DM250 Water Well Drill Rig

Video: DRILLMAX® DM250 Overview

Big Rig in a Small Package

Drillers seeking efficiency for water well drilling or geothermal drilling jobs choose the DRILLMAX® DM250 by Geoprobe® for its top head rotation speed combined with 20-foot stroke all under Class A/B CDL requirements. Additional advantages of the small water well drilling rigs for sale include:

- improved pressure consistency produced by mud pump

- enhanced ease and comfort created by durable, mechanical controls and wide driller platform

- increased production capability provided by the rod loader or rod carousel

Customers claim the DM250 is “faster, easier, and doubles production – even in tough clays.”

Features & Options

Video: DRILLMAX® DM250 Walkaround

Compact size and easy mobility mean getting to and through jobs fast while enjoying creature comforts of factory 4X4 chassis including air conditioning, cruise control, and bluetooth while minimizing fuel costs achieving 15 mpg on average.

Simple operation and surprising power provide fast production with 22-foot stroke. Choose from a wide range of options, tailoring your DM250 to your geography and production needs. Selecting from standardized options reduces hassle of routine maintenance and makes possible repairing your rig from the field with a phone call to our team of expert service technicians. Owners describe their DM250 as their most productive and versatile rig, praising its simple operation for making it easy to train new operators.

- Save money by mobilizing 200-feet of pipe while staying under class A/B CDL requirements, eliminating concerns over having enough 20-foot pipe to finish the job or having to find a CDL driver. The durable, mechanical controls stand the test of time, keeping you completing contracts rather than repairing rigs.

- Increase production thanks to the top head rotation speed combined with stroke for 20-foot tooling, quickly chewing up tough clays. Table assembly has clearance for 12-inch PVC casing and the holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe.

- Expand access with the compact size suited for residential work where limited access is a priority. No more worrying about tearing up driveways or yards makes this rig a smart choice for everyday use. Set up with centrifugal or piston mud pump and development air to meet your job needs.

Many who use the DM250 focus on drilling shallower than 300 feet, though the machine can exceed that depth. Key features on the small water well drilling rigs for sale make for quick, easy work of 2-inch to 6-inch water wells.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your small water well drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your small water well drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs for our DRILLMAX® small water well drilling rigs by Geoprobe®. Our goal is to make your job faster, safer, and easier. Partner with us and we'll work to decrease your water well drill downtime while increasing your family time.

Control Panel

Durable, mechanical controls well organized on DM250 for simple operation making training new drillers easier.

The durable, mechanical controls neatly laid out on the control panel include engine monitoring, a safety E-stop, hydraulic pressure gauges, holdback control, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

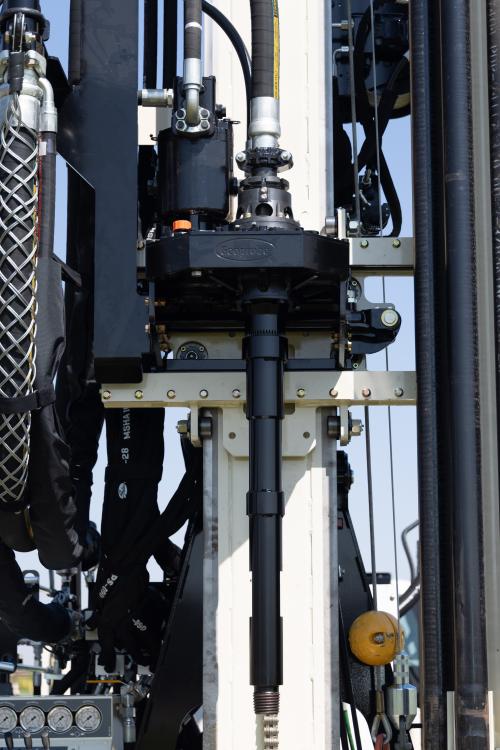

Top Head Carriage

Fast production with head speed and 20-foot stroke on the DM250

Video: DRILLMAX® DM250 - Top Head

Rollers for top head carriage on DM250 create quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Minimize time spent standing around waiting on cuttings to rise to top of hole thanks to the top head travel speed on the DM250. The fast travel time up and down the mast increases the uphole velocity pulling mud and cuttings up out of the hole. So rather than wasting time waiting on cuttings to come up out of a 300-foot deep well, you can move on to the next step.

- significantly cut time to clear cuttings from hole with top head travel speed.

- minimize time spent clearing mud and cuttings from hole to maximize production.

- trade less time standing and waiting for more time drilling and making money.

Mud Pump and Development Air Options

Production consistency on the small water well drilling rigs for sale possible by array of mud pump options.

The Geoprobe® DM250 can be set up with centrifugal or piston mud pump and development air to meet your job needs. Mud pump and air compressor options include 3L8, 5x5 duplex, centrifugal pumps, 85cfm, and 185/150 air compressor.

185/150 Air Compressor

For customers drilling bigger, deeper wells, Geoprobe® answers with the 185/150 air compressor. Higher output and efficiency mean faster hole development, cleaner wells, and full DM250 performance.

Auxiliary Air Connection

Extra air? No sweat. The DM250 is pre-plumbed for plug-and-play connection, so supplemental compressors hook up fast and keep drilling running smoothly.

Rod Loader and Helper Side Controls

Production from head speed on DM250 amplified by rod loader and helper side controls.

Video: DM250 Single Rod Loader

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single road loader. This makes the DM250 easy to operate with a two-man crew.

Table Assembly

Wide driller's platform on either side of DM250 table assembly creates comfort for drillers accessing up-to 12-inch casing from the controls.

Video: DRILLMAX® DM250 Hydraulic Table

The DM250 drill truck table assembly has clearance for 12-inch PVC casing. Table opening positioned outside rig permits placing casing without body contortions.

- easily access table opening positioned at back of rig rather than struggling to reach inside rig.

- contact casing while remain at control panel.

- remove bushings to set up to 12-inch casing.

F600 model comes standard with a hydraulic table, featuring:

- Bushing closest to mast incorporates hydraulic movement.

- Table slips to clamp and hold up-to 6-inch steel casing tight.

- Eliminates chattering pins in coarse sands and gravel for quieter job site.

Call about upgrade kits available for 2018 or newer rigs.

Breakout Wrench

Hydraulic breakout wrench on DM250 eases strain on drillers while making tripping out fast and safe.

The holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe.

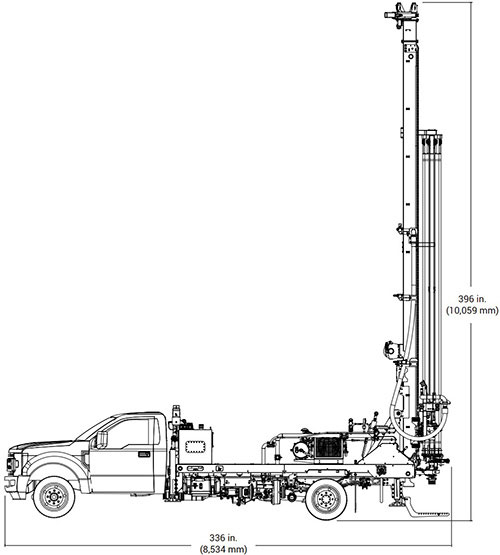

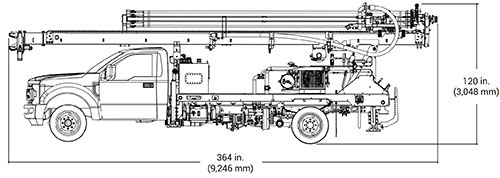

Truck Chassis

Small water well drilling rigs for sale cut costs by efficient mobilization under class A/B CDL.

Compact size and easy mobility mean getting to and into jobs fast and moving on to the next - whether off-road or a limited-access residential area - without worrying about having a CDL. Drillers enjoy the creature comforts of the factory 4X4 chassis, including air conditioning, cruise control, and bluetooth while minimizing fuel costs achieving 15 mpg on average. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

The newest model DM250 on Ford F600 incorporates a number of those requests, including:

INCREASED REAR OUTRIGGER STROKE by 10 inches, providing more clearance to push and pull conductor pipe.

BETTER GROUND CLEARANCE provided by pads sitting 4.5-inches higher and split shaft sitting higher, improving ability to access job sites.

IMPROVED HYDRAULICS including:

- increased cooling capabilities.

- adjustable holdback improving control of down-the-hole hammer when driving casing and finer adjustments to see formation change when completing gravel pack wells.

- improved auxiliary hydraulics for increased flexibility when choosing rig options.

Rod Carousel

Arrow marker and machined grooves aid aligning rotary head over rods.

Video: DRILLMAX® DM250 - Rod Carousel

Safe carousel option promptly pays for itself carrying 160-feet of 3-inch drill pipe.. Eliminate worry whether helper will call in sick when you choose carousel option that shows up everyday.

- create opportunity to task helper with other site chores or run a one-man operation.

- pipe locks into position within pod canceling chance pipe falls out.

- rotate carousel to place indicator arrow between grooves on base, push handle, and lock carousel into position for safe travel.

- mechanical alignment of top head with rods using indicator arrow and grooves on base eliminates need for electrical sensor that could malfunction.

On-board Grout Mixer

On-board grout mixer saves fuel compared to running a separate engine.

40-gallon on-board grout mixer runs off of rig hydraulics, saving fuel compared to running an extra engine.

Stabilizer Tray or Small Rod Box

Stabilizer tray along deck for storage.

Stabilizer tray simplifies storage on rig and provides user-friendly access. Or choose a small rod box to transport an additional 100-feet of 3-inch drill pipe to back feed into carousel instead of a adding a stabilizer tray.

Ford F600

DM250 small water well drilling rigs for sale on Ford F600 chassis

Drillers across the country using the DM250 for their water well and geothermal work have been fueling our engineers with ideas and suggestions for improvements. In ongoing efforts to make drilling faster, easier, and safer the newest model DM250 on Ford F600 incorporates a number of those requests, including:

- STANDARD HYDRAULIC TABLE

- INCREASED REAR OUTRIGGER STROKE by 10 inches, providing more clearance to push and pull conductor pipe.

- BETTER GROUND CLEARANCE provided by pads sitting 4.5-inches higher and split shaft sitting higher, improving ability to access job sites.

- IMPROVED HYDRAULICS including: increased cooling capabilities, adjustable holdback improving control of down-the-hole hammer when driving casing and finer adjustments to see formation change when completing gravel pack wells, improved auxiliary hydraulics for increased flexibility when choosing rig options.

Features & Options

Video: DRILLMAX® DM250 Walkaround

Simple operation and surprising power provide fast production with 22-foot stroke. Choose from a wide range of options, tailoring your DM250 to your geography and production needs. Selecting from standardized options reduces hassle of routine maintenance and makes possible repairing your rig from the field with a phone call to our team of expert service technicians. Owners describe their DM250 as their most productive and versatile rig, praising its simple operation for making it easy to train new operators.

- Save money by mobilizing 200-feet of pipe while staying under class A/B CDL requirements, eliminating concerns over having enough 20-foot pipe to finish the job or having to find a CDL driver. The durable, mechanical controls stand the test of time, keeping you completing contracts rather than repairing rigs.

- Increase production thanks to the top head rotation speed combined with stroke for 20-foot tooling, quickly chewing up tough clays. Table assembly has clearance for 12-inch PVC casing and the holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe.

- Expand access with the compact size suited for residential work where limited access is a priority. No more worrying about tearing up driveways or yards makes this rig a smart choice for everyday use. Set up with centrifugal or piston mud pump and development air to meet your job needs.

Many who use the DM250 focus on drilling shallower than 300 feet, though the machine can exceed that depth. Key features on the small water well drilling rigs for sale make for quick, easy work of 2-inch to 6-inch water wells.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your small water well drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your small water well drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs for our DRILLMAX® small water well drilling rigs by Geoprobe®. Our goal is to make your job faster, safer, and easier. Partner with us and we'll work to decrease your water well drill downtime while increasing your family time.

The durable, mechanical controls neatly laid out on the control panel include engine monitoring, a safety E-stop, hydraulic pressure gauges, holdback control, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

Rollers for top head carriage on DM250 create quiet, smooth head travel with simple maintenance.

- long-lasting rollers are easily adjusted.

- rollers permit fast and safe top head travel.

- easy maintenance keeps rig performing like new.

Minimize time spent standing around waiting on cuttings to rise to top of hole thanks to the top head travel speed on the DM250. The fast travel time up and down the mast increases the uphole velocity pulling mud and cuttings up out of the hole. So rather than wasting time waiting on cuttings to come up out of a 300-foot deep well, you can move on to the next step.

- significantly cut time to clear cuttings from hole with top head travel speed.

- minimize time spent clearing mud and cuttings from hole to maximize production.

- trade less time standing and waiting for more time drilling and making money.

Video: DRILLMAX® DM250 - Top Head

The Geoprobe® DM250 can be set up with centrifugal or piston mud pump and development air to meet your job needs. Mud pump and air compressor options include 3L8, 5x5 duplex, centrifugal pumps, 85cfm, and 185/150 air compressor.

185/150 Air Compressor

For customers drilling bigger, deeper wells, Geoprobe® answers with the 185/150 air compressor. Higher output and efficiency mean faster hole development, cleaner wells, and full DM250 performance.

Auxiliary Air Connection

Extra air? No sweat. The DM250 is pre-plumbed for plug-and-play connection, so supplemental compressors hook up fast and keep drilling running smoothly.

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single road loader. This makes the DM250 easy to operate with a two-man crew.

Video: DM250 Single Rod Loader

The DM250 drill truck table assembly has clearance for 12-inch PVC casing. Table opening positioned outside rig permits placing casing without body contortions.

- easily access table opening positioned at back of rig rather than struggling to reach inside rig.

- contact casing while remain at control panel.

- remove bushings to set up to 12-inch casing.

F600 model comes standard with a hydraulic table, featuring:

- Bushing closest to mast incorporates hydraulic movement.

- Table slips to clamp and hold up-to 6-inch steel casing tight.

- Eliminates chattering pins in coarse sands and gravel for quieter job site.

Call about upgrade kits available for 2018 or newer rigs.

Video: DRILLMAX® DM250 Hydraulic Table

The holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe.

Compact size and easy mobility mean getting to and into jobs fast and moving on to the next - whether off-road or a limited-access residential area - without worrying about having a CDL. Drillers enjoy the creature comforts of the factory 4X4 chassis, including air conditioning, cruise control, and bluetooth while minimizing fuel costs achieving 15 mpg on average. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

The newest model DM250 on Ford F600 incorporates a number of those requests, including:

INCREASED REAR OUTRIGGER STROKE by 10 inches, providing more clearance to push and pull conductor pipe.

BETTER GROUND CLEARANCE provided by pads sitting 4.5-inches higher and split shaft sitting higher, improving ability to access job sites.

IMPROVED HYDRAULICS including:

- increased cooling capabilities.

- adjustable holdback improving control of down-the-hole hammer when driving casing and finer adjustments to see formation change when completing gravel pack wells.

- improved auxiliary hydraulics for increased flexibility when choosing rig options.

Safe carousel option promptly pays for itself carrying 160-feet of 3-inch drill pipe.. Eliminate worry whether helper will call in sick when you choose carousel option that shows up everyday.

- create opportunity to task helper with other site chores or run a one-man operation.

- pipe locks into position within pod canceling chance pipe falls out.

- rotate carousel to place indicator arrow between grooves on base, push handle, and lock carousel into position for safe travel.

- mechanical alignment of top head with rods using indicator arrow and grooves on base eliminates need for electrical sensor that could malfunction.

Video: DRILLMAX® DM250 - Rod Carousel

40-gallon on-board grout mixer runs off of rig hydraulics, saving fuel compared to running an extra engine.

Stabilizer tray simplifies storage on rig and provides user-friendly access. Or choose a small rod box to transport an additional 100-feet of 3-inch drill pipe to back feed into carousel instead of a adding a stabilizer tray.

Drillers across the country using the DM250 for their water well and geothermal work have been fueling our engineers with ideas and suggestions for improvements. In ongoing efforts to make drilling faster, easier, and safer the newest model DM250 on Ford F600 incorporates a number of those requests, including:

- STANDARD HYDRAULIC TABLE

- INCREASED REAR OUTRIGGER STROKE by 10 inches, providing more clearance to push and pull conductor pipe.

- BETTER GROUND CLEARANCE provided by pads sitting 4.5-inches higher and split shaft sitting higher, improving ability to access job sites.

- IMPROVED HYDRAULICS including: increased cooling capabilities, adjustable holdback improving control of down-the-hole hammer when driving casing and finer adjustments to see formation change when completing gravel pack wells, improved auxiliary hydraulics for increased flexibility when choosing rig options.

“The way the machine is set up makes it less cumbersome on the driller and helper as a whole. Just makes life easier."

- Tabatha Westberry, Office Manager, Moore’s Well Drilling, Georgia

Applications

Videos

ID: 14042

ID: 14040

ID: 13965

DRILLMAX® DM250 Hydraulic Table

ID: 13358

ID: 9588

ID: 9589

DRILLMAX® DM250 - Rod Carousel

ID: 9583

ID: 5343

DM250 Ram 5500 Compressor Startup

ID: 13629

Specs

Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

|---|---|---|---|---|

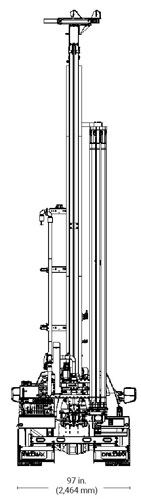

| Width (in) | 97 | Width (mm) | 2464 | |

| Length (transport) (in) | 364 | Length (transport) (mm) | 9246 | |

| Length (transport) (ft) | 30.3 | Length (transport) (m) | 9.25 | |

| Length (deployed) (in) | 336 | Length (deployed) (mm) | 8534 | |

| Height (normal transport) (in) | 120 | Height (normal transport) (mm) | 3048 | |

| Height (deployed) (in) | 396 | Height (mm) | 10058 | |

| Height (deployed) (ft) | 33 | Height (deployed) (m) | 10.06 | |

| Base Unit Weight (lbs) | 20,000 | Base Unit Weight (kg) | 9,072 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 26 | Front outrigger travel (mm) | 660 | |

| Rear outrigger travel (in) | 26 | Rear outrigger travel (mm) | 660 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 264 | Head Travel (mm) | 6706 | |

| Head Travel (ft) | 22 | Head Travel (m) | 6.71 | |

| Head Crowd Force (lbs) | 6,700 | Head Crowd Force (kN) | 30 | |

| Head Pull Force (lbs) | 12,000 | Head Pull Force (kN) | 53 | |

| Head Side shift (in) | 12 | Head Side shift (mm) | 305 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Ford F600 4X4 | Truck | Ford F600 4X4 | |

| Engine | 6.7L Powerstroke® Turbo Diesel Engine | Engine | 6.7L Powerstroke® Turbo Diesel Engine | |

| Engine Rated Power (hp)* | 330 | Engine Rated Power (kW) | NA | |

| Fuel Capacity (gal) | 40 | Fuel Capacity (L) | 151 | |

| Rotary Drive Options | Rotary Drive Options | |||

| Single-Speed Rotary Drive | DMR3HT (Standard) | Single-Speed Rotary Drive | DMR3HT (Standard) | |

| Rotation Torque (ft-lb) | 2185 | Rotation Torque (N-m) | 2962 | |

| Rotation Speed (rpm) | 245 | Rotation Speed (rpm) | 245 | |

| Single-Speed Rotary Drive | DMR3HS | Single-Speed Rotary Drive | DMR3HS | |

| Rotation Torque (ft-lb) | 1064 | Rotation Torque (N-m) | 1443 | |

| Rotation Speed (rpm) | 300 | Rotation Speed (rpm) | 300 | |

| Primary Winch | Primary Winch | |||

| line pull (lbf) | 5000 | line pull (kN) | 22.24 | |

| line speed (fpm) | 130 | line speed (m/min) | 40 | |

| cable length (ft) | 80 | cable length (m) | 24 | |

| Secondary Winch (Optional) | Secondary Winch (Optional) | |||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 145 | line speed (m/min) | 44 | |

| cable length (ft) | 425 | cable length (m) | 130 | |

| line pull (lbf) | 1100 | line pull (kN) | 4.89 | |

| line speed (fpm) | 145 | line speed (m/min) | 44 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Breakout | Breakout | |||

| Table Opening (in) | 14 | Table Opening (mm) | 356 | |

| Single Clamp | Single Clamp | |||

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8135 |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | |||

|---|---|---|---|---|

| Width (in) | 97 | Width (mm) | 2464 | |

| Length (transport) (in) | 364 | Length (transport) (mm) | 9246 | |

| Length (transport) (ft) | 30.3 | Length (transport) (m) | 9.25 | |

| Length (deployed) (in) | 336 | Length (deployed) (mm) | 8534 | |

| Height (normal transport) (in) | 120 | Height (normal transport) (mm) | 3048 | |

| Height (deployed) (in) | 396 | Height (mm) | 10058 | |

| Height (deployed) (ft) | 33 | Height (deployed) (m) | 10.06 | |

| Base Unit Weight (lbs) | 20,000 | Base Unit Weight (kg) | 9,072 | |

| Drill Mast Positioning | Drill Mast Positioning | |||

| Front outrigger travel (in) | 26 | Front outrigger travel (mm) | 660 | |

| Rear outrigger travel (in) | 26 | Rear outrigger travel (mm) | 660 | |

| Drill Mast Specifications | Drill Mast Specifications | |||

| Head Travel (in) | 264 | Head Travel (mm) | 6706 | |

| Head Travel (ft) | 22 | Head Travel (m) | 6.71 | |

| Head Crowd Force (lbs) | 6,700 | Head Crowd Force (kN) | 30 | |

| Head Pull Force (lbs) | 12,000 | Head Pull Force (kN) | 53 | |

| Head Side shift (in) | 12 | Head Side shift (mm) | 305 | |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | |||

| Truck | Ford F600 4X4 | Truck | Ford F600 4X4 | |

| Engine | 6.7L Powerstroke® Turbo Diesel Engine | Engine | 6.7L Powerstroke® Turbo Diesel Engine | |

| Engine Rated Power (hp)* | 330 | Engine Rated Power (kW) | NA | |

| Fuel Capacity (gal) | 40 | Fuel Capacity (L) | 151 | |

| Rotary Drive Options | Rotary Drive Options | |||

| Single-Speed Rotary Drive | DMR3HT (Standard) | Single-Speed Rotary Drive | DMR3HT (Standard) | |

| Rotation Torque (ft-lb) | 2185 | Rotation Torque (N-m) | 2962 | |

| Rotation Speed (rpm) | 245 | Rotation Speed (rpm) | 245 | |

| Single-Speed Rotary Drive | DMR3HS | Single-Speed Rotary Drive | DMR3HS | |

| Rotation Torque (ft-lb) | 1064 | Rotation Torque (N-m) | 1443 | |

| Rotation Speed (rpm) | 300 | Rotation Speed (rpm) | 300 | |

| Primary Winch | Primary Winch | |||

| line pull (lbf) | 5000 | line pull (kN) | 22.24 | |

| line speed (fpm) | 130 | line speed (m/min) | 40 | |

| cable length (ft) | 80 | cable length (m) | 24 | |

| Secondary Winch (Optional) | Secondary Winch (Optional) | |||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 | |

| line speed (fpm) | 145 | line speed (m/min) | 44 | |

| cable length (ft) | 425 | cable length (m) | 130 | |

| line pull (lbf) | 1100 | line pull (kN) | 4.89 | |

| line speed (fpm) | 145 | line speed (m/min) | 44 | |

| cable length (ft) | 750 | cable length (m) | 229 | |

| Breakout | Breakout | |||

| Table Opening (in) | 14 | Table Opening (mm) | 356 | |

| Single Clamp | Single Clamp | |||

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8135 |

Operator - Unfolded

Operator - Folded

Unfolded

Resources

Click on a section below to view information.

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date:

Canadian geothermal energy company chooses DM250 features like size-to-power ratio when expanding into vertical residential, small commercial geothermal installation.

ID: 14590 | Date:

Compact DM250 slips into tight residential lots, satisfying customers particular about their landscaping.

ID: 14589 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.