Users find the NEW Geoprobe® Seismic Cone Penetration Testing system provides an easy, cost effective means to capture seismic shear wave velocity data with increased reliability and resolution to satisfy the growing demand created by changes in the international building code.

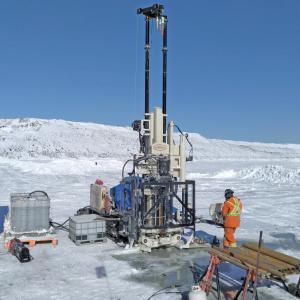

Primarily focused on completing site investigations and writing soil reports to help clients eliminate risk as they build on a new site, Applied Geotechnical Engineering Consultants (AGEC) relies on their Geoprobe® 3230DT to handle the various soil conditions they encounter around their home base in a suburb of Salt Lake City, Utah.

“We love the versatility of the 3230DT and its ability to handle every soil we have – clay, silt, sands, gravel, bedrock,” Derek Wolfe, engineer, said. “It pushes fast in clays and we can take it to the top of a mountain to do granite or sandstone coring.”

Recently the geotechnical consulting firm found themselves increasingly fielding requests to provide seismic shear wave velocity. To meet the rising demand, Wolfe sought a solution to conveniently produce reliable shear wave data.

“Recent changes to the international building code require more in terms of ground motion hazard analysis (GMHA) and it’s more convenient to use seismic cone penetration testing (CPT) to measure shear wave response in the upper 100 feet,” Wolfe said.

Geoprobe® CPT specialists Troy Schmidt and Cory Harvey brought the NEW Geoprobe® Seismic CPT (SCPT) to Utah for Wolfe and crew to examine.

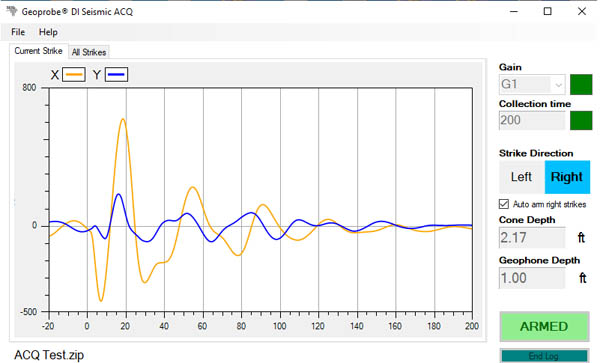

“We fell in love with what they showed us. From the first test, the software and new cone technology was more reliable, easier to use, and provided more confidence that we were bringing back good data,” Wolfe said. “With the new program Geoprobe® developed we can look at every wave collected and do a ‘sanity check’ to see if things make sense and be confident we have reliable data that can be analyzed back at the office.”

With the new Geoprobe® SCPT system, Wolfe and crew found the convenience they sought for the site investigations. They’re also saving investigation time which equates to cost savings.

“We’ve used it on three projects. It’s streamlined our ability to collect data and be confident in it.

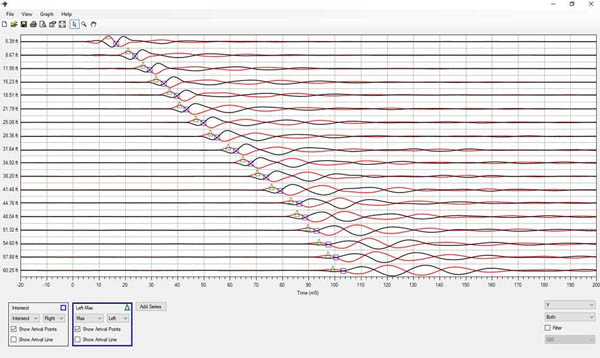

We’re able to create models faster that are more representative of what is in the ground,” Wolfe said.

“In the past it would take us three hours to analyze a full set of data. Now it can take 15 minutes. That’s a huge cost savings for us.”

Having completed side-by-side comparisons to what they’ve known to be good data and seeing it match up to the Geoprobe® SCPT data has further instilled confidence in the dependability of the system.

“We have also collected data using refraction microtremor (ReMi) on the same site and compared the data. They’ve agreed quite nicely. However, the Geoprobe® SCPT data has much higher resolution,” Wolfe said.

Being able to assess the raw data in real-time in the field also eliminates the need to remobilize and revisit a site.

“We can look at any of the 24 or 25 strikes while in the field and quickly assess if each wave arrival is happening when we would expect. It becomes apparent out in the field if there is an issue where previously we wouldn’t discover a concern until we were back in the office,” Wolfe said. “Before on a few occasions we would have to return to a site, sometimes returning multiple times, to re-push a cone because we doubted the results. Trying to remeasure shear waves at 4-foot intervals for 100 feet takes a lot of time. It’s even worse if you get back to the office and the data still seems flawed. Now we are more confident from the get go, which eliminates needing to go back and do it again. Being more confident with the initial data saves the clients bottom line.”

With changes in the building code and more likely to come, Wolfe expects to see continued increases in seismic data acquisition.

“We’re now more confident and rely on the fact that we’ll get the viable data collected the first time around,” Wolfe said.

For when they do run into an issue, they know they can depend on responsive expert customer service.

“Cory and Troy have made efforts to be at our disposal to ask questions. They’ve developed the hardware and software and their response time is exceptional,” Wolfe said. “Having that kind of customer service is invaluable.”

The level of customer service was apparent from the first visit Troy and Cory made to Utah when they asked Wolfe to identify anything missing in the system.

“We provided some suggestions for software commands and within a couple of weeks they incorporated those changes, which were critical for us being able to process and analyze the data,” Wolfe said. “They actually listened to our feedback and came back with more solutions. They’re still looking to make things better. We feel like they also have our best interests in mind because we have been heard and our opinions have been valued, which is a great advantage over many other companies.”

Advantages of the New Geoprobe® Seismic CPT Module

- Lowers the cost of adding shear wave measurement capability to your CPT system.

- Remains attached to the 10 or 15 cm2 NOVA CPT cone for seismic CPT projects or be replaced with a conventional cable adapter or acoustic signal adapter for conventional (non-seismic) projects or wireless CPT operations.

- Generates exceptionally clear, low noise, shear wave signals, requiring minimal post log filtering during data analysis.

- Uses the standard light, flexible 1/4-inch (6.35 mm) Geoprobe CPT cable – appreciated by field operators for its convenience - eliminating upsizing to a more costly, larger diameter, cable.

- Collects data using the intuitive Geoprobe® Seismic Acquisition, requiring minimal training, for quick acquisition of seismic waves displayed in entirety as the log is advance to depth with capability for signal stacking in high ambient noise locations.

- Analyzes shear waves using the FREE Geoprobe® DI Viewer software, picking wave arrival times using three separate automated methods and generating seismic velocity reports.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220