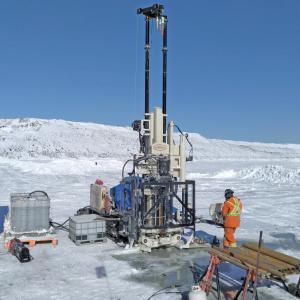

3230DT levees

Members of the dams and levees specialty division of GFA International are no strangers to the pressure for perfection. GFA's contract with the U.S. Army Corps of Engineers for work on the Herbert Hoover Dike, the largest Army Corps project in the nation, requires a 90 percent recovery rate. To be successful requires them to be efficient – and delicate.

“It’s a funny thing to say, but the drilling we’re doing is very delicate,” Tom Ortner, manager, said. “A whole day’s worth of work can be destroyed by applying too much down force.”

To remediate piping – water flowing out from under the dike, grabbing sand, causing the dike to erode or sinkholes to develop – in the seepage control project, the Army Corps has installed a cutoff wall along the southeast part of the dike that surrounds Lake Okeechobee. Cement and bentonite are mixed with the soil, making it cohesive, to form the 3-foot-thick wall. GFA’s role is to come through and core the new wall – perfectly straight through – up to 80 feet to test the cores and boreholes.

When they began working on the project they would mobilize one rig, conducting exploratory SPT to define a certain layer of the material. Then they would mobilize a second rig, conducting the coring of the very fragile 150-psi material. Their proficiency being gentle was paramount as they investigated ways to increase efficiency running the PQ3 wireline system. GFA found the perfect combination of precision and power with the Geoprobe® 3230DT.

“Often times in a top-head driven rig with multiple systems on top, it wobbles or has slack. In the type of work we’re doing we can’t have rigs that move around, we have to have them be true and straight and rigid,” Ortner said. “We have found the 3230DT to be very tight. No wobble.”

GFA also got the added benefit of increasing their productivity through the 3230DT’s direct push capabilities.

“Now we’re able to use the DT325 system and complete exploration almost twice as fast versus sending two different rigs to do the work,” Ortner said.

For Ortner, going from 80-100 feet of SPT per day to 180 feet of direct push has meant money in the bank.

“Our ability to direct push allows us to maximize footage. When we invoice, live, and breathe on rate-per-foot, the revenue increases on a daily basis make this a profitable service line,” Ortner said.

As a company GFA has always been open to change, moving away from older-style drill rigs to embrace technology and focus on what it can do for them. Perhaps unexpectedly, the 3230DT has expedited the training of new drillers, quickly turning them into more productive members of the team.

Prior to the 3230DT, the driller would establish a standard amount of time spent drilling required to reach the desired material. However, this wasn’t always a true test since the formation composition fluctuates.

“The sensitivity of the feed rate and weight on bit controls on the 3230DT allow you to see on the control panel what a 30-year-experienced driller knows,” Ortner said. “Now we can teach a guy the optimal weight on bit using the controls – so they know not to exceed a certain value – and a new driller can have confidence in completing the coring without damaging the material.”

For them, embracing technology also leads to safer operation. The double breakout on the 3230DT eliminates manually breaking connections often necessary on small rig platforms, minimizing opportunities to get hurt. The quick-connect hooks ease transition and encourage use of the correct tool versus avoiding harder to change hooks on other rigs.

Ultimately, adding the 3230DT to their fleet has added more work, which recently led them to add a new 3230DT.

“Our success rate since we started using the 3230DT has improved and opened doors on other projects. Contractors that we work for now want us to go wherever they go,” Ortner said. “We’re starting a new job in Illinois as a direct result of the work we’ve done on the Florida projects.”

In fact, the last four or five rigs GFA has purchased have been Geoprobe® as a result of Team Geoprobe®'s efforts to better the industry.

“When we bought our first 7822DT, we came and visited headquarters and were impressed with how Geoprobe® was wanting to change the industry, to make it better for the drillers,” Ortner said. “I like that they’re looking out for our interests, to help us become more efficient.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220