3145GT Geotechnical Drill Rig

Video:

Efficiency and Performance to Punch Out Power and Pipe Line Projects

Drillers seeking to quickly traverse long stretches of tough terrain encountered on pipe line, power line or wind farm projects choose the 3145GT geotechnical drill rig, combining the efficiency and simplicity of 31 series drill mast with speed and comfort of crawler carrier.

- Power and versatility: effectively compete in multiple revenue streams – HSA, SPT, CPT, DPT, rock coring, mud rotary, air rotary, and drive and wash

- Centerline head side shift: aligns all head functions and winches over the bore hole without moving the drill mast for efficient drilling.

- Simple controls with hands-free rotation, head feed, and auto drop hammer: makes work nearly effortless and creates a gentle learning curve for the seasoned driller as well as the new hire

- Crawler carrier: results in an agile drill rig capable of traveling from hole-to-hole at a top speed of 6 mph

- Enclosed operator cabin: offers creature comforts of heat, AC, and radio

Features & Options

Video: Geoprobe® 3145GT Walkaround

Long, off-road treks are simplified with efficiency and performance of 3145GT.

Enhancements on the 3145GT include:

- Enhanced off-road capability: easily run on rugged off-road terrain with crawler chassis

- Increased tool storage: simplify housekeeping especially on long treks

- Taller standard winch: effectively pull 20-foot tool string with attached split spoon above the breakout

Options include:

- high torque 6-speed rotary head

- third winch

- pivoting winch mast for lower transport height

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your geotechnical drill is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new geotechnical drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Geotech Head

All head and winch functions align over bore hole using centerline head side shift.

Effectively compete in multiple revenue streams – HSA, SPT, CPT, DPT, rock coring, mud rotary, air rotary, and drive and wash - with the centerline head side shift aligning all head functions and winches over the bore hole. Features GH63 percussion hammer 4-speed rotary head with 4,000 ft-lb, DH104 hands-free automatic drop hammer, CPT push/pull assembly, and a rod grip pull system along 28-inch side shift to speed up drilling and minimize time driller spends in danger zone.

Higher-torque Rotary Head

The 6-speed GR6.5 rotary head has 6,800 ft-lbs of torque with top end speed of 720 rpm.

While customers are proving the rock coring capabilities of the 4-speed rotary head on the 31 series rigs, the 6-speed GR6.5 rotary head option offers 70 percent more torque. The GR6.5 has 7,000 ft-lbs of torque, which is 3,000 ft-lbs more than the GR4.1 on a typical 7822DT, without sacrificing top-end speed (720 rpm). An additional intermediate-speed range further enhances wet and air rotary capabilities.

Hands-free Auto Drop Hammer

Hands-free automatic drop hammer keeps drillers out of harms way longer.

The hands-free automatic drop hammer reduces strain when driving SPT samples. With 170-lb, 300-lb, or 340-lb options, advance borings for SPT testing by augering, driven casing and sampling, or wash boring.

Telescoping Winch Mast/Drill Mast Oscillation

Effectively pull 20-foot tool string with attached split spoon above the breakout using standard winch mast.

The winch mast telescopes into place, allowing for flexible height options based on work environment. This also adds a layer of safety during setup when working near overhead power lines or other obstacles.

Taller telescoping winch mast specifically designed for geotech work with heavier winch options, 105-inches head travel, and 36,000-lbf push and 48,000-lbf pull at the head-feed cylinder means greater pull back – ideal for drive and wash – and head travel. Effectively pull 20-foot tool string with attached split spoon above the breakout

Align the probe cylinder and tool string on a straight – or angled – path to the subsurface while the machine remains stable with the built-in oscillation, standard on all machines.

Drill mast features extend, swing, mast dump, oscillation, and fold. Mast dump provides 36.5 inches of vertical travel to allow room for a mud pan. Optional outriggers available.

Winch Options

Optional third winch suited for wireline coring.

A dual winch option is typically configured with a 6,800-lbf winch for the more difficult pulling and an 1,800-lbf. with quick-change hook. When ready to switch from pulling to coring, simply swap out the swivel hook for the overshot clevis installed on your overshot and continue working. It’s quick, simple, and can all be done by hand.

Additional winch options include 2,500-lbf and 1,100-lbf.

Also available is a third winch with 1,100 lbs of line pull, well suited to trip additional tooling out of the hole. Equipped with the Geoprobe® exclusive quick change hook, operators can switch over to wireline coring in seconds.

Pivoting Winch Mast

Simple, mechanical actuator with pivoting winch mast option lowers transportation height by 15 inches.

The pivoting winch mast option is designed for customers lowers the transportation height by 15 inches using a simple, mechanical ratcheting actuator.

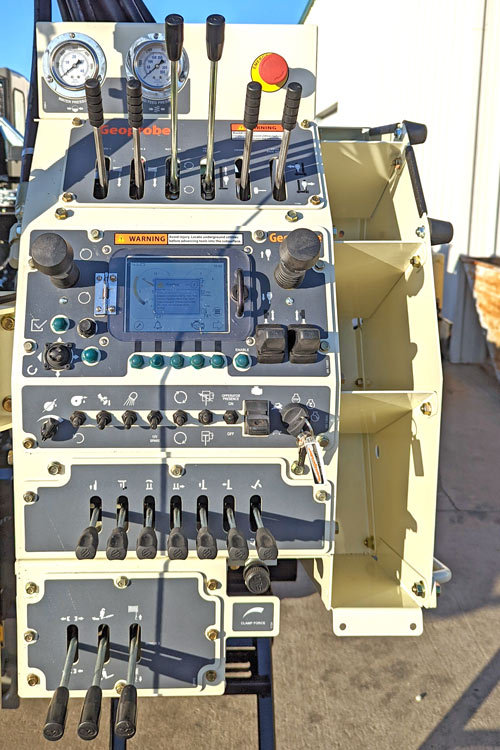

Control Panel

Manual controls provide tactile feel; electric controls add safe, hands-free operation.

You'll find all functions at your fingertips in a well-organized, compact control panel. The systems display provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Hands-free rotary and head feed controls on the 3145GT reduce strain on driller when completing applications like mud rotary. CPT feed rate and hydraulic limit functions are standard.

7-inch Clamp Breakout

Swing-out breakout can be under the hammer or rotary drive, or away from the 3145GT.

The 7-inch single breakout firmly grips casing with a clamp force of up to 21,000 pounds of force. The breakout can be positioned either under the hammer or the rotary drive, as well as swung away from the machine.

An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

Tooling Transportation/Storage

3145GT geotechnical drill rig comes well equipped with tool storage.

Simplify housekeeping especially on long treks with multiple tooling storage rack options and tool boxes as well as convenient storage along the control panel and breakout.

Crawler Carrier

Efficiently travel between bore holes in comfort of enclosed cabin.

Crawler carrier creates an agile drill rig capable of traveling from hole-to-hole at a top speed of 6 mph. Enjoy creature comforts of heat, AC, and radio in the enclosed cabin.

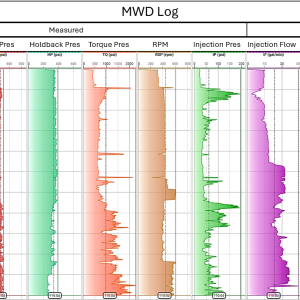

Measurement While Drilling (MWD)

MWD

MWD (Measurement While Drilling) is a method of collecting digital data from the drill rig to log parameters pertaining to drilling operation. These methods are common in other parts of the world where it has been standard to log or measure drilling parameters in the oil, gas, and mining industries.

Starting in 2024, Geoprobe® 31 series geotechnical drill rigs are MWD capable. The option can be added at any time to include an MWD kit allowing drilling parameters to be recorded

- Common parameters for MWD are crowd force, torque, penetration rate, mud pump pressure, mud flow rate, holdback pressure, head rotation speed and hole depth.

- Follows ISO 22476-15 International Standard for MWD.

- All sensors utilized are common Geoprobe® components with proven experience and reliability.

- MWD sensors are easily integrated into existing rig electronics to maximize usefulness of sensor data being currently collected.

- Calibrated outputs are delivered to the data logger of your choice via J1939 CAN Bus network on the drill, simplifying the rig’s wiring.

Features & Options

Video: Geoprobe® 3145GT Walkaround

Enhancements on the 3145GT include:

- Enhanced off-road capability: easily run on rugged off-road terrain with crawler chassis

- Increased tool storage: simplify housekeeping especially on long treks

- Taller standard winch: effectively pull 20-foot tool string with attached split spoon above the breakout

Options include:

- high torque 6-speed rotary head

- third winch

- pivoting winch mast for lower transport height

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your geotechnical drill is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new geotechnical drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Effectively compete in multiple revenue streams – HSA, SPT, CPT, DPT, rock coring, mud rotary, air rotary, and drive and wash - with the centerline head side shift aligning all head functions and winches over the bore hole. Features GH63 percussion hammer 4-speed rotary head with 4,000 ft-lb, DH104 hands-free automatic drop hammer, CPT push/pull assembly, and a rod grip pull system along 28-inch side shift to speed up drilling and minimize time driller spends in danger zone.

While customers are proving the rock coring capabilities of the 4-speed rotary head on the 31 series rigs, the 6-speed GR6.5 rotary head option offers 70 percent more torque. The GR6.5 has 7,000 ft-lbs of torque, which is 3,000 ft-lbs more than the GR4.1 on a typical 7822DT, without sacrificing top-end speed (720 rpm). An additional intermediate-speed range further enhances wet and air rotary capabilities.

The hands-free automatic drop hammer reduces strain when driving SPT samples. With 170-lb, 300-lb, or 340-lb options, advance borings for SPT testing by augering, driven casing and sampling, or wash boring.

The winch mast telescopes into place, allowing for flexible height options based on work environment. This also adds a layer of safety during setup when working near overhead power lines or other obstacles.

Taller telescoping winch mast specifically designed for geotech work with heavier winch options, 105-inches head travel, and 36,000-lbf push and 48,000-lbf pull at the head-feed cylinder means greater pull back – ideal for drive and wash – and head travel. Effectively pull 20-foot tool string with attached split spoon above the breakout

Align the probe cylinder and tool string on a straight – or angled – path to the subsurface while the machine remains stable with the built-in oscillation, standard on all machines.

Drill mast features extend, swing, mast dump, oscillation, and fold. Mast dump provides 36.5 inches of vertical travel to allow room for a mud pan. Optional outriggers available.

A dual winch option is typically configured with a 6,800-lbf winch for the more difficult pulling and an 1,800-lbf. with quick-change hook. When ready to switch from pulling to coring, simply swap out the swivel hook for the overshot clevis installed on your overshot and continue working. It’s quick, simple, and can all be done by hand.

Additional winch options include 2,500-lbf and 1,100-lbf.

Also available is a third winch with 1,100 lbs of line pull, well suited to trip additional tooling out of the hole. Equipped with the Geoprobe® exclusive quick change hook, operators can switch over to wireline coring in seconds.

The pivoting winch mast option is designed for customers lowers the transportation height by 15 inches using a simple, mechanical ratcheting actuator.

You'll find all functions at your fingertips in a well-organized, compact control panel. The systems display provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Hands-free rotary and head feed controls on the 3145GT reduce strain on driller when completing applications like mud rotary. CPT feed rate and hydraulic limit functions are standard.

The 7-inch single breakout firmly grips casing with a clamp force of up to 21,000 pounds of force. The breakout can be positioned either under the hammer or the rotary drive, as well as swung away from the machine.

An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

Simplify housekeeping especially on long treks with multiple tooling storage rack options and tool boxes as well as convenient storage along the control panel and breakout.

Crawler carrier creates an agile drill rig capable of traveling from hole-to-hole at a top speed of 6 mph. Enjoy creature comforts of heat, AC, and radio in the enclosed cabin.

MWD (Measurement While Drilling) is a method of collecting digital data from the drill rig to log parameters pertaining to drilling operation. These methods are common in other parts of the world where it has been standard to log or measure drilling parameters in the oil, gas, and mining industries.

Starting in 2024, Geoprobe® 31 series geotechnical drill rigs are MWD capable. The option can be added at any time to include an MWD kit allowing drilling parameters to be recorded

- Common parameters for MWD are crowd force, torque, penetration rate, mud pump pressure, mud flow rate, holdback pressure, head rotation speed and hole depth.

- Follows ISO 22476-15 International Standard for MWD.

- All sensors utilized are common Geoprobe® components with proven experience and reliability.

- MWD sensors are easily integrated into existing rig electronics to maximize usefulness of sensor data being currently collected.

- Calibrated outputs are delivered to the data logger of your choice via J1939 CAN Bus network on the drill, simplifying the rig’s wiring.

Tooling & Accessories

Video: Interlocking Split Spoon Overview

Engineered to be stronger, last longer, and save money and time, the patented interlocking split spoon meets ASTM Standard D1586.The finger-like design self aligns, creating a perfect fit and quicker assembly. With the threads aligned, the cutting shoe and drive head can be threaded to the split spoon. Multi-lead threads require fewer turns during assembly and disassembly over conventional split spoons, speeding up each test interval.In additional to time savings, enhanced material properties and manufacturing result in greater longevity. Each interlocking point keeps the two tube halves engaged throughout the sampling process. The strength of these connections prevents the sampler from bulging in dense materials. It also keeps the tube halves tightly engaged even when over-filling of the sampler occurs.

Video: Geoprobe® Spring Assisted Swivel Lift Cap

The Spring Assisted Swivel Lift Cap is designed to reduce operator fatigue when adding or removing sections of rods to the inner tool string. The internal springs of the pull cap bear the weight of the rod string. With minimal effort, the operator can adjust the rod string up or down when threading or unthreading the rods. The natural self-alignment of the rod string prevents tipping off center and binding of the threads.

Video: Geoprobe® Macro-Core® Center Rod

Our MC5 Soil Sampling System is a single tube, discrete or continuous system with unmatched durability.MC5 Light Weight Center Rod Soil Sampling System. The MC5 1.25-inch Center Rod System was designed for the absolute worst of the worst direct push probing conditions. “These are conditions that we normally do not recommend probing in,” according to Mike Carlin, Project Engineer, “so we developed the toughest soil sampling system in the direct push industry ... it’s a brute!”Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Video: DT22 Soil Sampling System Overview

The Geoprobe® DT22 Soil Sampling System is a direct push system for collecting continuous core samples of unconsolidated materials from within a sealed casing of Geoprobe® 2.25- inch outside diameter probe rods. Samples are collected and retrieved within a liner that is threaded onto the leading end of a string of Geoprobe® 1.25-inch OD light-weight center rods and are inserted to the bottom of the outer casing.

The DT37 Soil Sampling System, designed for use with 3.75-inch probe rods, uses a unique combination of the cutting shoe, sheath, and liner retainer to allow efficient recovery of samples in formations ranging from plastic clays to saturated sands. The DT37 system is designed to quickly recover samples well below the water table. Problems with liner failure or having the liner lodge in sample sheath are virtually eliminated with this system.

Video: SP22-ISP Groundwater Sampler

The Screen Point 22 (SP22) Groundwater Sampler from Geoprobe Systems® was designed to keep the screen away from all percussive energy while the sampler is lowered downhole, thus extending the life of the screen.The SP22 can be used alone as a groundwater grab sampler or groundwater profiling tool, or with the DT22 Soil Sampling System. The screens can be deployed using either 1.25-inch Lightweight Center Rods or PVC riser.Designed for tough probing conditions, the screen head on the fully retrievable sampler adapts to either a stainless steel or PVC screen.

Applications

Environmental

Effectively compete in multiple revenue streams - HSA, SPT, CPT, DPT, rock coring, mud rotary, air rotary, and drive and wash - quickly maneuvering between bore holes on crawler carrier equipped with centerline head side shift mast which aligns all head and winch functions over bore hole.

Videos

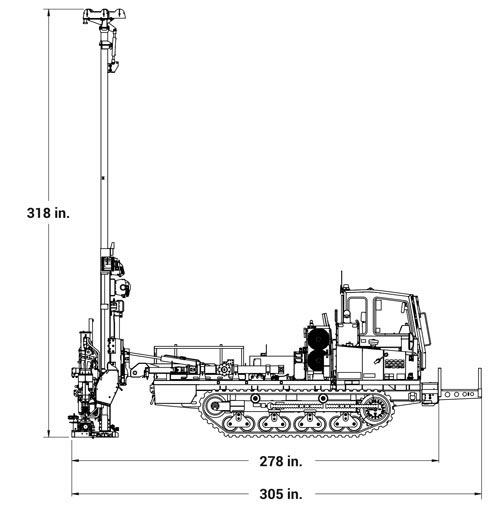

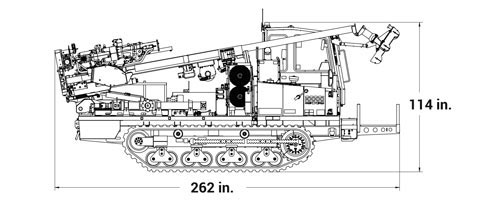

Specs

Specifications are subject to change without notice.

| 3145GT | 3145GT | ||||

|---|---|---|---|---|---|

| Overall Dimensions | units | units | |||

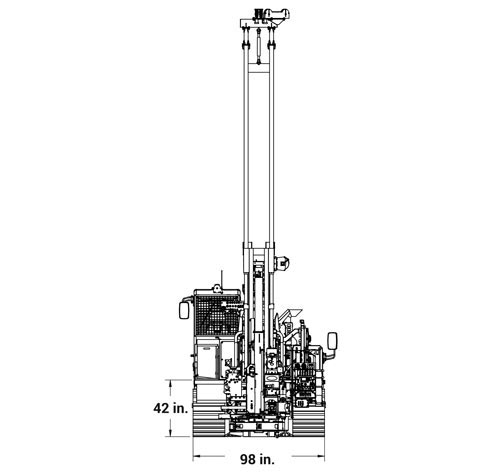

| Width | in | 98 | mm | 2489.2 | |

| Length (transport) | in | 261.5 | mm | 6642 | |

| Length (deployed, lateral fully extended) | in | 304.5 | mm | 7734 | |

| Height (normal transport) | in | 113.3 | mm | 2878 | |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| 3145GT | 3145GT | ||||

|---|---|---|---|---|---|

| Overall Dimensions | units | units | |||

| Width | in | 98 | mm | 2489.2 | |

| Length (transport) | in | 261.5 | mm | 6642 | |

| Length (deployed, lateral fully extended) | in | 304.5 | mm | 7734 | |

| Height (normal transport) | in | 113.3 | mm | 2878 | |

Operator Side - Unfolded

Operator Side - Folded

Unfolded

Resources

Click on a section below to view information.

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

3145GT on crawler carrier accesses remote sites while towing additional supplies and possessing capability to perform direct push, coring, and SPT.

ID: 14358 | Date:

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Tri State Drilling LLC operates 10 rigs on a daily basis providing environmental, geotechnical, and mineral exploration drilling services for engineering firms across the southeast from their offices in Chattanooga and Nashville, Tennessee. Four of their

ID: 13150 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.