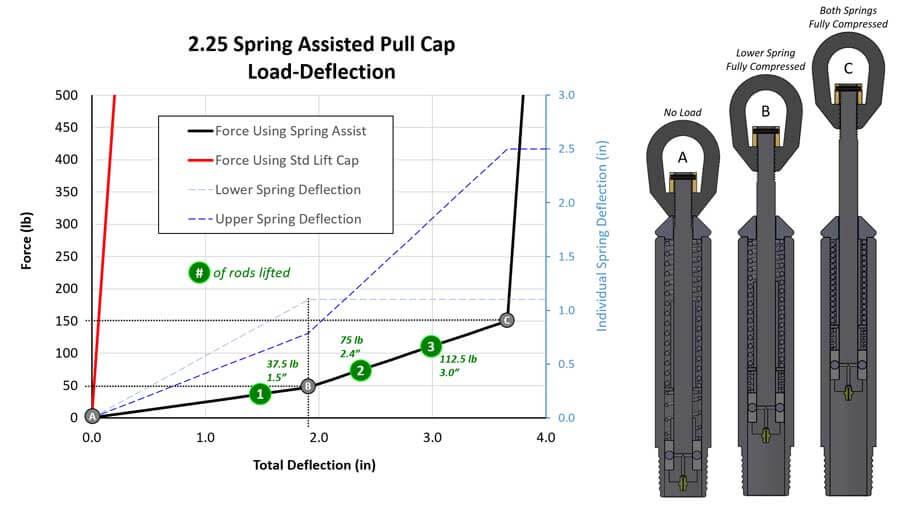

Spring Assisted Swivel Pull Cap (left, pin) 217609 and (box) 226053. Options for pin up and pin down applications.

A passionate and light-hearted testimonial provided by Lee Shaw.

This is one of my favorite accessory tools. It’s simple and effective. This is a true impact-making, gotta-see-it-to-believe-it, must-have tool for your tool box! I still remember the first time I experienced the freedom when using this accessory tool.

You see, I’m a creature of habit (stuck-in-a-rut/resist change kind of guy). I was the helper on a 3230DT while our engineers were conducting an exercise of performing multiple applications in a single borehole. From 0 to 40 feet, we collected 2-in. split spoon samples via hollow stem augers on 5-ft. intervals. At 40 to 50 feet, soil samples were collect via MC7 through 4.5-in. rods. Then we finished the boring to 115 feet using mud rotary. All this was done using the 2.25-in. rods as either center rods or as casing. At one point, as I was removing and adding 20-ft. sections of the 2.25-in. rods the operator said, “Hey, try this lifting cap with an assist spring.” He must have noticed that I was struggling with threading and unthreading the center rods. But more likely he was tired of waiting on me (remember, resistant to change, keep doing it the same way even if it’s difficult, that’s me).

I’m telling you, the Spring Assisted Swivel Pull Cap made an immediate impact on my role as the helper and the overall field experience. The days of struggling to remove and add the 2.25-in. rods were over for me. Finished. Done. No more!

We completed the remaining exercise using the Spring Assisted Swivel Pull Cap and saved time, my energy, and my hands and forearms.

By using the Spring Assisted Swivel Pull Cap, 2.25-in. center rods can now be threaded or unthreaded with minimal effort.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date:

7822DT’s power and versatility excel at pushing cones and handling diverse geotechnical tasks like here at a Nike facility in Beaverton, Oregon.

ID: 14606 | Date:

Related Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

Geoprobe® Sonic Stack Rack Overview

ID: 14115

3230DT Walkaround - Control Panel

ID: 13627