OIP-UVR (UV range) provides added confidence when detecting lighter-end jet fuels.

New Jersey-based S2C2 started as a mobile lab/direct-push company providing high resolution site characterization (HRSC) services in 1998. At that time, this was accomplished by collecting at depth discrete soil or groundwater samples and analyzing them on-site.

“We’ve been providing HRSC services since 1998, completing direct sensing projects throughout the United States and direct-push drilling primarily in the mid-Atlantic,” Jason Ruf, geologist, said. “We purchased our first direct sensing system in 2006. As direct sensing became our dominant offering, our mobile lab went away.”

Today S2C2 has three Membrane Interface Probe (MIP) systems along with two Hydraulic Profiling Tool (HPT) and one Optical Image Profiler Hydraulic Profiling Tool (OIHPT) systems.

On a recent project at Pease Air Force Base in Portsmouth, New Hampshire, S2C2 teamed with A-Zone Environmental Services to assist their client in a re-baselining of site conditions throughout the entire facility. Their client initially requested MIP logging to assist with the delineation of dissolved phase, fuel related impacts.

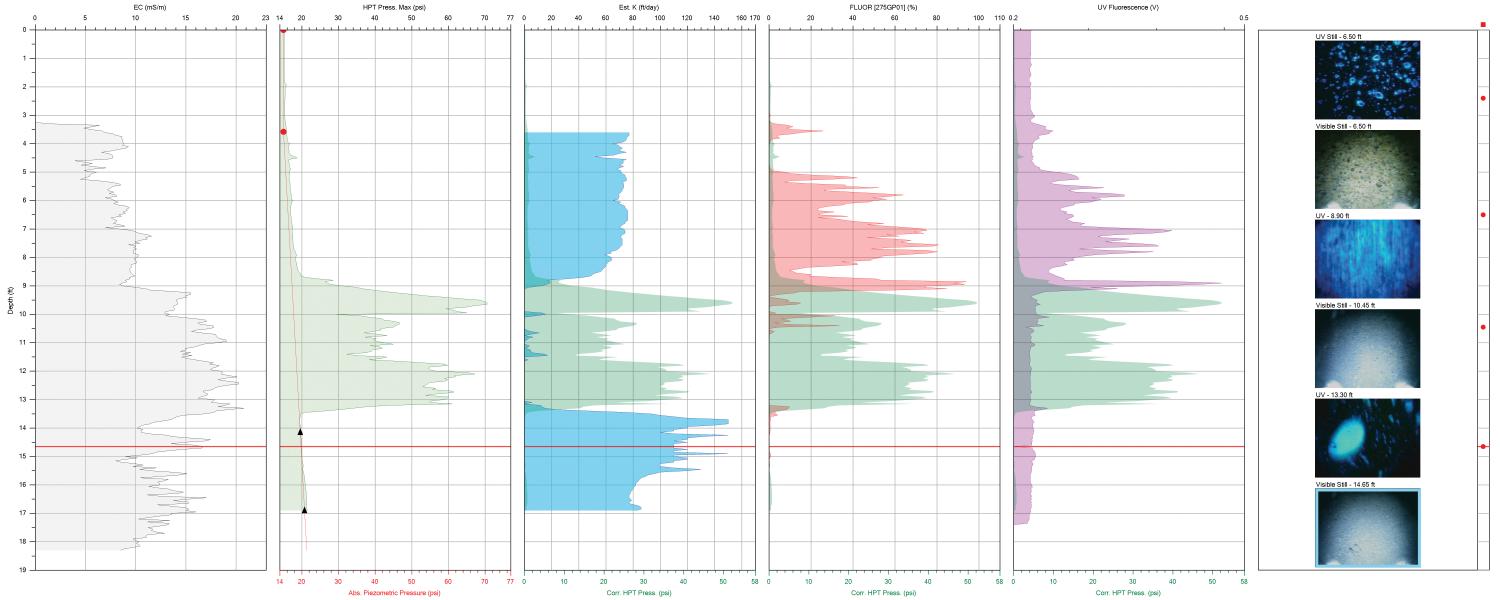

“As we were talking, it became clear that jet fuel was the primary contaminant of concern, so we steered them toward OIP, " Ruf said. “While talking with Dan Pipp [Geoprobe® chemist] about the project he suggested beta testing the Geoprobe® OIHPT-UVR probe, which can detect fluorescence in both the visible and UV spectrum, allowing for better detection of the light end components of jet fuels. We convinced the client that MIP could/and did have significant baseline issues if advanced through NAPL, so OIP turned out to be the primary tool utilized for the investigation and having the UVR was an added benefit.”

The project scope included completing 282 borings across eight different sites with 90 percent of the borings now slated for OIP. Borings were completed along flightlines and other areas of concern. A subset of borings were completed using the latest OIP-UVR (UV range).

“OIP technology is the go-to tool if looking for residual or free-phase NAPL,” Ruf said. "If it's a site where it’s possible we’ll encounter NAPL, we suggest to our clients to run OIP prior to MIP.”

Their goal is to delineate free and residual product and then go after the dissolved phase plume. The benefit of utilizing direct-sensing tools is having accurate high-resolution data of both geology and contaminants which is critical for any successful remediation design.

“The UVR gave us additional comfort knowing we could have a higher likelihood of detecting jet fuels,” Ruf said. “UV is the dominant tool for most petroleum sites since diesel and gasoline are the primary contaminants of concern. UVR is a good option when you know you have lighter-end NAPLs like jet fuel that are fluorescing in the lower wavelengths and that may not respond as well on the standard UV tool.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date:

7822DT’s power and versatility excel at pushing cones and handling diverse geotechnical tasks like here at a Nike facility in Beaverton, Oregon.

ID: 14606 | Date:

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date: