GP800

What is this pump used for?

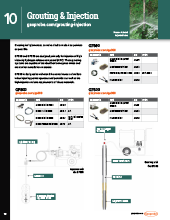

The GP800 injection pump was designed to pump chemicals that are injected in high volumes where low volume/high pressure pumps are not well suited. At 8 gpm, the GP800 can pump most chemicals 2-3 times faster than the Geoprobe® GS Series grout machines. With acids, the need for a high volume/medium pressure pump is evident. The GP800 fits this need.

What should I NOT pump with this grout machine?

ORC®, Bentonite Grout, HRC®, Cement, or any material that has ability to set up in a hardened state when dehydrated or dried. Materials such as HRC® or molasses should not be pumped due to their high viscosity, nor should ORC® and cement-based grouts due to their tendency to harden inside the pump.

How do I deliver material to the pump?

While the GP800 injection pump is self-priming, an elevated, gravity-fed supply is recommended to prevent pump cavitation. Situate the GP800 close to the supply source … within 3 feet is ideal. The pump is supplied with a 1.0 in. PVC supply hose assembly.

How does the injection pump operate?

The pump is driven by a 9HP Honda engine with 2:1 gear reduction and centrifugal clutch. The pump will operate at most engine speeds.

How much time is required for cleanup?

Cleanup is fairly straightforward. After pumping is complete, simply allow clean water to run through the pump at high speed for several minutes. This flushes any residual chemicals or materials out of the pump.

(ORC® and HRC® are registered trademarks of Regenesis Bioremediation Products, San Clemente, CA.)

Knowing when to use this pump is important to the performance of this machine. As with all Geoprobe® tools and equipment, it's important to remember Team Geoprobe® is ready to answer any question you may have about tool/machine usage.

Features

- Mobile... compact

- Few replaceable parts

- High volume ... 8 gpm

- Outlet pressure... 650 psi

- Operates independently of probe machine

- Use without vehicle nearby

- Optional suction hose designed to withstand harsh oxidants

- Optional outlet hose is Teflon® lined with stainless steel jacket to withstand oxidants

- Capable of "bottom up" or "top down" injections

- Self-priming pump

- Internal components of pump resistant to harsh oxidants, such as permanganates

- All mechanical operation -- no electronics on boar

Specs

| Standard | Metric | ||||

|---|---|---|---|---|---|

| Weight | 182 lb. | 83 kg | |||

| Pump Type | Shaft-driven triple diaphragm pump | ||||

| Power Source Engine | Honda Model GX270 | ||||

| Engine Fuel Capacity | 1.59 gal. | 6.0 L | |||

| Engine Horsepower | 9.0 Hp gasoline | ||||

| Pump Displacement | 0.00046 gal/rev | 0.017 L/rev | |||

| Pump Oil Capacity | 1.1 qts. | 1.05 L | |||

| Pressure Rating (max) | 650 psi | 45 bar | |||

| Flow Rate | 8.0 gpm | 30.3 Lpm | |||

Resources

GP800

Inject materials laterally into the subsurface with either top-down or bottom-up injection.

Outlet Hose Assembly - Teflon® with stainless steel jacket

GP800

GP800

The GP800 is powered by a Honda 9.0 Hp gasoline engine providing up to 650 psi of pressure.

Parts

To order parts or to get a quote, click here.

You will have the option to order immediately (pending payment) or get a quote.

MN: 213991

6 ft.

MN: 203471

15 ft., Stainless Steel Jacket

MN: 203472

4 ft.

MN: 203837

MN: 213991

6 ft.

MN: 203471

15 ft., Stainless Steel Jacket

MN: 203472

4 ft.

MN: 203837