Geoprobe® Seismic Cone Penetration Testing Module

A multiple-city-block warehouse began showing cracks two years after construction. Called by a third-party to conduct seismic CPT testing, Hillis Carnes in Maryland ran into issues.

“When using another manufacturer’s seismic CPT, each time we passed through groundwater it would short out and give us a hard time,” Fernando Garcia, in situ testing supervisor, said. “We sent the cone to the manufacturer for review, testing, and calibration. Two thousand dollars later we went back to the site and again could do CPT, but when we’d try to run seismic we would have problems.”

Garcia called Geoprobe® for help. Troy Schmidt, CPT specialist, quickly sent equipment.

“With the Geoprobe® seismic CPT module and Nova Cone we finished the job without any problems. Collecting seismic CPT data has never been as easy as it is now,” Garcia said. “The option to see arrival of the wave and see the wave velocity increasing or decreasing is amazing. So much so, I’ve already asked for pricing to see if I can get it in the budget.”

From previous experience, Garcia believed to get accurate waves required removing an 8-foot section of foundation. However, the client limited concrete removal to the size of the cone. With the software gain option on the Geoprobe® seismic they were able to ensure they got good data.

“With the other manufacturer and no post processing on site, we would have to wait until we got to the office to realize we’re not getting what we’re looking for. Being able to visualize the arrival and the previous arrival is really good,” Garcia said. “The gaining option to make waves more clear is easy. It’s an easy way to operate. You can see the waves, compare with the previous waves, add gain, and kick it again.”

With 17 offices conducting all types of geotechnical engineering and construction testing, Hillis Carnes completes drilling and in situ testing from CPT, to flat plate dilatometer test (DMT), to pressure meter testing and all associated analysis and modeling.

“Dilatometer test was the easy way to collect seismic data, until we tested the Geoprobe® seismic CPT module,” Garcia said. “We’d been pushing clients to get seismic data with dilatometer test, but the Geoprobe® seismic CPT module is a very easy way to get seismic data.”

Having tried to conduct field work with another seismic CPT option, Garcia fully understands it is not always as simple as it may appear.

“It isn’t this easy — collecting waves, software, sensor, trigger all had a hard time — proving the theory that not everything shiny is gold,” Garcia said. “Since then it hasn’t been working and we haven’t been able to do seismic. So we need to solve the seismic CPT problem. If we don’t offer it, we’re going to be in trouble. I anticipate purchasing a Geoprobe® seismic CPT module in the next budget cycle, or sooner if a job requires it.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

The 20CPT Standalone Press can be mounted on any carrier, letting you tailor transport for your fieldwork.

ID: 14607 | Date:

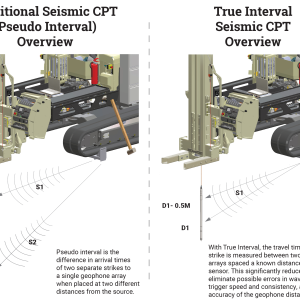

With a true interval seismic CPT module, two sensors are positioned exactly 0.5 meters apart, allowing a single hammer strike to be recorded at both depths at the same time.

ID: 14604 | Date:

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date:

Pairing the 6712DT with the 20CPT Press makes a system that is faster, safer, and more efficient.

ID: 14362 | Date:

Strength of Geoprobe® manufactured ASTRA CPT cone withstands difficult geologies at an attractive price point.

ID: 14361 | Date:

Related Videos

ID: 13740

ID: 13400

ID: 13394