New electric actuator expedites collecting groundwater samples, eliminating doing sampling by hand.

Focused on environmental and geotechnical drilling since inception in 2017, Bulldog Drilling was on the hunt for a new probe rig to handle their jobs, which increasingly were more unique and "out of the box."

“We needed to replace an older probe rig and considered the 7822DT, the 3126GT — which we thought was too big, and the 6011DT — which we felt was too small,” Jennifer Scharringhausen, president, said. “The 7822DT could do all our environmental drilling and do our small geotech jobs in tight spaces.”

For driller Josh Edwards, rig amenities simplify his work.

“It’s made my job a lot easier to do overall. The hammer is efficient and powerful. The winch line and side table with clamp are handy when dual tubing. It’s much easier to take off the breakout clamp and auto hammer,” Edwards said. “The breakout clamp is pretty handy for keeping the rods from falling back down the hole when tripping out.”

Edwards appreciates convenience of the blade to transport a rod rack into the ideal position relative to the operator.

“You can drop the rack in front of the hole so rods are right next to you, and you don’t have to walk around the rig,” he said.

He’s also using the new Geoprobe® adjustable rod grip puller to simplify his fieldwork (middle right).

“I appreciate you only have to carry one and it does all the rod sizes,” Edwards said.

A recent job had the Illinois company in St. Charles, Missouri, collecting groundwater samples for VOCs in a municipal water well field.

“We drove 1.5-inch rods with SP16 to 100-plus feet, collecting samples at 5-foot intervals,” Edwards said. “We were doing groundwater samples at seven locations.”

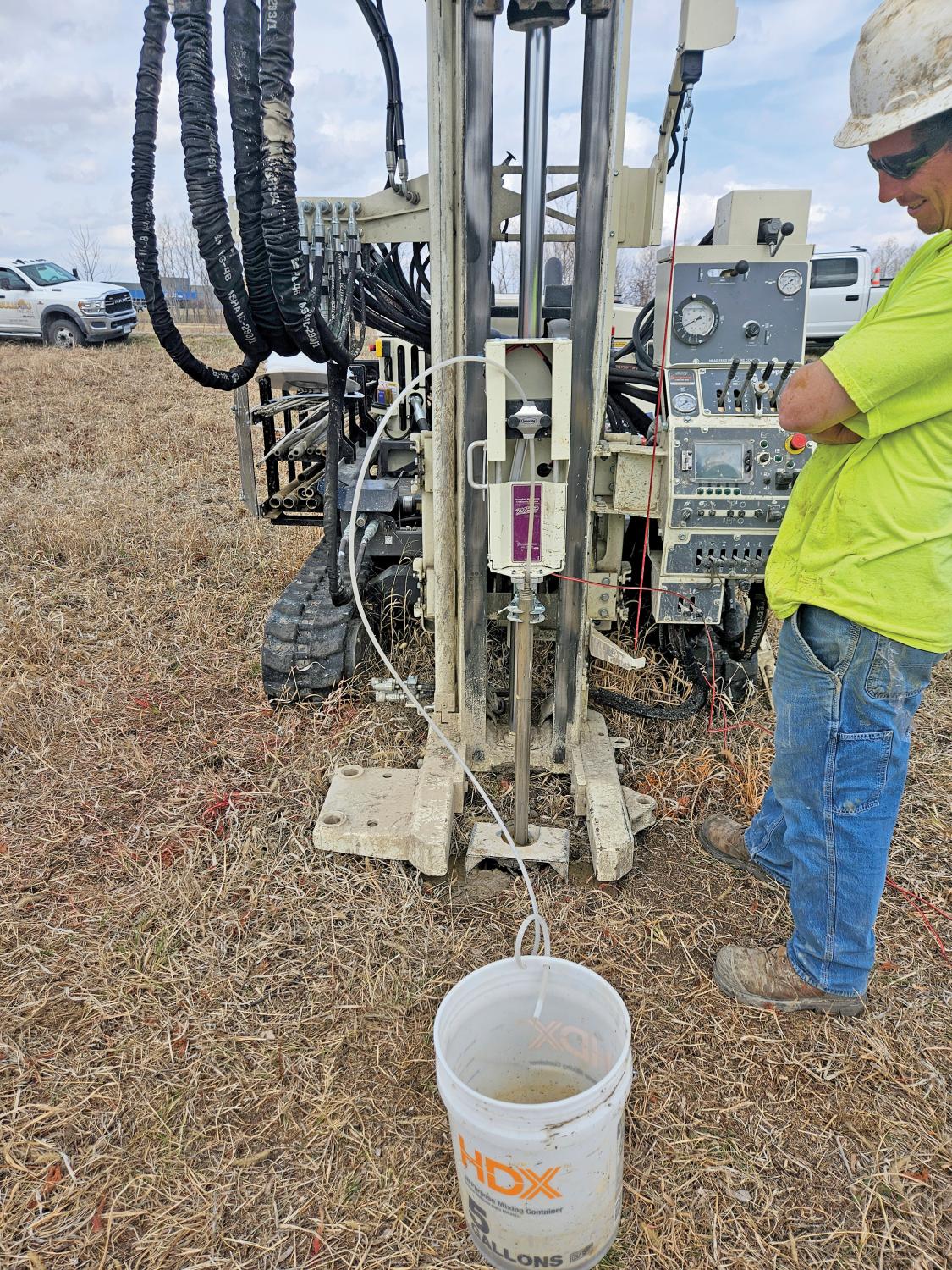

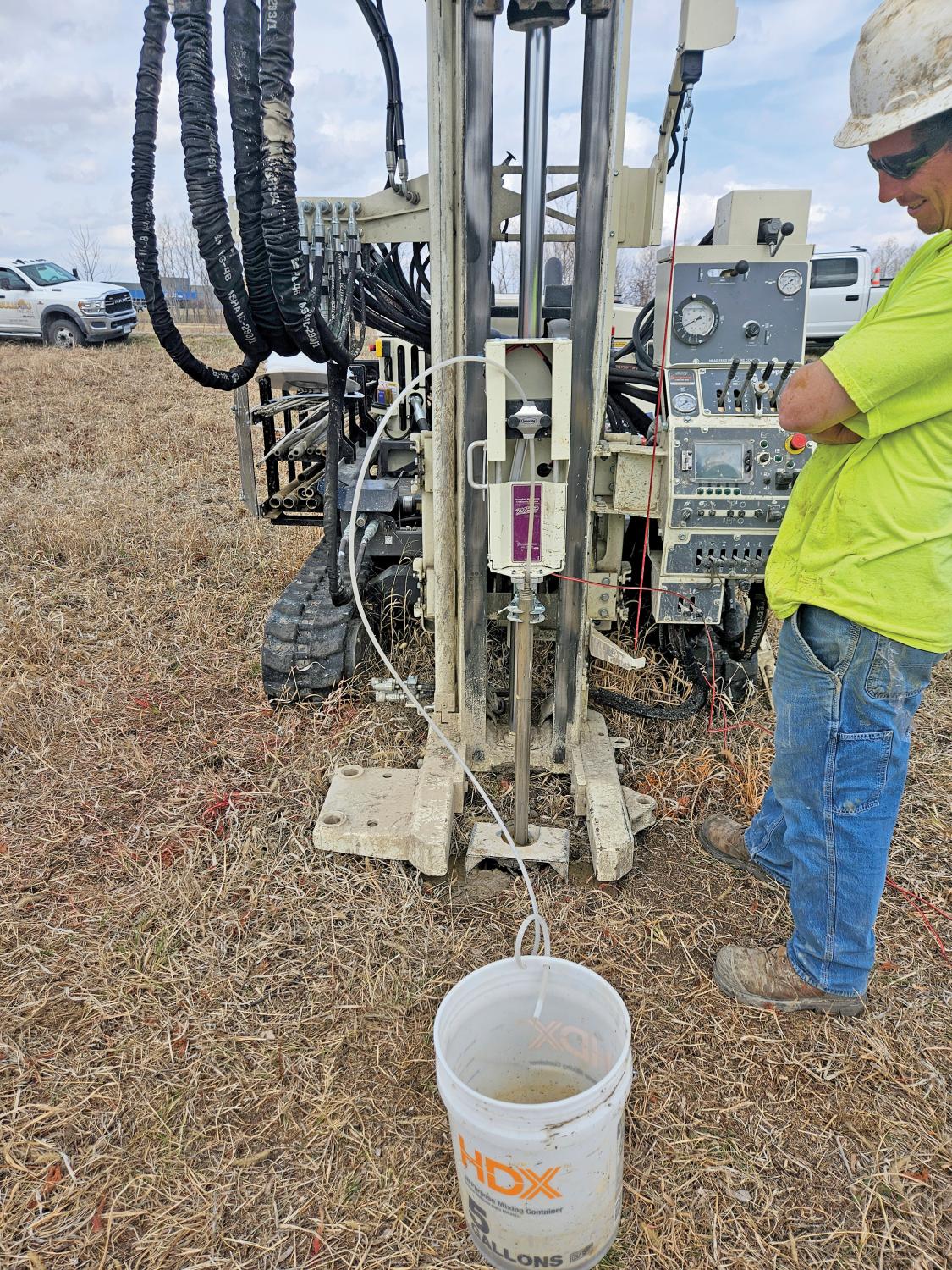

This was the first time they used the mechanical bladder pump and new Geoprobe® electric actuator (top right).

“We had some heaving sands, so we added water on the way down and developed the well before sticking the mechanical bladder pump in,” Edwards said.

The electric actuator meant they didn’t have to do all the sampling by hand.

“It kept turbidity low and hooking it up with the Milwaukee battery meant we didn’t run a cord from rig,” Edwards said. “The project went much faster.”

The performance of their 7822DT also aided their ability to complete the groundwater samples quickly.

“We were able to get the job done a lot faster than our old rig,” Edwards said. “The hammer is more efficient at advancing rods through any soil conditions. It’s also faster transitioning between holes.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Geoprobe® interlocking split spoons meet the demands of geotechnical drillers using conventional rigs.

ID: 14620 | Date:

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date: