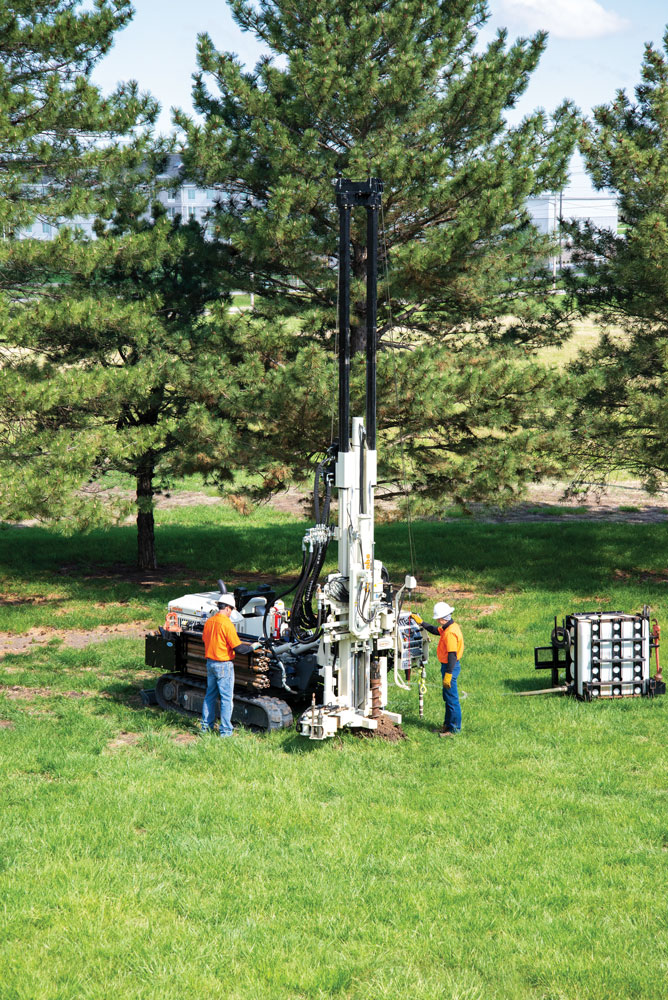

Six functions along the centerline simplify geotechnical applications like completing SPT sampling through hollow stem augers.

Reducing time transitioning between functions with the centerline head side shift is just one of the advantages afforded by the NEW 3126GT. Seasoned drillers who have watched and run the machine recognize the careful attention to a host of features addressing the field needs of the driller.

- Wider and larger track base provides additional ground clearance to tackle difficult terrain

- Hands-free rotation & feed facilitates rock coring and other rotary applications

- Hands-free automatic drop hammer reduces strain when driving SPT samples

- Telescoping winch mast with additional height for center rods suited for geotech work

- Heavy pull winch eases pulling augers and spoons

- Head shifting speeds up drilling and minimizes time driller spends in danger zone

- Separate hydraulic circuit for mud pump provides stable mud flow while extra mast dump leaves space for mud pan

- Ample, well-spaced storage includes two stacked tool boxes, helper-side storage compartments, and control panel storage bin/trays

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Adjusting mast dump to position control panel and using blade to optimize drop rack positioning make the workspace more comfortable.

ID: 14600 | Date:

3126GT versatility satisfies clients seeking multiple sampling methods, all with a single rig, while smaller footprint simplifies mobilization.

ID: 14353 | Date:

The ability to mobilize tools on drop rack and efficiently set up for boring positioned 3126GT for success on project requiring crane lift over wall.

ID: 14009 | Date:

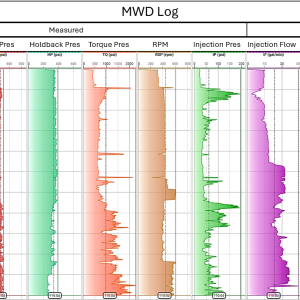

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Related Videos

MWD - Measurement While Drilling

ID: 14039

ID: 13740

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 5533

ID: 268