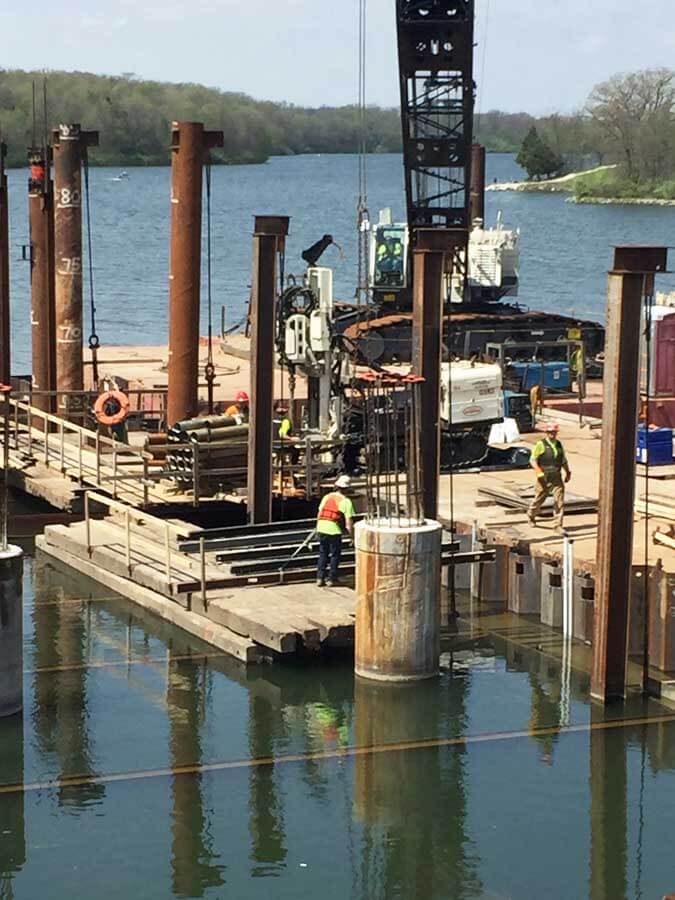

The Field Team for Major Drilling in Salt Lake City, UT, was actually not in the field but on the water for the installation of de-watering wells inside a cofferdam near Des Moines, IA. The goal of the work was to relieve any hydrostatic pressure that may exist.

“As far as rig performance goes, I have to say it did very well,” Randy Crandell, Driller for Major Drilling in Salt Lake City, UT, said recently. “I had the 8140LC rotary sonic running pretty much full power for 10 to 12 hours a day for nearly 25 days straight, and it never gave me any issues,”

Those comments pretty well summed up the results of a non-typical job on a barge in Iowa that Major Drilling completed 3-1/2 weeks ahead of schedule.

The main goal of the project was to install de-watering wells inside a cofferdam into the underlying strata to relieve any hydrostatic pressure that may exist. The work was performed on a dam near Des Moines. The various layers of soil drilled through included clays, small gravels, and sand zones.

The Major Drilling Field Team, consisting of Randy Crandell, Chris Ruschmeyer, Shaun Biggs, and Larry Thoren, were running a 6x8 casing setup while sampling with a 4-in. core barrel. All drilling was performed from the barge. The Field Team would boat in everyday to get to the rig.

The general work summary states that the Major Field Team installed 18, two-in. nested wells and four piezometers in 22 holes, 6- to 8-in. in diameter toa depth of 110-ft. They also completed continuous soil sampling below the water.

“This is a quality rig. It was a pleasure to have the 8140LC on site for this non-typical job,” Larry Thoren, Field Superintendent for Major Drilling, said. “I’ve been around all types of drill rigs, (RC, core, rotary, oil field) and now sonic and environmental rigs for 24 years, and not one of the other rigs compares with the quality of workmanship put into the 8140LC sonic rig.”

“It was also a pleasure to work with the Geoprobe® Service Team,” Randy added. “Todd Ewing is Grade A,” added Larry. “This is a quality machine; astounding! We were definitely impressed with the workmanship and customer support.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Videos

ID: 14189

ID: 12781

ID: 1919

Geoprobe® 8150LS Sonic Overview

ID: 1927

Geoprobe® 8250LS Sonic Overview

ID: 1930

ID: 1910