SRC30DT

Video: Geoprobe® Walkaround: SRC30DT Sonic Rod Carrier

Virtually Hands-Free Sonic Drilling

Simplify sonic drilling using self-propelled sonic rod carrier with dual quick-attach 10-foot rod magazines. Save time using independent rod magazines capable of being removed with a forklift. Front and rear outriggers designed with +/-7 inches of side shift allow for easy alignment with the 8150LS sonic drilling rig.

- Achieve virtually hands-free sonic drilling operation when paired with the optional 8150LS sonic drilling rig rod handling system.

- Carry combination of sonic drill rod magazines containing up to 300 feet of 3.5-inch, 250 feet of 4.5-inch, or 200 feet of 6-inch OD sonic drill rod with ability to feed additional rods from rear of carrier.

After positioning on site, hydraulically tether to 8150LS for power during site operation. Use the swing arm control panel positions for helper or driller to manage tooling and pass through design permits loading additional rods from rear of carrier when needed.

Specs

Specifications are subject to change without notice.

| Overall Dimensions (Standard) | Overall Dimensions (Metric) | ||

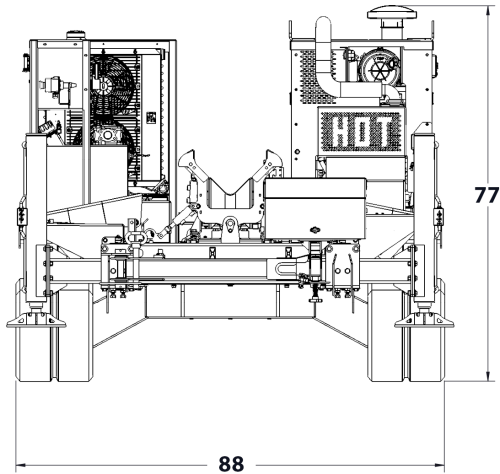

| Width (in) | 88 | Width (mm) | 2,235 |

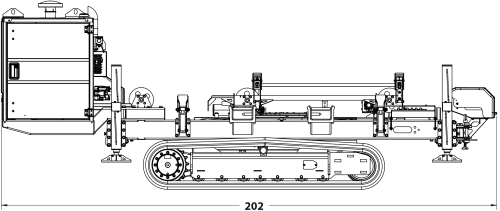

| Length (transport) (in) | 202 | Length (transport) (mm) | 5,131 |

| Height (normal transport) (in) | 77 | Height (normal transport) (mm) | 1,956 |

| Base Unit Weight (No Tooling) (lbs) | 8,900 | Base Unit Weight (No Tooling) (kg) | 4,037 |

| Ground Speed (mph) | 2.7 | Ground Speed (kph) | 4.35 |

| Estimated Track Surface Area (in2) | 1,958 | Estimated Track Surface Area (cm2) | 2896 |

| Estimated Ground Pressure (psi) | 4.55 | Estimated Ground Pressure (bar) | 0.31 |

| Outrigger Positioning | Outrigger Positioning | ||

| Outrigger travel past ground (in) | 15 | Outrigger travel past ground (mm) | 381 |

| Outrigger travel Left/Right (in) | +/-4 | Outrigger travel Left/Right (mm) | 101.6 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota® V2403T Tier 4/Stage 5 | Engine | Kubota® V2403T Tier 4/Stage 5 |

| Engine Rated Power (hp) | 56 | Engine Rated Power (kW) | 42 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump Type | Axial Piston - LS-HP limited | Pump Type | Axial Piston - LS-HP limited |

| Max Pressure (psi) | 3,400 | Max Pressure (bar) | 234.4 |

| Max Flow (gpm) | 40 | Max Flow (L/min) | 151 |

| Additional Pump | NA | Additional Pump | NA |

| Safety | |||

| Max Allowable Surface Slope for Transport Condition(1) | 20° | ||

(1) Max allowable surface slopes are for the base machine configuration. Additional options or tooling loads can significantly alter stability.

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions (Standard) | Overall Dimensions (Metric) | ||

| Width (in) | 88 | Width (mm) | 2,235 |

| Length (transport) (in) | 202 | Length (transport) (mm) | 5,131 |

| Height (normal transport) (in) | 77 | Height (normal transport) (mm) | 1,956 |

| Base Unit Weight (No Tooling) (lbs) | 8,900 | Base Unit Weight (No Tooling) (kg) | 4,037 |

| Ground Speed (mph) | 2.7 | Ground Speed (kph) | 4.35 |

| Estimated Track Surface Area (in2) | 1,958 | Estimated Track Surface Area (cm2) | 2896 |

| Estimated Ground Pressure (psi) | 4.55 | Estimated Ground Pressure (bar) | 0.31 |

| Outrigger Positioning | Outrigger Positioning | ||

| Outrigger travel past ground (in) | 15 | Outrigger travel past ground (mm) | 381 |

| Outrigger travel Left/Right (in) | +/-4 | Outrigger travel Left/Right (mm) | 101.6 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota® V2403T Tier 4/Stage 5 | Engine | Kubota® V2403T Tier 4/Stage 5 |

| Engine Rated Power (hp) | 56 | Engine Rated Power (kW) | 42 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump Type | Axial Piston - LS-HP limited | Pump Type | Axial Piston - LS-HP limited |

| Max Pressure (psi) | 3,400 | Max Pressure (bar) | 234.4 |

| Max Flow (gpm) | 40 | Max Flow (L/min) | 151 |

| Additional Pump | NA | Additional Pump | NA |

| Safety | |||

| Max Allowable Surface Slope for Transport Condition(1) | 20° | ||

(1) Max allowable surface slopes are for the base machine configuration. Additional options or tooling loads can significantly alter stability.

Front View

Right View

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.