe their DM450 as “stable” and “stout,” praising its simple operation for making it easy to train new operators.

- Increase production drilling larger wells with the compact machine easily maneuvering on job sites. The DM450 provides ample head feed speed - activated with a fast feed circuit - to flush the cuttings out of holes drilled in sand or clay, providing a clean hole to drop well casing or cathodic protection anodes. The rig also features the top head rotation speed needed to handle tricky formations – such as sticky clay.

- Expand access choosing from multiple mud pump and air compressor options to configure the rig for specific geographic areas. Some options, such as sandline winch or pipe spinner systems, can be added to minimize equipment on geothermal job sites.

- Ease operation with engineered design and modern construction, maximizing power to quickly and easily complete jobs while streamlining maintenance and troubleshooting. The control panel with its durable, mechanical controls, simplifies operation. The table assembly – with an opening to handle up to 16-inch casing – is positioned further back from the rig, making it easier to handle tooling and set casing.

- Improved serviceability with third generation DMR6 top head.

Armed with the fast head feed speed, many DM450 owners successfully complete deep water well drilling, geothermal drilling, or cathodic protection drilling with the same machine.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your deep water well drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new water well drill rigs? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new water well drill rigs design for our DRILLMAX® deep water well drilling rigs by Geoprobe®. Our goal is to make your job faster, safer, and easier. Partner with us and we'll work to decrease your water well drill rigs downtime while increasing your family time.

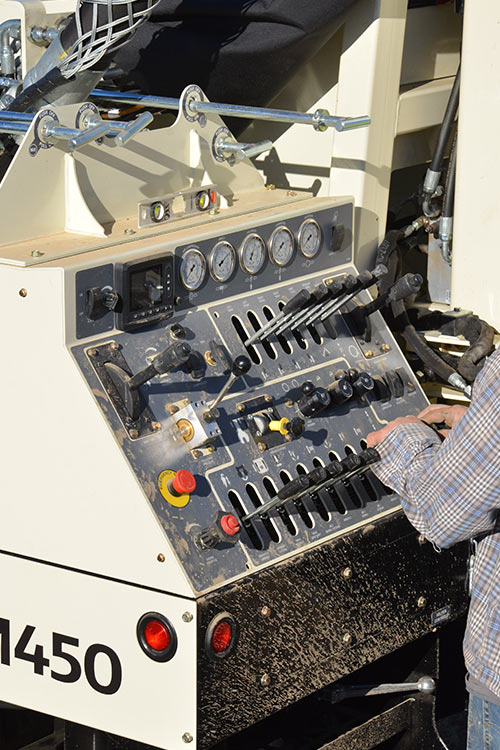

Control Panel

Manual hydraulic controls on DM450 deep water well drilling rig provide power, precision, and reduced maintenance.

The durable, mechanical controls neatly laid out on the robust, organized control panel includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

Top Head Carriage

Rollers on DM450 deep water well drilling rig top head carriage provide smoother transitions and easier adjustments.

The top head carriage on the DM450 drill truck uses rollers instead of slides, creating quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Drill Mast

Sturdy drillmast on DM450 makes for straighter holes

Video: DRILLMAX® DM450 - Jib and Winch System

Totally redesigned drillmast on the DM450 drill rig with 25,000-lbs of pullback, 15,000-lbs of crowd force along with 16-inch side shift of the 2-speed rotary drive with 4,600 ft-lb torque. The rigid drill mast design makes drilling straighter holes easier.

The 2-speed main winch motor on the DM450 provides full pull power when tripping out or with flip of a switch provides full speed, making travel time twice as fast. For job sites where support trucks won't fit on helper side, second jib swings and extends — in the other direction toward the driller's side —to pick up and place smaller objects.

- 2-speed winch motor on main jib for full pull power or full speed with simple flip of switch.

- main 12,000-lbf line pull jib swings and extends over helper's side.

- second 1,800-lbf jib swings and extends over driller's side to cut time setting casing.

Mud Pump and Development Air Options

Assorted mud pump options available on DM450 deep water well drilling rig to suit multiple applications and geographic conditions.

Mud pump options up to 5 ½ x 8 piston or series 4X3 centrifugal pumps and air compressor options up to 600/200 make this a strong compact unit.

600/200 Air Compressor

The higher cfm output boosts performance for multiple drilling tasks. In air rotary drilling, it clears cuttings faster, keeping progress steady and reducing stuck rods. When driving steel casing with a hammer, the extra airflow improves efficiency, and lets casings advance smoothly even in tough formations. Maintenance of the 600/200 air compressor is also easier.

Rod Loader and Helper Side Controls

Effective rod box and single rod loader makes for fast tripping in and out of the hole with the DM450.

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single rod loader. This makes the DM450 easy to operate with a two-man crew.

Table Assembly

Wide driller's platform around DM450 table assembly increases comfort on the job.

Video: DRILLMAX® DM450 - Table

The DM450 drill truck table assembly has clearance for 16-inch PVC casing. Easy access to table opening from control panel simplifies setting variety of casing sizes.

- remove bushings to set up-to 10-inch casing.

- remove center bushings and use control panel to retract table when setting 12-inch casing.

- remove bushings and use control panel to retract table then remove pin and swing open gate to make room for 16-inch casing.

Breakout Wrench

Hydraulic breakout wrench makes job easier on driller.

Air-powered holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe with the DM450 drill rig. The grease fittings on the fork help maintain mobility in freezing conditions.

Truck Chassis

Powerful automatic truck chassis for fast and easy mobilization.

Available on a 450 HP Western Star 47X truck chassis to further simplify mobilization, the lightweight, compact drill rig is suited for large residential water wells, commercial geothermal, and cathodic protection drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

INCREASED HORSEPOWER

Easily mobilize on tough terrain or up hills thanks to 450 HP Western Star 47X chassis with automatic transmission. Increased horsepower means more options, including series 4X3 centrifugal pumps and water transfer pump.

6x6 All Wheel Drive

6x6 AWD on the DM450 provides simple, reliable power for enhanced traction and maneuverability when traveling on difficult job sites.

To navigate sandy or muddy job sites, Geoprobe® DM450 now offers a proven hydraulic drive assist front axle — the same 6X6 technology used in fire trucks, dump trucks, cranes, and utility digger devices.

- Low center of gravity for stability on uneven terrain

- Front axle engages at the push of a button — no park or neutral needed

- Tighter Turning Radius

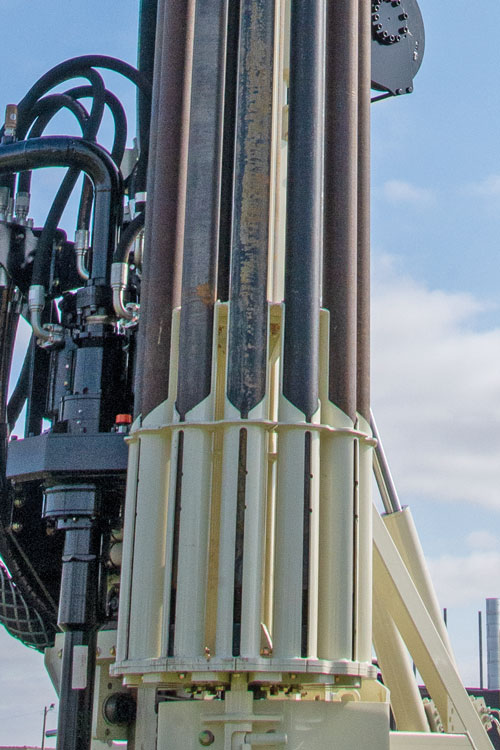

Rod Carousel and Rod Box

Grooves along carousel and arrow marker provide visual indicator when aligning rotary head over rods.

Video: DRILLMAX® DM450 - Rod Carousel

Create opportunity to task helper with other site chores or run a one-man job when you choose rod carousel option capable of backfeeding while running pipe.

- simple, durable hydraulic fork at top of carousel operated from control panel holds drill pipe in position.

- pod for each drill pipe contains a cushion spring prohibiting pipe from slamming into pod, protecting drill pipe and creating a quieter job site.

- mechanical alignment of top head with rods using indicator arrow and grooves on base eliminates need for electrical sensor that could malfunction.

Rod carousel options available to accommodate preferred drill pipe size:

- Carry 15, 3-inch pipes for a total of 300 feet with ability to backfeed carousel as running pipe.

- Carry 12, 3.5-inch pipes for a total of 240 feet with ability to backfeed carousel as running pipe.

- Carry 10, 4.5-inch pipes for a total of 200 feet with ability to backfeed carousel as running pipe.

On-board Mud Cleaning System

Factory-mounted Mudslayer® 250 drilling mud cleaning system

Video: DRILLMAX® DM450 - Mud Cleaning System

Factory-mounted Mudslayer® 250 drilling mud cleaning system uses separate hydraulic circuit eliminating competition among functions, easily connects to pump for quick set up. Addition of the deck-mounted drilling mud cleaning system allows access closer to homes without hauling a mud pan behind the rig, eliminates shoveling out mud pans making job easier on drillers, and creates simpler job site cleanup.

On-board Grout Mixer

Deck-mounted grouter mixes and pumps simultaneously.

Runs off of rig hydraulics, saving fuel compared to running an extra engine.

Pipe Spinner System

Pipe spinner system takes hands off drill pipe for faster, easier, safer field work.

Bi-directional, hands-free pipe spinner system takes hands off drill pipe to quickly make and break joints with less wear on driller.

- switch on control panel dictates which direction wheels spin.

- single lever control engages both clamp and spinning function.

- innovative segmented rollers made of staggered, stacked plates with teeth to grab pipe increase performance, longevity, and ease of service.

- threaded fitting adjusts bumpers to optimize pipe spinner grip performance based on size of drill pipe used.

DMR6 Top Head

DMR6 Top Head on DM450

Next Generation DMR6 Top Head on DM450

Engineers focused energy into improving the manufacturability, enhancing durability in the field, and simplifying serviceability of the DMR6 top head featured on the NEW Western Star chassis DM450.

Billet-Machined Gearbox provides improved strength, durability, and accuracy. The redesigned gearbox simplifies assembly as well as service in the field.

Higher Load Capacity Spindle and Pinion Shaft Bearings contribute to longer life in rough field conditions.

Splined Spindle significantly improves torque carrying capacity and longevity over keyways.

Redesigned Top Swivel

- easy packing seal adjustment can be completed in seconds with minimal tools

- improved seals and design prevent water ingression into the gearbox

Features & Options

Video: Geoprobe® DM450 Water Well Rig Overview

Mud system, top head travel speed, and rotation speed and power combine to quickly conquer clay or cobbles to increase production and profit. Engineered to handle 4-inch to 12-inch wells up to 1,000 feet, tailor the DM450 to your specific geography and drilling preferences from a wide array of drill rig options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your rig from the field possible with a phone call to our team of expert service technicians. Owners describe their DM450 as “stable” and “stout,” praising its simple operation for making it easy to train new operators.

- Increase production drilling larger wells with the compact machine easily maneuvering on job sites. The DM450 provides ample head feed speed - activated with a fast feed circuit - to flush the cuttings out of holes drilled in sand or clay, providing a clean hole to drop well casing or cathodic protection anodes. The rig also features the top head rotation speed needed to handle tricky formations – such as sticky clay.

- Expand access choosing from multiple mud pump and air compressor options to configure the rig for specific geographic areas. Some options, such as sandline winch or pipe spinner systems, can be added to minimize equipment on geothermal job sites.

- Ease operation with engineered design and modern construction, maximizing power to quickly and easily complete jobs while streamlining maintenance and troubleshooting. The control panel with its durable, mechanical controls, simplifies operation. The table assembly – with an opening to handle up to 16-inch casing – is positioned further back from the rig, making it easier to handle tooling and set casing.

- Improved serviceability with third generation DMR6 top head.

Armed with the fast head feed speed, many DM450 owners successfully complete deep water well drilling, geothermal drilling, or cathodic protection drilling with the same machine.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your deep water well drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new water well drill rigs? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new water well drill rigs design for our DRILLMAX® deep water well drilling rigs by Geoprobe®. Our goal is to make your job faster, safer, and easier. Partner with us and we'll work to decrease your water well drill rigs downtime while increasing your family time.

The durable, mechanical controls neatly laid out on the robust, organized control panel includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

The top head carriage on the DM450 drill truck uses rollers instead of slides, creating quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Totally redesigned drillmast on the DM450 drill rig with 25,000-lbs of pullback, 15,000-lbs of crowd force along with 16-inch side shift of the 2-speed rotary drive with 4,600 ft-lb torque. The rigid drill mast design makes drilling straighter holes easier.

The 2-speed main winch motor on the DM450 provides full pull power when tripping out or with flip of a switch provides full speed, making travel time twice as fast. For job sites where support trucks won't fit on helper side, second jib swings and extends — in the other direction toward the driller's side —to pick up and place smaller objects.

- 2-speed winch motor on main jib for full pull power or full speed with simple flip of switch.

- main 12,000-lbf line pull jib swings and extends over helper's side.

- second 1,800-lbf jib swings and extends over driller's side to cut time setting casing.

Video: DRILLMAX® DM450 - Jib and Winch System

Mud pump options up to 5 ½ x 8 piston or series 4X3 centrifugal pumps and air compressor options up to 600/200 make this a strong compact unit.

600/200 Air Compressor

The higher cfm output boosts performance for multiple drilling tasks. In air rotary drilling, it clears cuttings faster, keeping progress steady and reducing stuck rods. When driving steel casing with a hammer, the extra airflow improves efficiency, and lets casings advance smoothly even in tough formations. Maintenance of the 600/200 air compressor is also easier.

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single rod loader. This makes the DM450 easy to operate with a two-man crew.

The DM450 drill truck table assembly has clearance for 16-inch PVC casing. Easy access to table opening from control panel simplifies setting variety of casing sizes.

- remove bushings to set up-to 10-inch casing.

- remove center bushings and use control panel to retract table when setting 12-inch casing.

- remove bushings and use control panel to retract table then remove pin and swing open gate to make room for 16-inch casing.

Video: DRILLMAX® DM450 - Table

Air-powered holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe with the DM450 drill rig. The grease fittings on the fork help maintain mobility in freezing conditions.

Available on a 450 HP Western Star 47X truck chassis to further simplify mobilization, the lightweight, compact drill rig is suited for large residential water wells, commercial geothermal, and cathodic protection drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

INCREASED HORSEPOWER

Easily mobilize on tough terrain or up hills thanks to 450 HP Western Star 47X chassis with automatic transmission. Increased horsepower means more options, including series 4X3 centrifugal pumps and water transfer pump.

To navigate sandy or muddy job sites, Geoprobe® DM450 now offers a proven hydraulic drive assist front axle — the same 6X6 technology used in fire trucks, dump trucks, cranes, and utility digger devices.

- Low center of gravity for stability on uneven terrain

- Front axle engages at the push of a button — no park or neutral needed

- Tighter Turning Radius

Create opportunity to task helper with other site chores or run a one-man job when you choose rod carousel option capable of backfeeding while running pipe.

- simple, durable hydraulic fork at top of carousel operated from control panel holds drill pipe in position.

- pod for each drill pipe contains a cushion spring prohibiting pipe from slamming into pod, protecting drill pipe and creating a quieter job site.

- mechanical alignment of top head with rods using indicator arrow and grooves on base eliminates need for electrical sensor that could malfunction.

Rod carousel options available to accommodate preferred drill pipe size:

- Carry 15, 3-inch pipes for a total of 300 feet with ability to backfeed carousel as running pipe.

- Carry 12, 3.5-inch pipes for a total of 240 feet with ability to backfeed carousel as running pipe.

- Carry 10, 4.5-inch pipes for a total of 200 feet with ability to backfeed carousel as running pipe.

Video: DRILLMAX® DM450 - Rod Carousel

Factory-mounted Mudslayer® 250 drilling mud cleaning system uses separate hydraulic circuit eliminating competition among functions, easily connects to pump for quick set up. Addition of the deck-mounted drilling mud cleaning system allows access closer to homes without hauling a mud pan behind the rig, eliminates shoveling out mud pans making job easier on drillers, and creates simpler job site cleanup.

Video: DRILLMAX® DM450 - Mud Cleaning System

Runs off of rig hydraulics, saving fuel compared to running an extra engine.

Bi-directional, hands-free pipe spinner system takes hands off drill pipe to quickly make and break joints with less wear on driller.

- switch on control panel dictates which direction wheels spin.

- single lever control engages both clamp and spinning function.

- innovative segmented rollers made of staggered, stacked plates with teeth to grab pipe increase performance, longevity, and ease of service.

- threaded fitting adjusts bumpers to optimize pipe spinner grip performance based on size of drill pipe used.

Next Generation DMR6 Top Head on DM450

Engineers focused energy into improving the manufacturability, enhancing durability in the field, and simplifying serviceability of the DMR6 top head featured on the NEW Western Star chassis DM450.

Billet-Machined Gearbox provides improved strength, durability, and accuracy. The redesigned gearbox simplifies assembly as well as service in the field.

Higher Load Capacity Spindle and Pinion Shaft Bearings contribute to longer life in rough field conditions.

Splined Spindle significantly improves torque carrying capacity and longevity over keyways.

Redesigned Top Swivel

- easy packing seal adjustment can be completed in seconds with minimal tools

- improved seals and design prevent water ingression into the gearbox

“The rigid drill mast design drills straighter holes.The redesigned rod spinner increases efficiency tripping out of the hole.”

- Skyler Wilson, Operations Manager, PanTerra Energy, Colorado

Applications

Videos

Specs

Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

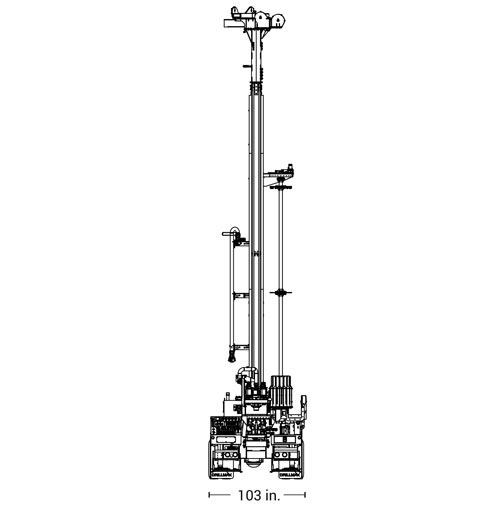

| Width (in) | 102 | Width (mm) | 2,591 | |

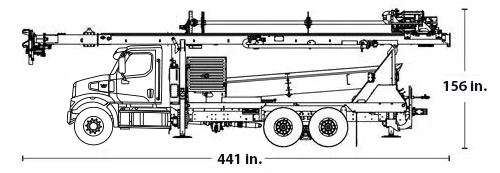

| Length (transport) (in) | 441 | Length (transport) (mm) | 11,208 | |

| Length (transport) (ft) | 36.8 | Length (transport) (m) | 11.21 | |

| Length (deployed) (in) | 396 | Length (deployed) (mm) | 10,058 | |

| Length (deployed) (ft) | 33.0 | Length (deployed) (m) | 10.1 | |

| Height (transport) (in) | 156 | Height (transport) (mm) | 3,962 | |

| Height (transport) (ft) | 13 | Height (transport) (m) | 3.96 | |

| Height (deployed) (in) | 493 | Height (mm) | 12510 | |

| Height (deployed) (ft) | 41.0 | Height (deployed) (m) | 12.51 | |

| Unit Weight (As typically equipped) (lbs) | 48,500 | Unit Weight (As typically equipped) (kg) | 21,999 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 36 | Front outrigger travel (mm) | 91 | |

| Rear outrigger travel (in) | 36 | Rear outrigger travel (mm) | 91 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 312 | Head Travel (mm) | 7,925 | |

| Head Travel (ft) | 26.0 | Head Travel (m) | 7.92 | |

| Head Crowd Force (lbs) | 15,000 | Head Crowd Force (kN) | 67 | |

| Head Pull Force (lbs) | 25,000 | Head Pull Force (kN) | 111 | |

| Head Side shift (in) (w/o carousel) | 16 | Head Side shift (mm) | 406 | |

| Head Side shift (in) (w/ carousel) | 32 | Head Side shift (mm) | 813 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Western Star® 47X | Truck | Western Star® 47X | |

| Engine | Detroit® DD13® | Engine | Detroit® DD13® | |

| Engine Rated Power (hp) | 470 | Engine Rated Power (kW) | 350 | |

| Transmission Options | Allison 4500 RDS Automatic | Transmission Options | Allison 4500 RDS Automatic | |

| Fuel Capacity (gal) | 190 | Fuel Capacity (L) | 719 | |

| Rotary Drive Options | Rotary Drive Options | |||

| 2-Speed Rotary Drive | DMR6 | 2-Speed Rotary Drive | DMR6 | |

| Rotation Torque (ft-lb) (LSHT) | 4600 | Rotation Torque (N-m) (LSHT) | 6,237 | |

| Rotation Speed (rpm) (HSLT) | 330 | Rotation Speed (rpm) (HSLT) | 330 | |

| Spindle Output | API 3.5" IF | Spindle Output | API 3.5" IF | |

| Primary Winch (2-speed) | Primary Winch (2-speed) | |||

| line pull (lbf) | 12,000 | line pull (kN) | 53.38 | |

| line speed (fpm) (High speed) | 166 | line speed (m/min) | 51 | |

| cable length (ft) | 135 | cable length (m) | 41 | |

| Secondary Winch | Secondary Winch | |||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 240 | line speed (m/min) | 73 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Breakout | Breakout | |||

| Table Opening (in) | 16 | Table Opening (mm) | 406 | |

| Single Clamp | 6 | Single Clamp | ||

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8,135 |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

| Width (in) | 102 | Width (mm) | 2,591 | |

| Length (transport) (in) | 441 | Length (transport) (mm) | 11,208 | |

| Length (transport) (ft) | 36.8 | Length (transport) (m) | 11.21 | |

| Length (deployed) (in) | 396 | Length (deployed) (mm) | 10,058 | |

| Length (deployed) (ft) | 33.0 | Length (deployed) (m) | 10.1 | |

| Height (transport) (in) | 156 | Height (transport) (mm) | 3,962 | |

| Height (transport) (ft) | 13 | Height (transport) (m) | 3.96 | |

| Height (deployed) (in) | 493 | Height (mm) | 12510 | |

| Height (deployed) (ft) | 41.0 | Height (deployed) (m) | 12.51 | |

| Unit Weight (As typically equipped) (lbs) | 48,500 | Unit Weight (As typically equipped) (kg) | 21,999 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 36 | Front outrigger travel (mm) | 91 | |

| Rear outrigger travel (in) | 36 | Rear outrigger travel (mm) | 91 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 312 | Head Travel (mm) | 7,925 | |

| Head Travel (ft) | 26.0 | Head Travel (m) | 7.92 | |

| Head Crowd Force (lbs) | 15,000 | Head Crowd Force (kN) | 67 | |

| Head Pull Force (lbs) | 25,000 | Head Pull Force (kN) | 111 | |

| Head Side shift (in) (w/o carousel) | 16 | Head Side shift (mm) | 406 | |

| Head Side shift (in) (w/ carousel) | 32 | Head Side shift (mm) | 813 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Western Star® 47X | Truck | Western Star® 47X | |

| Engine | Detroit® DD13® | Engine | Detroit® DD13® | |

| Engine Rated Power (hp) | 470 | Engine Rated Power (kW) | 350 | |

| Transmission Options | Allison 4500 RDS Automatic | Transmission Options | Allison 4500 RDS Automatic | |

| Fuel Capacity (gal) | 190 | Fuel Capacity (L) | 719 | |

| Rotary Drive Options | Rotary Drive Options | |||

| 2-Speed Rotary Drive | DMR6 | 2-Speed Rotary Drive | DMR6 | |

| Rotation Torque (ft-lb) (LSHT) | 4600 | Rotation Torque (N-m) (LSHT) | 6,237 | |

| Rotation Speed (rpm) (HSLT) | 330 | Rotation Speed (rpm) (HSLT) | 330 | |

| Spindle Output | API 3.5" IF | Spindle Output | API 3.5" IF | |

| Primary Winch (2-speed) | Primary Winch (2-speed) | |||

| line pull (lbf) | 12,000 | line pull (kN) | 53.38 | |

| line speed (fpm) (High speed) | 166 | line speed (m/min) | 51 | |

| cable length (ft) | 135 | cable length (m) | 41 | |

| Secondary Winch | Secondary Winch | |||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 240 | line speed (m/min) | 73 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Breakout | Breakout | |||

| Table Opening (in) | 16 | Table Opening (mm) | 406 | |

| Single Clamp | 6 | Single Clamp | ||

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8,135 |

Operator Side - Unfolded

Operator Side - Folded

Unfolded

Resources

Click on a section below to view information.

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

Compact footprint of DM450 slips into wooded lots with ease, possessing power to reach depth and pull rods.

ID: 14588 | Date:

The 6x6 All-Wheel Drive on the Geoprobe® DM450 improves the ability to navigate sandy or muddy job sites.

ID: 14587 | Date:

Features like backloading carousel on DM450 provide confidence to tackle large geothermal.

ID: 14586 | Date:

DM450 equipped with twin centrifugal pumps offers impressive performance for diversified drilling sites.

ID: 14343 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.