7822DT geotechnical investigation

Establishing a strong foothold in the direct push business, Geo Lab Drilling got their start in 1996 as a sampling and on-site lab screening company, using a van-mounted probe and mobile chemistry lab. Growth of the company allowed them to progress from solely a direct push investigation firm into a more long-term monitoring and remediation focus. The addition of a 66DT with auger head opened up more horizons, but required some re-education of consultants to teach them that Geoprobe® doesn’t mean just direct-push.

“Yes, we’re going to install hollow stem augered wells, and yes, we’re going to do it with a Geoprobe®,” Brian Strickland, owner, said. “Environmental services require more than just direct push.”

Over the years they’ve continued to look for ways to stretch their capabilities.

“We also purchased conventional drill rigs to broaden our scope of services beyond direct push, only to realize that 7822DT rigs are often preferred for conventional rotary drilling tasks due to their efficiency and mobility,” Strickland said.

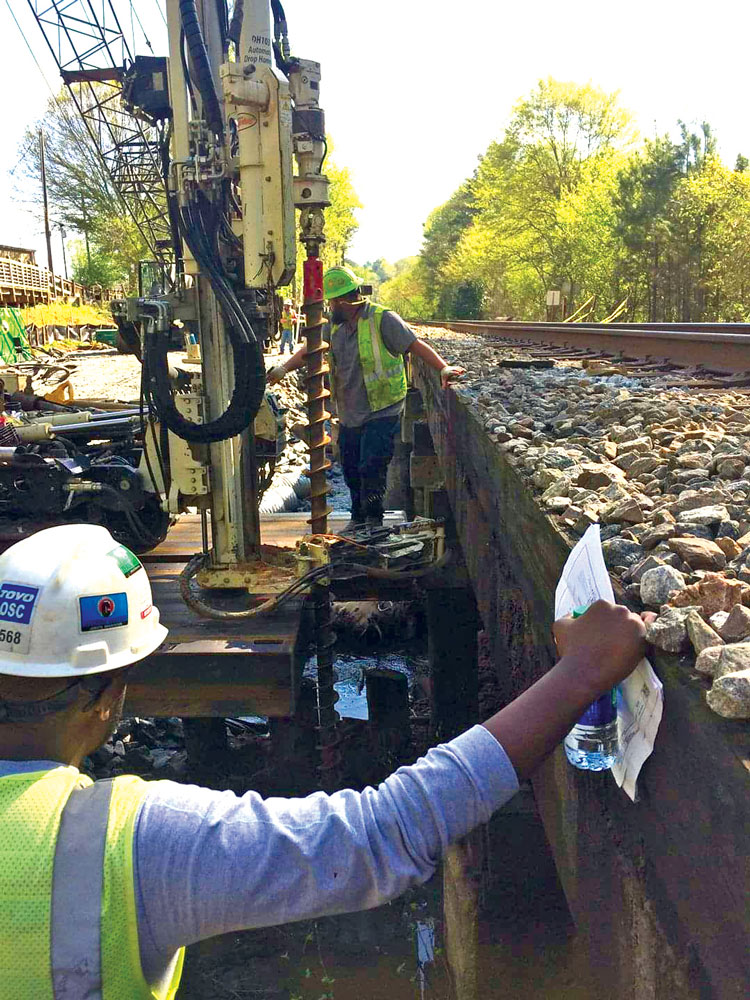

Rock Coring

In the piedmont of the South, they’re penetrating shallow rock with a downhole air hammer using a large air compressor and a 7822DT. The height of the drillmast accommodates 5-foot rods and an air swivel to feed the air hammer. With the addition of the 4-speed head, they’re now performing mud rotary and NQ wireline rock coring. Active development in Georgia keeps them busy completing geotechnical investigations which often involve shallow SPT borings to rock with an automatic drop hammer, and then quick conversion to NQ wireline coring for 10 to 15 feet of rock core confirmation.

“The 7822DT is very efficient and often outperforms conventional rigs head-to-head. Its agility allows us to complete 80 to 100 feet of rock coring in a day,” Strickland said. “In a playground dominated by conventional drill rigs, we can come in and show them that Geoprobe® rigs core rock well. The efficiency gained allows us to do more linear footage and play ball with the big dogs, and we don’t have to concede on rates or production.”

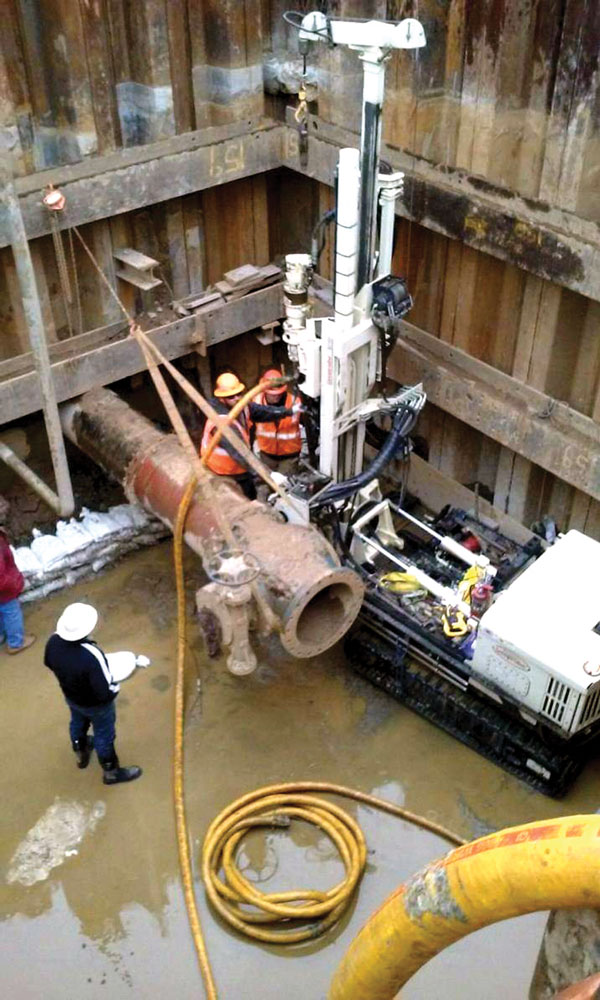

Limited Access

The 7822DT's tracks and small size also allows them to stretch into new spaces – off-road, inside buildings, and under canopies. Work on an Electrical Resistance Heading (ERH) remediation project required drilling and installing supplemental electrodes in and around previously installed electrodes and careful navigation around a mass network of electrical lines.

“No other rig could get into the nooks and crannies and creep over wires without damaging them,” Strickland said. “Where others have tried and failed, we succeed.”

They can successfully complete projects that require installing monitoring wells under gas station canopies or foraging through marshland while crossing small creeks to access remote sampling locations.

“Most conventional rigs can’t perform low-clearance work under canopies and inside buildings with the nimbleness of a 7822DT,” Strickland said. “We have the ability to respond across the board. Name the project and we have a distinct advantage if we can find the unique tool to do it. We know we have the rigs and the operators, which gives us more access and impresses customers.”

Quality Tooling

When they use Geoprobe® tooling they're confident they have the right tool.

“We mobilized to an out-of-state site where another drilling firm – who wasn’t using Geoprobe® rods – was consistently breaking off at 60 feet. The client was concerned we would encounter the same problem,” Strickland said. “Using genuine Geoprobe® rods, we repeatedly advanced to 90 feet over the entire project with no broken rods. Geoprobe® tooling quality is unparalleled.”

Success

“High utilization of our 7822DT rigs is due in part because they are requested by our clients both verbally and written into RFP’s," indicating to Strickland a strong return on his investment. He now can charge for more profitable applications like rock coring and the dependability of the 7822DT provides additional profit assurance.

“I’ve experienced more frequent mechanical failure of conventional rigs in our fleet. Geoprobe® is reliable to do a project and do it well,” Strickland said. “They’re reliable to go day in and day out. Bearings and general wear items seem to last much longer. They have a lower maintenance side and increased longevity.”

Geo Lab tries to stay on top of preventative maintenance schedules to avoid costly breakdowns, but when issues arise, they know they can rely on Geoprobe® service technicians for answers.

“A huge part of our success is our ability to get support when needed. You can clearly see a partnership, receiving support with a smile and lots of late hours, shipping at the 11th hour when necessary,” Strickland said. “Top knowledge and willingness to help is what differentiates Geoprobe® .”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date:

7822DT’s power and versatility excel at pushing cones and handling diverse geotechnical tasks like here at a Nike facility in Beaverton, Oregon.

ID: 14606 | Date:

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date: