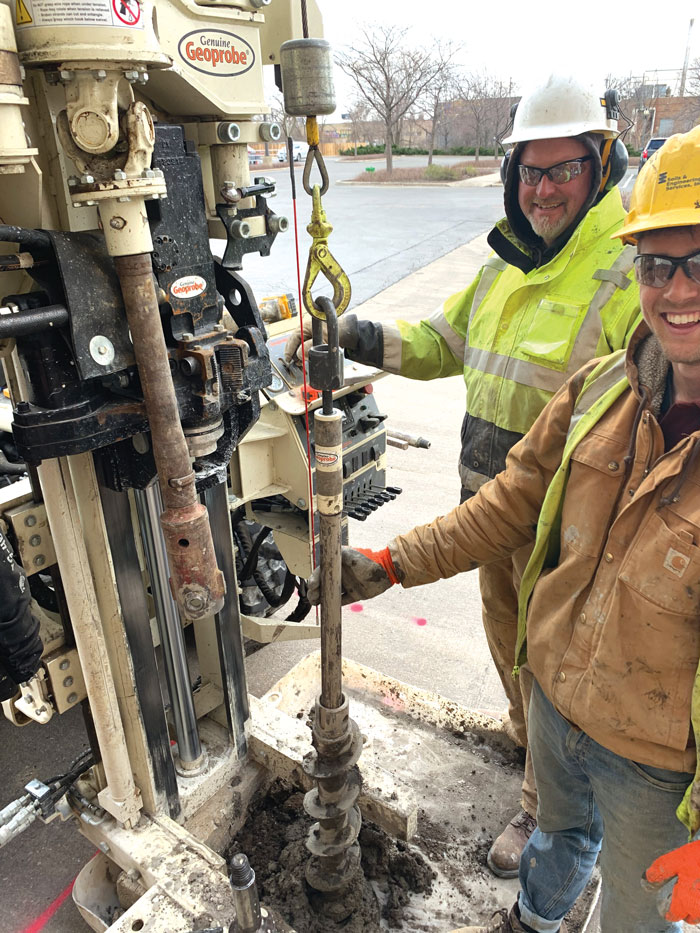

Drill crews appreciate the reduced strain and self-adjusting capabilities when threading and unthreading rods when using the Geoprobe® geotechnical drilling tools like the spring assisted swivel lift cap.

Spring Assisted Swivel Lift Caps

Watching videos of the Geoprobe® spring assisted swivel lift cap led Duane Reichel, owner of geotechnical engineering firm Soils & Engineering Services Inc. in Wisconsin, to try the geotechnical drilling tools out on their auger rigs.

“It made sense to reduce the physical strain for the operator and helper, as well as to help the rod threads to stay intact,” Reichel said. “We ordered one NWJ lift cap in 2019 and ordered some AWJ and NWJ lift caps in 2020 to start phasing out the older, non-Geoprobe®, lift caps after the other drillers and helpers had a chance to work with the spring assisted swivel lift caps.”

The crews appreciated the reduced strain and how the Geoprobe® spring assisted swivel lift cap self-adjusts when threading and unthreading rods, eliminating the need for the drill operator to bump the winch cable control up or down.

Interlocking Split Spoons

Reichel also took a leap of faith to try the 2-inch interlocking split spoon in 2018. Accustomed to the old style of sampler, this involved a bit of a learning curve, but once they figured it out, it’s working better than conventional samplers.

“They’re different than what we are used to, and being engineers, we don’t really like to try something different,” Reichel said. “One benefit of the Geoprobe® interlocking sampler is that the inside of the barrel, at the top end, is not tapered or otherwise reduced in diameter like other manufacturers’ samplers are. The ASTM D1586 standard has a figure showing a constant inside diameter for the entire length of the split barrel. This helps to minimize the potential of wedging the sample inside of the sampler and also makes the barrel easier to clean between samples.”

Other design features on the 2-inch interlocking split spoon improve its function in the field.

“We don’t worry about the sampler ‘smiling’ from overfilling or hitting on hard materials,” Reichel said. “The two halves don’t come apart like that thanks to the solid connection for the entire length of the barrel. Also nice that the threads are the same on both ends of the barrel.”

They also find the Geoprobe® shoes to be tougher.

“With the older style, if you hit a cobble, you bend or curl the tip of the shoe whereas the Geoprobe® shoe doesn’t curl over and is easier to reshape and reuse while still meeting ASTM specifications,” Reichel said. “The Geoprobe® shoes are more expensive than other manufacturers, but I’m not opposed to spending more money when the product does the work better, faster, or more accurately.”

Quality Innovations

Reichel credits Geoprobe® with quality geotechnical drilling tools and good quality control. Even when they encountered a defect with the pins not going out far enough on some DT22 detent drive heads, he praises Geoprobe® for resolving the issue quickly, replacing the product.

“We notice that there is a lot of engineering that has gone on behind the tooling that we are using, and attention to detail in the manufacturing of the tooling,” Reichel said. “The tooling is designed for the user rather than following the same design as what’s been around for 50 or more years, but still meeting the ASTM or AASHTO standards.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Geoprobe® interlocking split spoons meet the demands of geotechnical drillers using conventional rigs.

ID: 14620 | Date:

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date: