3100GT features increase production for MLA Geotechnical

As a locally-owned, homegrown geotechnical engineering service provider, MLA Geotechnical in Austin, Texas, was accustomed to using their conventional rigs to complete more than 250,000 soil borings in Central Texas. With the influx of people moving to Texas, they worked to meet the challenges of increasing workload by hiring and training new staff and upgrading their fleet of drilling equipment. When they found themselves in need of a truck-mounted drill rig – fast – to complete thousands of borings per year in hard clays and limestones, the Geoprobe® 3100GT quickly became their top choice.

"The advantages of the Geoprobe® 3100GT over the other rig we were considering purchasing were availability, the support of Geoprobe®, and the quality of the 3100GT itself," Tim Weston, president, said. "The quality of construction of the 3100GT is like no other drill rig we have used and we have been drilling for 55-plus years."

Conducting tools-in-the-ground testing with the 3100GT both in Kansas and Texas proved they could maintain their production levels.

“I was worried it wouldn’t push Shelby tube with the soils we have here, but it proved me wrong,” Duane Clark, driller, said. “I was worried about rock and harder subsurfaces, but it far exceeded what I thought it would do. The 3100GT does so much in a small package. I’m pleased with how well it drills and how easily it does what I need it to do.”

This means they've been able to rely on it for a near constant-level of production.

"The 3100GT has exceeded production of our other rigs due to its versatility in sampling types and ability to handle drilling in hard clay and limestone. We can easily switch from continuous sampling with Shelby tubes, to blow counts, to auger drilling with efficiency," Weston said. "The Geoprobe® 3100GT fits perfectly in the sweet spot of geotechnical drilling in central Texas. It is neither too large or too small to meet our needs, but instead perfectly fills the void. It has met the high demand of drilling thousands of borings and remains extremely reliable."

In addition to production, they also gained confidence to go after high-profile forensic geotechnical jobs.

“The rig is solid,” Shauna Strehler, operations manager, said. “From a drilling manager’s standpoint I don’t have to worry about where I send it. It’s turn-key. It does every kind of testing we provide. And with the craftmanship, I don’t have to worry about leaks or failures. I don’t worry about where I send it or what I can do. For me, that’s money.”

So now Strehler doesn’t shy away from the job with grumpy owners and their lawyers, clients and their lawyers, and her boss all standing in the driveway watching the work.

“It made me nervous to take our old equipment. It was often a volatile rig and you didn’t know what you would get,” she said. “With the 3100GT, I know I can show up, turn the rig on, do what I said it would do, and it won’t create more problems. That is a huge stress relief.”

Clark credits the rig with more good days on high profile jobs.

“A good day at a high-profile job equals more jobs through word-of-mouth,” Clark said. “I know our other rig didn’t do that for us.”

For Strehler, the dependability isn’t just because it’s new. She’s had to shut down jobs for weeks with other new rigs because of leaks and breakdowns. She credits Team Geoprobe® and the pride each employee exhibits in their day-to-day contributions to the final product. For her a quality rig isn’t the only thing she’s gained.

“We’ve actually gained production level. It drills just as many holes as the conventional rig we were used to, but it does better in many ways,” Strehler said. “We can get in and out quicker, do a better job, and leave less mess, which means the more money we can make. And we’re only putting one rig on a job versus pulling another rig, which means more profit.”

When reflecting on the work MLA has done, Strehler reminisces of a large subdivision job in San Antonio completed in 2018 where many of the houses were failing, requiring borings in the front and back yard.

“I wish I’d had the 3100GT for those 100 holes in San Antonio,” Strehler said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 3100GT makes drilling and transport on highway expansion projects easier with simple operation and no Class A/B CDL needed.

ID: 14599 | Date:

3100GT with direct push capabilities provides more accurate assessments during mine exploration.

ID: 14357 | Date:

3100GT features including easy maintenance, an extendable mast, and no deck engine simplify fieldwork.

ID: 14356 | Date:

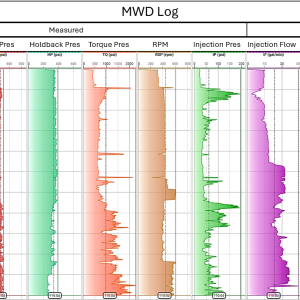

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Related Videos

MWD - Measurement While Drilling

ID: 14039

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 13370

ID: 5533

ID: 268