Working Together for Success

You operate in an ever-changing business climate, and we're dedicated to helping you not only survive but thrive amid those changes. When rigs and drilling tooling are designed, built and supported as one, the end result is a highly-refined system escalating efficiency and profitability.

Engineered Systems: Effective drilling depends on both the drill rig and drilling tooling

Geoprobe® drill rig engineers work at arm's length from our drilling tooling engineers, sharing office and shop space - intentionally. The synergy from shared office and shop space results in innovative responses to customer feedback on both sides of the system.

Hands-on Engineers: Designing rigs and drilling tooling requires more than sitting behind a desk discussing drawings

Our engineers are in the field, testing drilling tooling in job site scenarios and putting their own drilling experience to work field testing rigs. They get dirty ensuring their tooling and rig designs make your job faster, easier, and safer. They work alongside our skilled manufacturing shop technicians to ensure product quality and performance. They partner with service technicians to perform rig repairs in the shop or in the field. They collaborate with you – the customer in the field – to identify improvements and innovations for the next generation of Geoprobe® rigs and tooling. Our engineers’ hands-on approach to their work benefits you through:

ENGINEERED PRODUCT: dedicated team focused solely on drilling tooling

FIELD TESTED: tested in job site scenarios by engineers

PROBLEM SOLVERS: product innovation based on user feedback

Manufactured by Geoprobe®: Consistent, durable drilling tooling merits quality control of in-house manufacturing

Most Geoprobe® tooling and machine components are manufactured at our Salina, Kansas, headquarters. With the goal of producing the best possible soil probing and drilling equipment, our production system leverages individual skills and specialized manufacturing tools to ensure consistent, high-quality products so you achieve reliable and accurate project results. From metal to machine, our motivated manufacturing team goes the extra mile to conquer challenges and produce products on time to meet your needs. We encourage you to come on a factory tour and see for yourself how our production system distinguishes our product from the competition.

Choose from a wide assortment of tooling options designed and manufactured by Geoprobe® to achieve reliable and consistent project results. We invest in state-of-the-art manufacturing processes to produce a wide-array of drilling tooling to collect high-quality information with same-day shipping available on most parts.

Industry-leading Support: Customer-focused team composed of problem solvers produces solutions

You operate in an ever-changing business climate, and we’re dedicated to helping you thrive. Being an asset to our clients – and potential customers – includes assessing your needs to recommend appropriate rigs and tooling, talking through technical advice on drilling and sampling techniques, walking through rig repairs in the field via a team of live phone support service technicians, supplying same-day shipping on most parts, and staffing service centers across the country with expert technicians, specialty tools, and parts inventory to complete rig repairs to complete rig refurbishments.

Customers are confident of rapid response to their requests — often in hours not days. We also continually update our video library to provide you with maintenance and tooling technique tips. Our customer focused work ethic means you get:

RELIABILITY: 30-year proven record in the industry

AVAILABILITY: in stock and capable of shipping same day

SUPPORT: experienced team with knowledge to provide advice

Satisfied Customers: Delivering on promises keep customers returning to Geoprobe®

We’re about more than just steel and almond paint – when you succeed, we succeed. Customers rely on our quality rigs and tooling for extracting high-quality soil, groundwater, and rock samples in a safe and efficient manner. Customers ultimately realize cost savings using our durable products to perform repeatedly under pressure, minimizing replacement frequency. The benefits of Genuine Geoprobe® tooling according to customers, include:

Makes jobs easier with tooling engineers streamlining sampling

Outperforms most drilling tooling in the industry

Survives years of use thanks to durability

Comes out of the package working

Enables advising customers on best approach due to array of items

Keeps inventory costs down with same-day shipping

Manufactured in the United States

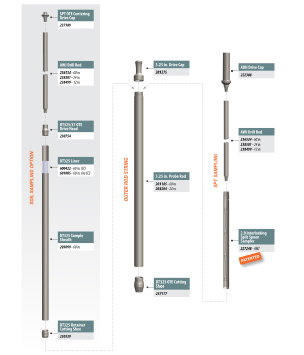

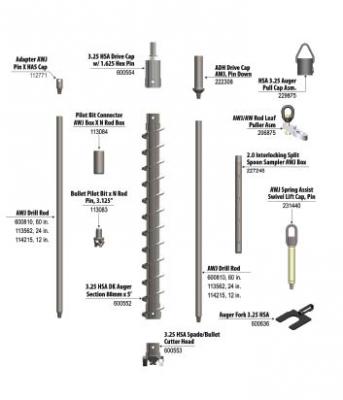

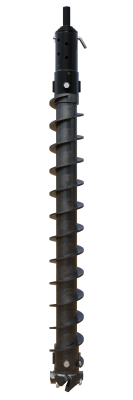

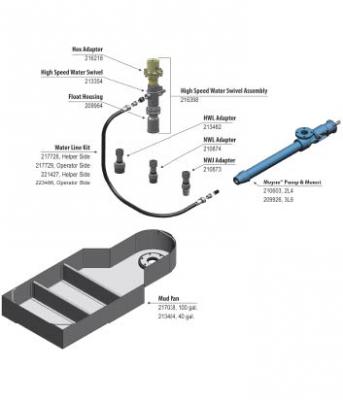

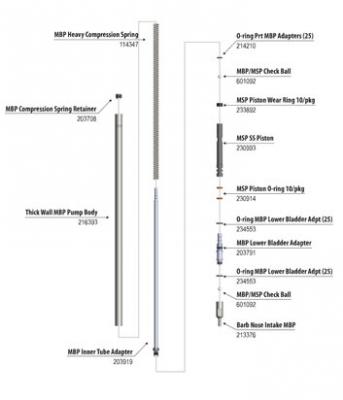

The below drilling tooling pages and tool string diagrams are a quick access guide for Geoprobe® drilling tooling systems.

Quote / Order Cart

To order parts or to get a quote, click here.

You will have the option to order immediately (pending payment) or get a quote.

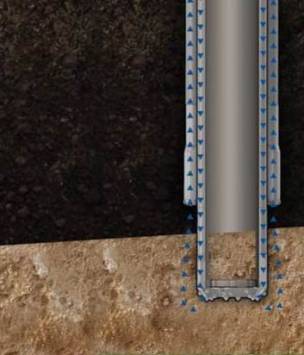

Direct Push Tooling

Soil Sampling Systems (Direct Push)

Geotechnical Tooling

Geotechnical Sampling

Hollow Stem Augers & Frost Augers

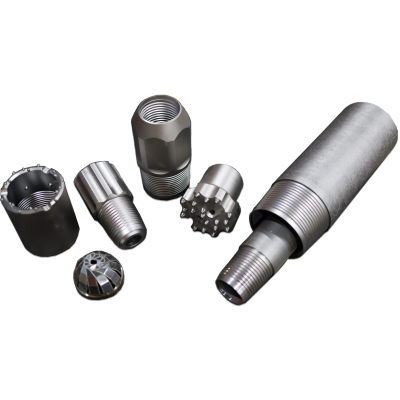

Rock Coring & Wet Rotary Systems

Concrete Coring & Penetrator Systems

Goundwater Sampling & Monitoring (Direct Push)

Soil Vapor Implants & Post Run Tubing System

Grouting & Injection

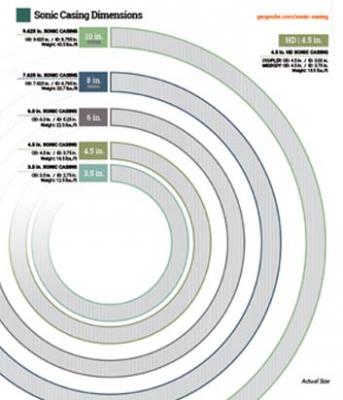

Sonic Tooling

Sonic Soil & Groundwater Sampling

Water Well Tooling

We're still using tooling from early 2000 that hasn't broken. We don't need a bunch of excess tooling around, because it lasts. If we need something, Geoprobe® can get it out to us immediately.

Xavier Green, Project Manager, Penecore Drilling, California