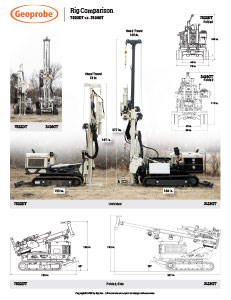

3126GT Geotechnical Drill Rig

Video: Geoprobe® 3126GT Overview

Drill More. Make More.

Drillers seeking to position for increased productivity and profit choose the 3126GT geotechnical drill with its innovative centerline head side shift and separate hydraulic circuit for mud pump. Engineered for efficiency in a small footprint on wide tracks, these compact geotechnical drilling rigs for sale nimbly navigate off-road without sacrificing power or versatility. The end result – faster, easier, and safer drilling.

- trim time between applications with six functions along the centerline head side shift

- reduce strain of rotary work with hands-free rotation and feed

- maximize production and rig utilization with power and versatility

Multifunctional Geotechnical Drill

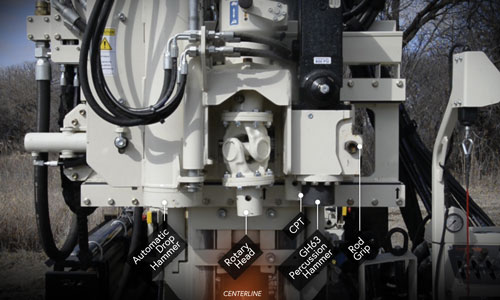

Advance augers with the 4 or 6-speed rotary head. Then use the geotechnical drill hydraulics to slide the head over to position the hands-free automatic drop hammer for driving SPT samples between core runs. Or use the geotechnical drill controls to slide the head the other way to conduct CPT logging using the integrated CPT head-feed rate controls complete with cone overload protection. Or use the integrated GH63 direct push hammer for fast and easy direct push soil and water sampling in unconsolidated formations — with your feet safely on the ground. No moving drill mast or machine.

Drill Rig Telemetry

Use NEW drill rig telemetry to view live data from your machines. Monitor rig location, hours, fuel use, and error codes without leaving the office. Stay ahead of maintenance and track performance to keep every rig at its best.

Features & Options

Video: Geoprobe® Walkaround: The 3126GT Drill Rig

Geotechnical drill makes for fieldwork simplified with centerline head side shift placing all drilling functions over bore hole without moving mast or machine.

Owners praise their Geoprobe® 3126GT geotechnical drill for its simplicity and safety so new drillers quickly travel the learning curve. Veteran drillers appreciate the attention to features addressing their field needs. Together all the standard features and available options minimize operating costs and come in at a price point lower than you might anticipate.

- ENGINEERED FOR EFFICIENCY: with six functions along the centerline, use machine hydraulics and controls to side-shift the head, simplifying your geotech applications. Complete augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT — even direct push — without manipulating mast position or mobilizing multiple machines.

- ENHANCED EASE AND SAFETY: boost geotechnical drill output and utilization with hands-free automatic drop hammer and integrated CPT head-feed rate control, including cone overload protection. Leverage small footprint to expand site access without sacrificing flow from mud pump or accessory storage. Bring new drillers up the learning curve quickly with easy controls and integrated safety features built to internationally-accepted standards.

- ELEVATED SERVICE AND SUPPORT: respond to your clients needs, making a quick call to get answers to your field and geotechnical drill service questions with overnight part shipping available from industry-leading support team.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your geotechnical drill is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new geotechnical drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Geotech Head

Six functions, including winches, along centerline with head side shift

Six functions along the 28-inch centerline head side shift simplify traditional geotechnical applications — augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT – and even direct push. Features GH63 percussion hammer 4-speed rotary head with 4,000 ft-lb, DH104 hands-free automatic drop hammer, CPT push/pull assembly, and a rod grip pull system. Head shifting speeds up drilling and minimizes the time driller spends in danger zone.

Hands-free Automatic Drop Hammer

Automatic drop hammer on 3126GT geotechnical drill includes a measuring marker

With 170-lb, 300-lb, or 340-lb options, the hands-free automatic drop hammer reduces strain when driving SPT samples. Advance borings for SPT testing by augering, driven casing and sampling, or wash boring.

Telescoping Winch Mast/Drill Mast Oscillation

Taller telescoping winch mast on 3126GT specifically designed for geotech work

The winch mast telescopes into place, allowing for flexible height options based on work environment. This also adds a layer of safety during setup when working near overhead power lines or other obstacles.

Taller telescoping winch mast specifically designed for geotech work with heavier winch options, 105-inches head travel, and 36,000-lbf push and 48,000-lbf pull at the head-feed cylinder means greater pull back – ideal for drive and wash – and head travel. Allows tripping out of 20-foot lengths of rod when combined with 3-foot extension.

Align the probe cylinder and tool string on a straight – or angled – path to the subsurface while the machine remains stable with the built-in oscillation, standard on all machines.

Drill mast features extend, swing, mast dump, oscillation, and fold. Mast dump provides 36.5 inches of vertical travel to allow room for a mud pan. Optional outriggers available.

Winch Options

Dual winches typically configured with 6,000-lbf and 1,800-lbf

A dual winch option is typically configured with a 6,800-lbf winch for the more difficult pulling and an 1,800-lbf. with quick-change hook. When ready to switch from pulling to coring, simply swap out the swivel hook for the overshot clevis installed on your overshot and continue working. It’s quick, simple, and can all be done by hand.

Additional winch options include 2,500-lbf and 1,100-lbf.

Also available is a third winch with 1,100 lbs of line pull, well suited to trip additional tooling out of the hole. Equipped with the Geoprobe® exclusive quick change hook, operators can switch over to wireline coring in seconds.

Higher Torque Rotary Head

GR6.5 Rotary Head provides 70 percent more torque

Video: Geoprobe® 3126GT Mud Rotary Drilling

While customers are proving the rock coring capabilities of the 4-speed rotary head on the 3126GT, some customers have requested more bottom-end torque for their geotech jobs. True to form, Geoprobe® responded by designing the 6-speed GR6.5 rotary head with 70 percent more torque.

"The GR6.5 has 6,800 ft-lbs of torque, which is 2,800 ft-lbs more than the GR4.1 on a typical 7822DT, without sacrificing top-end speed (720 rpm)," Ryan Kejr, machine engineer lead, said. "We also added an additional intermediate-speed range, which further enhances the unit's wet and air rotary capabilities."

Control Panel

Controls include hands-free rotary and head feed

All functions are at your fingertips in a well-organized, compact control panel. The systems display provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Hands-free rotary and head feed controls on the 3126GT reduce strain on driller when completing applications like mud rotary. CPT feed rate and hydraulic limit functions are standard.

7-inch Single Clamp Breakout

Breakout on 3126GT geotechnical drill has a clamp force of up to 21,000 pounds of force

The 7-inch single breakout firmly grips casing with a clamp force of up to 21,000 pounds of force. The breakout can be positioned either under the hammer or the rotary drive, as well as swung away from the machine.

An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

Tooling Transportation/Storage

Toolboxes help with site housekeeping while rear blade on 3126GT geotechnical drill easily transports tooling drop rack

The rear blade can be used for tool transport. During site setup, a tooling drop rack can be placed in front of the machine for easy access. This eliminates the need to walk around the machine for tooling, which saves time and conserves energy in the field.

Ample, well-spaced storage includes two stacked tool boxes, helper-side storage compartments, and control panel storage bin/trays.

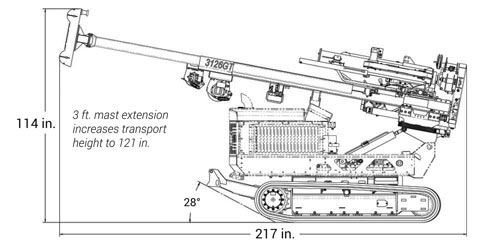

Pivoting Winch Mast Option

Pivoting winch mast lowers transportation height by 15 inches

The pivoting winch mast option for the 3126GT is designed for customers who prefer to haul their rig in an enclosed trailer or truck, lowering the transportation height by 15 inches.

"This reduces the transport height of the 3126GT from 114 inches to 99 inches," Ryan Kejr, machine engineer lead, said. "We accomplish this with a simple, mechanical ratcheting actuator. This is easily accessible from the ground when the drill mast is in transport position."

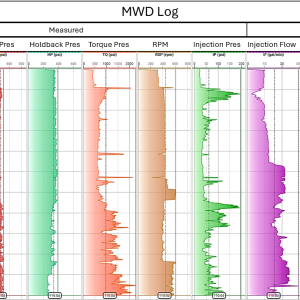

NEW Measurement While Drilling (MWD)

MWD

MWD (Measurement While Drilling) is a method of collecting digital data from the drill rig to log parameters pertaining to drilling operation. These methods are common in other parts of the world where it has been standard to log or measure drilling parameters in the oil, gas, and mining industries.

Starting in 2024, Geoprobe® 31 series geotechnical drill rigs are MWD capable. The option can be added at any time to include an MWD kit allowing drilling parameters to be recorded

- Common parameters for MWD are crowd force, torque, penetration rate, mud pump pressure, mud flow rate, holdback pressure, head rotation speed and hole depth.

- Follows ISO 22476-15 International Standard for MWD.

- All sensors utilized are common Geoprobe® components with proven experience and reliability.

- MWD sensors are easily integrated into existing rig electronics to maximize usefulness of sensor data being currently collected.

- Calibrated outputs are delivered to the data logger of your choice via J1939 CAN Bus network on the drill, simplifying the rig’s wiring.

Features & Options

Video: Geoprobe® Walkaround: The 3126GT Drill Rig

Owners praise their Geoprobe® 3126GT geotechnical drill for its simplicity and safety so new drillers quickly travel the learning curve. Veteran drillers appreciate the attention to features addressing their field needs. Together all the standard features and available options minimize operating costs and come in at a price point lower than you might anticipate.

- ENGINEERED FOR EFFICIENCY: with six functions along the centerline, use machine hydraulics and controls to side-shift the head, simplifying your geotech applications. Complete augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT — even direct push — without manipulating mast position or mobilizing multiple machines.

- ENHANCED EASE AND SAFETY: boost geotechnical drill output and utilization with hands-free automatic drop hammer and integrated CPT head-feed rate control, including cone overload protection. Leverage small footprint to expand site access without sacrificing flow from mud pump or accessory storage. Bring new drillers up the learning curve quickly with easy controls and integrated safety features built to internationally-accepted standards.

- ELEVATED SERVICE AND SUPPORT: respond to your clients needs, making a quick call to get answers to your field and geotechnical drill service questions with overnight part shipping available from industry-leading support team.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your geotechnical drill is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new geotechnical drill? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Six functions along the 28-inch centerline head side shift simplify traditional geotechnical applications — augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT – and even direct push. Features GH63 percussion hammer 4-speed rotary head with 4,000 ft-lb, DH104 hands-free automatic drop hammer, CPT push/pull assembly, and a rod grip pull system. Head shifting speeds up drilling and minimizes the time driller spends in danger zone.

With 170-lb, 300-lb, or 340-lb options, the hands-free automatic drop hammer reduces strain when driving SPT samples. Advance borings for SPT testing by augering, driven casing and sampling, or wash boring.

The winch mast telescopes into place, allowing for flexible height options based on work environment. This also adds a layer of safety during setup when working near overhead power lines or other obstacles.

Taller telescoping winch mast specifically designed for geotech work with heavier winch options, 105-inches head travel, and 36,000-lbf push and 48,000-lbf pull at the head-feed cylinder means greater pull back – ideal for drive and wash – and head travel. Allows tripping out of 20-foot lengths of rod when combined with 3-foot extension.

Align the probe cylinder and tool string on a straight – or angled – path to the subsurface while the machine remains stable with the built-in oscillation, standard on all machines.

Drill mast features extend, swing, mast dump, oscillation, and fold. Mast dump provides 36.5 inches of vertical travel to allow room for a mud pan. Optional outriggers available.

A dual winch option is typically configured with a 6,800-lbf winch for the more difficult pulling and an 1,800-lbf. with quick-change hook. When ready to switch from pulling to coring, simply swap out the swivel hook for the overshot clevis installed on your overshot and continue working. It’s quick, simple, and can all be done by hand.

Additional winch options include 2,500-lbf and 1,100-lbf.

Also available is a third winch with 1,100 lbs of line pull, well suited to trip additional tooling out of the hole. Equipped with the Geoprobe® exclusive quick change hook, operators can switch over to wireline coring in seconds.

While customers are proving the rock coring capabilities of the 4-speed rotary head on the 3126GT, some customers have requested more bottom-end torque for their geotech jobs. True to form, Geoprobe® responded by designing the 6-speed GR6.5 rotary head with 70 percent more torque.

"The GR6.5 has 6,800 ft-lbs of torque, which is 2,800 ft-lbs more than the GR4.1 on a typical 7822DT, without sacrificing top-end speed (720 rpm)," Ryan Kejr, machine engineer lead, said. "We also added an additional intermediate-speed range, which further enhances the unit's wet and air rotary capabilities."

Video: Geoprobe® 3126GT Mud Rotary Drilling

All functions are at your fingertips in a well-organized, compact control panel. The systems display provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Hands-free rotary and head feed controls on the 3126GT reduce strain on driller when completing applications like mud rotary. CPT feed rate and hydraulic limit functions are standard.

The 7-inch single breakout firmly grips casing with a clamp force of up to 21,000 pounds of force. The breakout can be positioned either under the hammer or the rotary drive, as well as swung away from the machine.

An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

The rear blade can be used for tool transport. During site setup, a tooling drop rack can be placed in front of the machine for easy access. This eliminates the need to walk around the machine for tooling, which saves time and conserves energy in the field.

Ample, well-spaced storage includes two stacked tool boxes, helper-side storage compartments, and control panel storage bin/trays.

The pivoting winch mast option for the 3126GT is designed for customers who prefer to haul their rig in an enclosed trailer or truck, lowering the transportation height by 15 inches.

"This reduces the transport height of the 3126GT from 114 inches to 99 inches," Ryan Kejr, machine engineer lead, said. "We accomplish this with a simple, mechanical ratcheting actuator. This is easily accessible from the ground when the drill mast is in transport position."

MWD (Measurement While Drilling) is a method of collecting digital data from the drill rig to log parameters pertaining to drilling operation. These methods are common in other parts of the world where it has been standard to log or measure drilling parameters in the oil, gas, and mining industries.

Starting in 2024, Geoprobe® 31 series geotechnical drill rigs are MWD capable. The option can be added at any time to include an MWD kit allowing drilling parameters to be recorded

- Common parameters for MWD are crowd force, torque, penetration rate, mud pump pressure, mud flow rate, holdback pressure, head rotation speed and hole depth.

- Follows ISO 22476-15 International Standard for MWD.

- All sensors utilized are common Geoprobe® components with proven experience and reliability.

- MWD sensors are easily integrated into existing rig electronics to maximize usefulness of sensor data being currently collected.

- Calibrated outputs are delivered to the data logger of your choice via J1939 CAN Bus network on the drill, simplifying the rig’s wiring.

The rig has a lot of push/pull capacity but also a lot of control. The hydraulic lever handles we're used to versus the display and ability to tune controls on the 3126GT control panel is way, way ahead of other drilling rigs. How Geoprobe® worked out the operating system impressed me more than anything. They took care of all the little details to make things easier in the field.

- Dave Harness, Project Manager, Alt & Witzig Engineering, Indiana

Tooling & Accessories

Video: Interlocking Split Spoon Overview

Engineered to be stronger, last longer, and save money and time, the patented interlocking split spoon meets ASTM Standard D1586.The finger-like design self aligns, creating a perfect fit and quicker assembly. With the threads aligned, the cutting shoe and drive head can be threaded to the split spoon. Multi-lead threads require fewer turns during assembly and disassembly over conventional split spoons, speeding up each test interval.In additional to time savings, enhanced material properties and manufacturing result in greater longevity. Each interlocking point keeps the two tube halves engaged throughout the sampling process. The strength of these connections prevents the sampler from bulging in dense materials. It also keeps the tube halves tightly engaged even when over-filling of the sampler occurs.

Video: Geoprobe® Spring Assisted Swivel Lift Cap

The Spring Assisted Swivel Lift Cap is designed to reduce operator fatigue when adding or removing sections of rods to the inner tool string. The internal springs of the pull cap bear the weight of the rod string. With minimal effort, the operator can adjust the rod string up or down when threading or unthreading the rods. The natural self-alignment of the rod string prevents tipping off center and binding of the threads.

Video: Geoprobe® Macro-Core® Center Rod

Our MC5 Soil Sampling System is a single tube, discrete or continuous system with unmatched durability.MC5 Light Weight Center Rod Soil Sampling System. The MC5 1.25-inch Center Rod System was designed for the absolute worst of the worst direct push probing conditions. “These are conditions that we normally do not recommend probing in,” according to Mike Carlin, Project Engineer, “so we developed the toughest soil sampling system in the direct push industry ... it’s a brute!”Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Video: DT22 Soil Sampling System Overview

The Geoprobe® DT22 Soil Sampling System is a direct push system for collecting continuous core samples of unconsolidated materials from within a sealed casing of Geoprobe® 2.25- inch outside diameter probe rods. Samples are collected and retrieved within a liner that is threaded onto the leading end of a string of Geoprobe® 1.25-inch OD light-weight center rods and are inserted to the bottom of the outer casing.

The DT37 Soil Sampling System, designed for use with 3.75-inch probe rods, uses a unique combination of the cutting shoe, sheath, and liner retainer to allow efficient recovery of samples in formations ranging from plastic clays to saturated sands. The DT37 system is designed to quickly recover samples well below the water table. Problems with liner failure or having the liner lodge in sample sheath are virtually eliminated with this system.

Video: SP22-ISP Groundwater Sampler

The Screen Point 22 (SP22) Groundwater Sampler from Geoprobe Systems® was designed to keep the screen away from all percussive energy while the sampler is lowered downhole, thus extending the life of the screen.The SP22 can be used alone as a groundwater grab sampler or groundwater profiling tool, or with the DT22 Soil Sampling System. The screens can be deployed using either 1.25-inch Lightweight Center Rods or PVC riser.Designed for tough probing conditions, the screen head on the fully retrievable sampler adapts to either a stainless steel or PVC screen.

Applications

Videos

MWD - Measurement While Drilling

ID: 14039

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

Geoprobe® 3126GT Head Side-Shift

ID: 1903

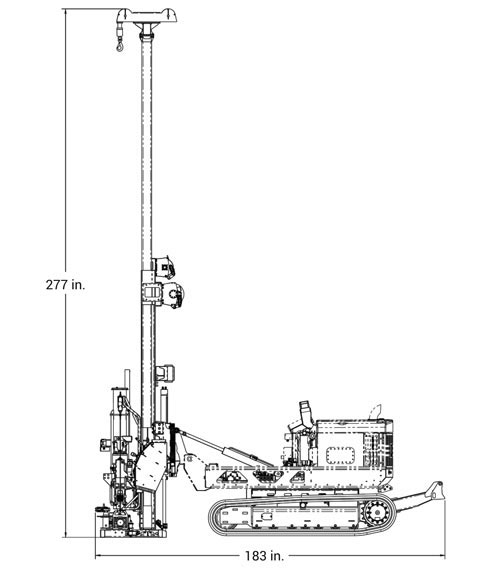

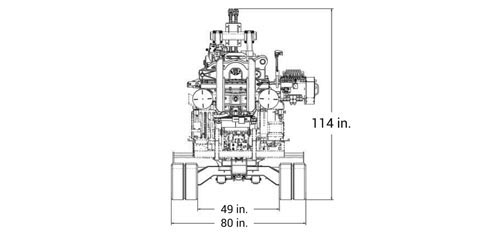

Specs

Specifications are subject to change without notice.

| Standard | Metric | |||

|---|---|---|---|---|

| Overall Dimensions | units | units | ||

| Width | in | 80 | mm | 2032 |

| Length (transport) | in | 214 | mm | 5436 |

| Length (deployed, lateral fully extended) | in | 175 | mm | 4445 |

| Height (normal transport) | in | 114 | mm | 2896 |

| Height (transport -- folding winch mast option) | in | 99 | mm | 2515 |

| Height (deployed; winch mast up) | in | 277 | mm | 7036 |

| Approach/departure angle in transport | degrees | degrees | ||

| Base Unit Weight | lbs | TBD | kg | TBD |

| Unit Weight (w/ typical options) | lbs | 12600 | kg | 5715 |

| Ground Speed | mph | 2.5 | kmh | 4.0 |

| Estimated Track Surface Area | in2 | 1958.0 | ||

| Estimated Ground Pressure (base unit) | psi | bar | ||

| Estimated Ground Pressure (w/ typical options) | psi | 6.4 | bar | 0.4 |

| Drill Mast Positioning | ||||

| Extension (fore and aft) | in | 15 | mm | 381 |

| Lateral (side to side) | ± degrees | 7 | ± degrees | 7 |

| Oscillation | degrees | 10 | degrees | 10 |

| Drill Mast Dump | in | 36.5 | mm | 927 |

| Drill end outrigger travel | in | 16 | mm | 406 |

| Rear stabilizer travel (Engine end) | in | 26 | mm | 660 |

| Rear stabilizer width | in | 60 | mm | 1524 |

| Rear stabilizer lift | lbs | 2000 | kN | 2000 |

| Max angle drilling ability off vertical | degrees | degrees | ||

| Drill Mast Specifications | ||||

| Head Travel | in | 105 | mm | 2667 |

| Head Crowd Force | lbs | 36,000 | kN | 160 |

| Head Pull Force | lbs | 48,000 | kN | 214 |

| Head Feed Rate Down | fpm | 27.1 | m/min | 8.25 |

| Head Feed Rate Up (regen) | fpm | 71.9 | m/min | 21.92 |

| Head Feed Rate Up (non-regen) | fpm | 24.2 | m/min | 7.37 |

| Head Feed Carriage | Comp. slides | Comp. slides | ||

| Head Feed Pressure Control | Optional | Optional | ||

| Head Rate Control | Standard | Standard | ||

| Head Sideshift | in | 28 | mm | 711 |

| Prime Mover & Hydraulic Specs | ||||

| Engine | Kubota V2403 T4/Stage V | Kubota V2403 T4/Stage V | ||

| Engine Rated Power | hp | 65 | kW | 48 |

| Fuel Capacity | gal | 17 | L | 64 |

| Pump type | type | Axial Piston -LS/HP Limited | type | Axial Piston -LS/HP Limited |

| Max pressure | psi | 4,000 | bar | 276 |

| Max flow | gpm | 40 | L/min | 151 |

| Additional Pump | Pump | Hydrostat (mud pump) | Pump | Hydrostat (mud pump) |

| Max pressure | psi | 4000 | bar | 276 |

| Max flow | gpm | 18 | L/min | 68 |

| Direct Push Hammer | ||||

| GH6400 | GH6400 | |||

| Rotary Drive Options | ||||

| GR4.1 | GR4.1 | |||

| Type | 2 Spd Hyd+2 Spd Mech | 2 Spd Hyd+2 Spd Mech | ||

| Range 1 Torque | ft-lbs | 4000 | N-m | 5423 |

| Highest Range Speed | rpm | 750 | rpm | 750 |

| Swivel Type | Side | Side | ||

| GR6.5 | GR6.5 | |||

| Type | 3 Spd Hyd+2 Spd Mech | 3 Spd Hyd+2 Spd Mech | ||

| Range 1 Torque | ft-lbs | 6800 | N-m | 9220 |

| Highest Range Speed | rpm | 720 | rpm | 720 |

| Swivel Type | Side | Side | ||

| Standard Winch (Position 1) | ||||

| line pull | lbf | 6800 | kN | 30.25 |

| line speed | fpm | 130 | m/min | 39.6 |

| cable length | ft | 75 | m | 22.9 |

| Second Winch (Position 2) | ||||

| line pull | lbf | 2500 | kN | 11.12 |

| line speed | fpm | 125 | m/min | 38.1 |

| cable length | ft | 75 | m | 22.9 |

| line pull | lbf | 1800 | kN | 8.01 |

| line speed | fpm | 125 | m/min | 38.1 |

| cable length | ft | 175 | m | 53.4 |

| line pull | lbf | 1100 | kN | 4.89 |

| line speed | fpm | 230 | m/min | 70.1 |

| cable length | ft | 250 | m | 76.3 |

| Third Winch (Position 3) | ||||

| line pull | lbf | 1100 | kN | 4.89 |

| line speed | fpm | 230 | m/min | 70.1 |

| cable length | ft | 250 | m | 76.3 |

| Auto Drop Hammer | ||||

| Drop height | in | 30 | mm | 762 |

| Float | in | 31 | mm | 787 |

| Breakout | ||||

| Single Clamp | ||||

| Max Clamp force | lbf | 21,000 | kN | 93 |

| Breakout torque | ft-lb | 6,000 | N-m | 8135 |

| Min Casing size compatible | in | 1.25 | mm | 31.75 |

| Max Casing size compatible | in | 6 | mm | 152.4 |

| Vertical travel | in | NA | mm | NA |

| Mud Pump Options | ||||

| 2L4 | 2L4 | |||

| 3L6 | 3L6 | |||

| SPX40 | SPX40 | |||

| Triplex | Triplex | |||

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Standard | Metric | |||

|---|---|---|---|---|

| Overall Dimensions | units | units | ||

| Width | in | 80 | mm | 2032 |

| Length (transport) | in | 214 | mm | 5436 |

| Length (deployed, lateral fully extended) | in | 175 | mm | 4445 |

| Height (normal transport) | in | 114 | mm | 2896 |

| Height (transport -- folding winch mast option) | in | 99 | mm | 2515 |

| Height (deployed; winch mast up) | in | 277 | mm | 7036 |

| Approach/departure angle in transport | degrees | degrees | ||

| Base Unit Weight | lbs | TBD | kg | TBD |

| Unit Weight (w/ typical options) | lbs | 12600 | kg | 5715 |

| Ground Speed | mph | 2.5 | kmh | 4.0 |

| Estimated Track Surface Area | in2 | 1958.0 | ||

| Estimated Ground Pressure (base unit) | psi | bar | ||

| Estimated Ground Pressure (w/ typical options) | psi | 6.4 | bar | 0.4 |

| Drill Mast Positioning | ||||

| Extension (fore and aft) | in | 15 | mm | 381 |

| Lateral (side to side) | ± degrees | 7 | ± degrees | 7 |

| Oscillation | degrees | 10 | degrees | 10 |

| Drill Mast Dump | in | 36.5 | mm | 927 |

| Drill end outrigger travel | in | 16 | mm | 406 |

| Rear stabilizer travel (Engine end) | in | 26 | mm | 660 |

| Rear stabilizer width | in | 60 | mm | 1524 |

| Rear stabilizer lift | lbs | 2000 | kN | 2000 |

| Max angle drilling ability off vertical | degrees | degrees | ||

| Drill Mast Specifications | ||||

| Head Travel | in | 105 | mm | 2667 |

| Head Crowd Force | lbs | 36,000 | kN | 160 |

| Head Pull Force | lbs | 48,000 | kN | 214 |

| Head Feed Rate Down | fpm | 27.1 | m/min | 8.25 |

| Head Feed Rate Up (regen) | fpm | 71.9 | m/min | 21.92 |

| Head Feed Rate Up (non-regen) | fpm | 24.2 | m/min | 7.37 |

| Head Feed Carriage | Comp. slides | Comp. slides | ||

| Head Feed Pressure Control | Optional | Optional | ||

| Head Rate Control | Standard | Standard | ||

| Head Sideshift | in | 28 | mm | 711 |

| Prime Mover & Hydraulic Specs | ||||

| Engine | Kubota V2403 T4/Stage V | Kubota V2403 T4/Stage V | ||

| Engine Rated Power | hp | 65 | kW | 48 |

| Fuel Capacity | gal | 17 | L | 64 |

| Pump type | type | Axial Piston -LS/HP Limited | type | Axial Piston -LS/HP Limited |

| Max pressure | psi | 4,000 | bar | 276 |

| Max flow | gpm | 40 | L/min | 151 |

| Additional Pump | Pump | Hydrostat (mud pump) | Pump | Hydrostat (mud pump) |

| Max pressure | psi | 4000 | bar | 276 |

| Max flow | gpm | 18 | L/min | 68 |

| Direct Push Hammer | ||||

| GH6400 | GH6400 | |||

| Rotary Drive Options | ||||

| GR4.1 | GR4.1 | |||

| Type | 2 Spd Hyd+2 Spd Mech | 2 Spd Hyd+2 Spd Mech | ||

| Range 1 Torque | ft-lbs | 4000 | N-m | 5423 |

| Highest Range Speed | rpm | 750 | rpm | 750 |

| Swivel Type | Side | Side | ||

| GR6.5 | GR6.5 | |||

| Type | 3 Spd Hyd+2 Spd Mech | 3 Spd Hyd+2 Spd Mech | ||

| Range 1 Torque | ft-lbs | 6800 | N-m | 9220 |

| Highest Range Speed | rpm | 720 | rpm | 720 |

| Swivel Type | Side | Side | ||

| Standard Winch (Position 1) | ||||

| line pull | lbf | 6800 | kN | 30.25 |

| line speed | fpm | 130 | m/min | 39.6 |

| cable length | ft | 75 | m | 22.9 |

| Second Winch (Position 2) | ||||

| line pull | lbf | 2500 | kN | 11.12 |

| line speed | fpm | 125 | m/min | 38.1 |

| cable length | ft | 75 | m | 22.9 |

| line pull | lbf | 1800 | kN | 8.01 |

| line speed | fpm | 125 | m/min | 38.1 |

| cable length | ft | 175 | m | 53.4 |

| line pull | lbf | 1100 | kN | 4.89 |

| line speed | fpm | 230 | m/min | 70.1 |

| cable length | ft | 250 | m | 76.3 |

| Third Winch (Position 3) | ||||

| line pull | lbf | 1100 | kN | 4.89 |

| line speed | fpm | 230 | m/min | 70.1 |

| cable length | ft | 250 | m | 76.3 |

| Auto Drop Hammer | ||||

| Drop height | in | 30 | mm | 762 |

| Float | in | 31 | mm | 787 |

| Breakout | ||||

| Single Clamp | ||||

| Max Clamp force | lbf | 21,000 | kN | 93 |

| Breakout torque | ft-lb | 6,000 | N-m | 8135 |

| Min Casing size compatible | in | 1.25 | mm | 31.75 |

| Max Casing size compatible | in | 6 | mm | 152.4 |

| Vertical travel | in | NA | mm | NA |

| Mud Pump Options | ||||

| 2L4 | 2L4 | |||

| 3L6 | 3L6 | |||

| SPX40 | SPX40 | |||

| Triplex | Triplex | |||

Operator Side - Unfolded

Helper Side - Folded

Front - Folded

Resources

Click on a section below to view information.

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Adjusting mast dump to position control panel and using blade to optimize drop rack positioning make the workspace more comfortable.

ID: 14600 | Date:

3126GT versatility satisfies clients seeking multiple sampling methods, all with a single rig, while smaller footprint simplifies mobilization.

ID: 14353 | Date:

The ability to mobilize tools on drop rack and efficiently set up for boring positioned 3126GT for success on project requiring crane lift over wall.

ID: 14009 | Date:

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.