Hydraulic System Check-up

Checking Fluid Levels on 54LT machine

Darren Stanley, Geoprobe® Service Manager offers a few suggestions for all machine owners to keep the hydraulic system in top shape.

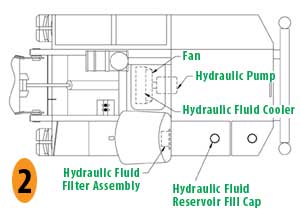

- Check the hydraulic fluid level at the beginning of each work day while the machine is completely folded and the fluid is cool. The fluid level fluctuates when the unit is folded versus unfolded as the fluid moves from the hydraulic tank to the individual cylinders. Hydraulic fluid also expands as it heats, so it’s important to allow for fluid expansion in the tank without overflowing.The proper hydraulic fluid level is important to the hydraulics system in your Geoprobe® machine. Check the hydraulic fluid level by looking at the sight glass on the side of the hydraulic tank (a Geoprobe® Model 54LT is shown), or on some units, by checking the dipstick on the hydraulic cap. Check your Owner’s Manual for the correct fluid levels.

- Check the hydraulic fluid cooler daily to keep it free of dirt and debris that may prevent it from getting clean air. Darren suggests rinsing the hydraulic cooler frequently to prevent hidden dirt from building up between the fins on the cooler (do not use power washers). Each machine has a different cooler location. Refer to your Owner’s Manual for specific hydraulic cooler locations.

- Change the hydraulic fluid and filter ... before it’s too late! As your machine runs, the hydraulic fluid breaks down and looses its ability to lubricate the hydraulics system properly. It can also become contaminated with dirt and debris causing the hydraulic filter to plug and restrict flow. Result: your unit overheats. Broken down fluid, dirt and debris, as well as running your machine at high temperatures, prematurely wears the unit’s pump, manifold, valve body, as well as seals and O-rings. Follow the service schedule in your Owner’s Manual, and when in doubt, service your unit before you get too busy to take care of it at the scheduled time!

Geoprobe® brand probing machines now use Mobilfluid 424 (P/N RP53131) for the hydraulic systems which should be easier for probe owners to buy locally. Mobil motor oil, 15W-40 (P/N 5976), is now used in Kubota engines in track-mounted units and for the power packs in stand-alone machines.

Darren Stanley, Geoprobe® Service Manager offers a few suggestions for all machine owners to keep the hydraulic system in top shape.

- Check the hydraulic fluid level at the beginning of each work day while the machine is completely folded and the fluid is cool. The fluid level fluctuates when the unit is folded versus unfolded as the fluid moves from the hydraulic tank to the individual cylinders. Hydraulic fluid also expands as it heats, so it’s important to allow for fluid expansion in the tank without overflowing.The proper hydraulic fluid level is important to the hydraulics system in your Geoprobe® machine. Check the hydraulic fluid level by looking at the sight glass on the side of the hydraulic tank (a Geoprobe® Model 54LT is shown), or on some units, by checking the dipstick on the hydraulic cap. Check your Owner’s Manual for the correct fluid levels.

- Check the hydraulic fluid cooler daily to keep it free of dirt and debris that may prevent it from getting clean air. Darren suggests rinsing the hydraulic cooler frequently to prevent hidden dirt from building up between the fins on the cooler (do not use power washers). Each machine has a different cooler location. Refer to your Owner’s Manual for specific hydraulic cooler locations.

- Change the hydraulic fluid and filter ... before it’s too late! As your machine runs, the hydraulic fluid breaks down and looses its ability to lubricate the hydraulics system properly. It can also become contaminated with dirt and debris causing the hydraulic filter to plug and restrict flow. Result: your unit overheats. Broken down fluid, dirt and debris, as well as running your machine at high temperatures, prematurely wears the unit’s pump, manifold, valve body, as well as seals and O-rings. Follow the service schedule in your Owner’s Manual, and when in doubt, service your unit before you get too busy to take care of it at the scheduled time!

Geoprobe® brand probing machines now use Mobilfluid 424 (P/N RP53131) for the hydraulic systems which should be easier for probe owners to buy locally. Mobil motor oil, 15W-40 (P/N 5976), is now used in Kubota engines in track-mounted units and for the power packs in stand-alone machines.

Service Knowledgebase Index

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Service Locations

Kansas Service Center - Salina, KS

1835 Wall Street • Salina, Kansas 67401

785-825-1842Just one mile west of I-135 and an hour and half north of Wichita or two and half hours west of Kansas City, the drill rig service team keeps customers in the field through telephone service support or in shop repairs.

Southeast Service Center - Ocala, FL

5801 SW 6th Place • Ocala, Florida 34474

352-854-1566Just one mile west of I-75 and an hour northwest of Orlando, drillers have come to rely on the drill rig service team with double-digit years of hands-on experience servicing any rig for helpful answers or intensive rig fixes.

East Coast Service Center - Oxford, PA

468 Limestone Rd • Oxford, PA 19363

610-467-1750Just 30 minutes off of I-95, an hour west of Philadelphia, and two hours southwest of Newark, New Jersey. Rely on our team for refurbishments, repairs, and aftermarket upgrades for any rig.

North Carolina Service Center - Hickory, NC

2515 US Highway 70 SW • Hickory, NC 28602

828-998-0977Just 5 minutes off I-40 and an hour northwest of Charlotte, the drill rig service team provides support ranging from routine maintenance to intensive repairs for any rig.