MWD

Utilize Available Rig Metrics to Collect More Accurate Data

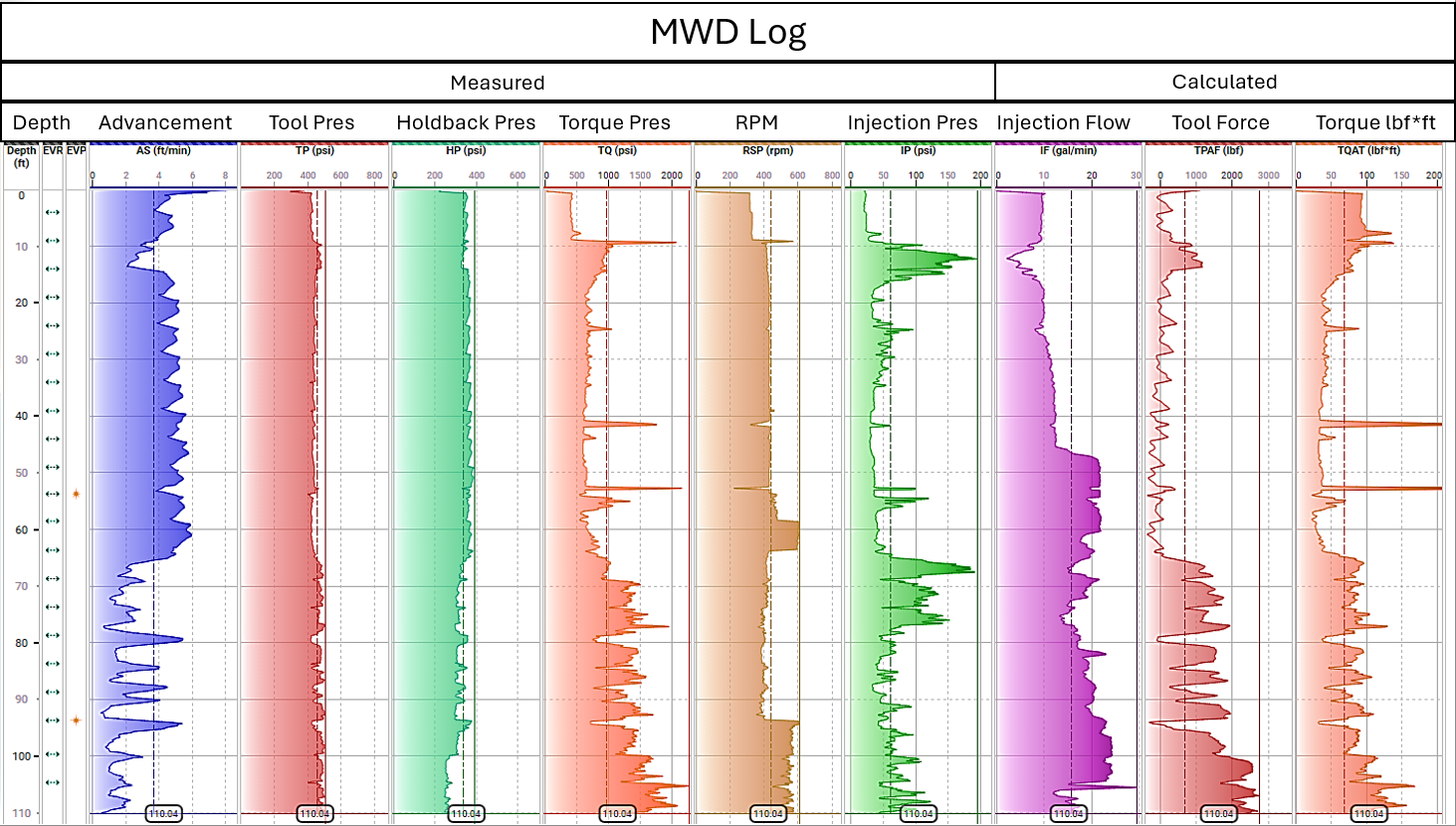

Measurement While Drilling (MWD) is a method of collecting digital data from the drill rig to log or record parameters pertaining to drilling operation. These methods are common in parts of the world where it has been standard to log or measure drilling parameters in the oil, gas, and mining industries.

Starting in 2024, Geoprobe® 31 Series geotechnical drill rigs are MWD capable. The option can be added at any time to include an MWD kit that allows drilling parameters to be recorded. Electrical harness, mounting points, and programming are already in place.

"Traditional geotechnical exploration would be to conduct SPT, which has been standardized to have correlations tied to the data collected. It's a discrete method, only capturing data at 5-foot intervals," said Alex Silvey from Nebraska Department of Roads. "MWD fills in the picture between samples. By paying attention to rig feedback, we can detect finer changes in material properties and identify accurate changes in lithology versus relying on an experienced driller to notice it by feel or missing important property changes in between intervals."

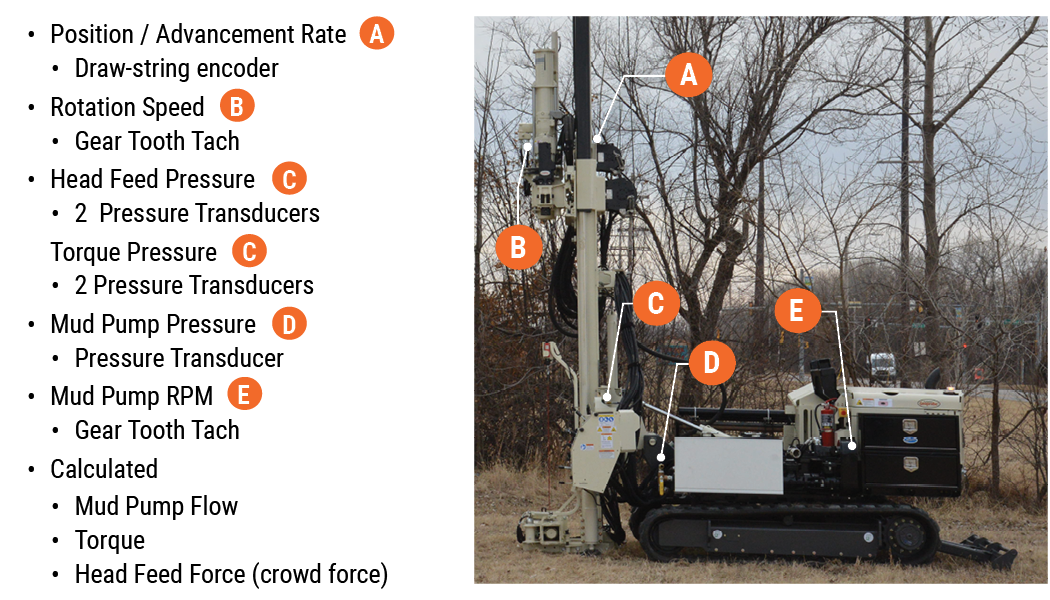

- Common parameters for MWD are crowd force, torque, penetration rate, mud pump pressure, mud flow rate, holdback pressure, head rotation speed, and hole depth.

- Follows ISO 22476-15 International Standard for MWD.

- All sensors utilized are common Geoprobe® components with proven experience and reliability.

- MWD Sensors are easily integrated into existing rig electronics to maximize usefulness of sensor data being currently collected.

- Calibrated outputs are delivered via J1939 CAN Bus network on the drill. This simplifies the wiring on the drill and can be supplied to a data logger of your choice.

- Expansion by adding other sensors is possible and can be read into the same data logger.

FIELDWORK SIMPLIFIEDTM

- Utilizes sensors installed and integrated by Geoprobe® for a reliable and supportable system

- Follows ISO Std. 22476-15 (hydraulic drills and measurements)

- Measurements and calculations are acquired by the rig

- Measured and calculated parameters are output by CAN Bus J1939 for easy integration into a LIM or other third party MWD data logger

- Used for recording drilling and operation parameters, identifying course lithology changes, identifying voids in soil or rock, etc.

MWD Measurements

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.