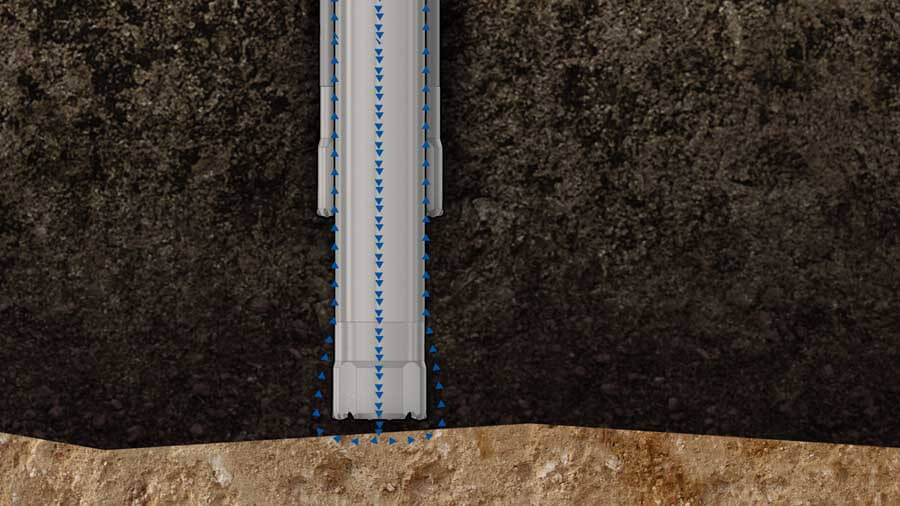

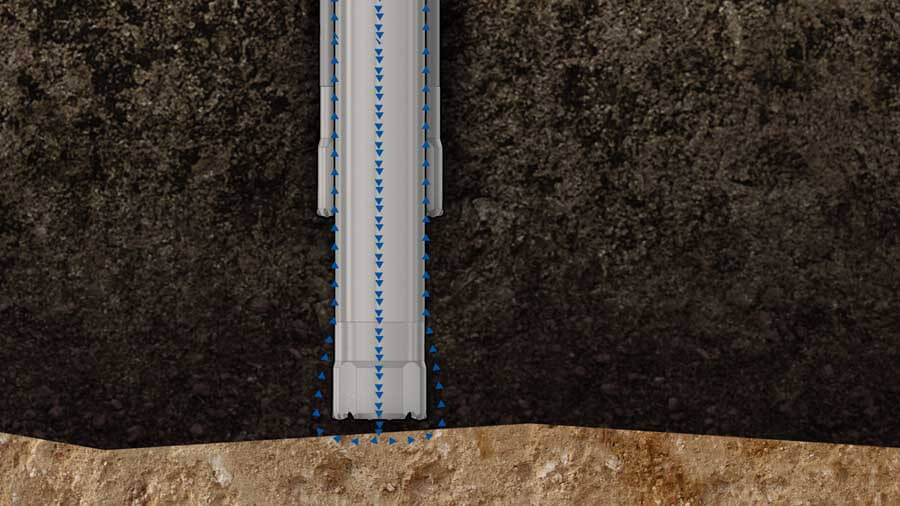

With conventional sonic 4x6 sampling, water comes in direct contact with the sample core and dramatically reduces the ability to collect a confirmatory bedrock sample.

The Sonic Double Wall 4.5-in. (SDW45) tooling system compliments the conventional sonic 4x6 system. It’s a simple and effective tooling system designed to obtain critical confirmatory rock or bedrock samples at the end of a boring, whether sonic 4x6 or sonic dual tube 4.5-in. (SDT45) tooling is used.

According to Joel Christy, Geoprobe® Tools Group and Licensed Driller, the beauty of this system is that it’s a “minimalist” system. “If you already have 4x6 sonic tooling, you can be set up to use SDW45 by adding just a few parts,” he said. There are no real limitations to this system as it can be used for environmental, geotechnical, mineral exploration, and for most projects where 4x6 is used. “SDW45 can also be used in place of our traditional sonic dual tube system when angled drilling is required,” Joel added.

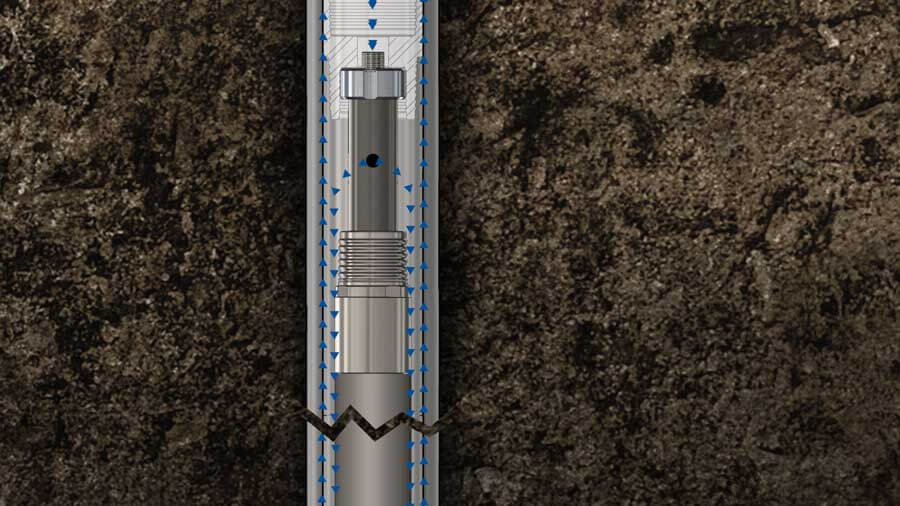

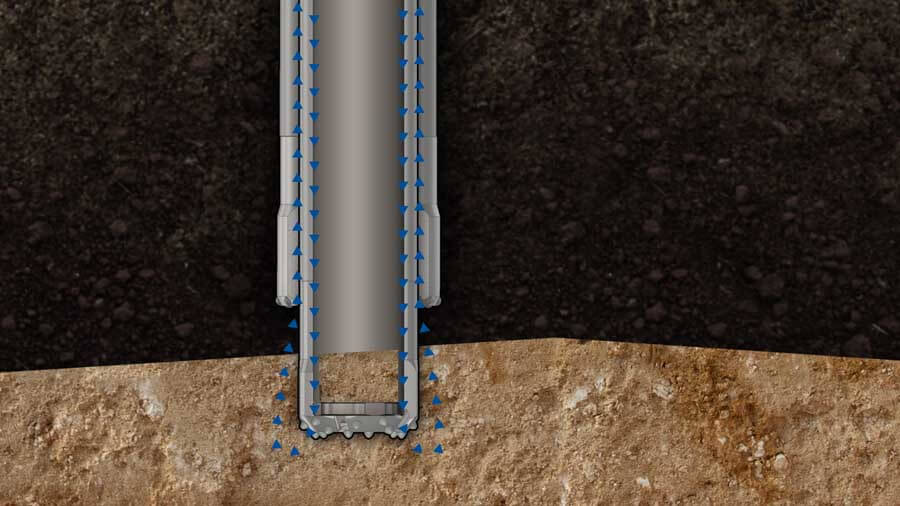

Conventional sonic 4x6 systems perform well to reach bedrock. Once you make that switch to harder, consolidated formations, it changes the dynamics downhole significantly. When taking a confirmatory rock sample, water must be pumped through the inner casing to flush cuttings away from the drill bit. With sonic 4x6, this water comes in direct contact with the sample core and dramatically reduces the ability to collect a confirmatory bedrock sample. The SDW45 method allows the water to flow around the sample sheath and exit the water ports on the bit face, leaving the sample core unaffected. “This gives you a more representative sample than a coring casing method, especially in consolidated formations,” Joel said.

One of the key benefits of this system is that conventional sonic 4x6 can be used until the operator is ready to take a confirmatory rock sample. The outer 6-in. casing can be left in place while the inner rod string is pulled. The SDW45 assembly is then lowered to the bottom of the casing using the same 4.5-in. rods. As the assembly is advanced, a confirmatory rock or bedrock sample can be taken in 5-ft. or 10-ft. increments (an optional liner can be utilized for 5-ft. increments).

- Simple and Effective Sonic Tooling System Designed to Obtain Critical Confirmatory Rock or Bedrock Samples

- Compliments Conventional Sonic 4x6 Sampling Systems

- Minimalist System ... A Handful of Parts Results in Another Valuable Tool for your Field Team

- Replaces Sonic Dual Tube System when Angle Drilling is Required

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

ID: 14598 | Date:

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

Geoprobe® manufactured 3.5 and 6.0 sonic casing.

ID: 14596 | Date:

Related Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

Geoprobe® Sonic Stack Rack Overview

ID: 14115

ID: 12781

ID: 1920