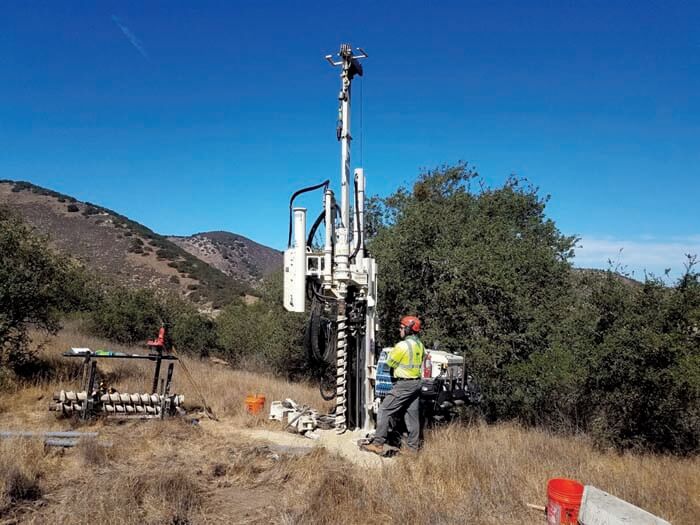

Exploration in reservoir fill abutment.

With a bachelor’s degree in geophysics from the University of California Santa Barbara, Jeff Harra’s interest in mining geology, geologic hazards, and equipment design inspired him to develop Cenozoic Exploration in 1993. The Altos, California, company specializes in limited access drilling and sampling for geotechnical and environmental industries and became Cenozoic Exploration LLC in 2018.

The newest addition to their fleet of rigs is a Geoprobe® 7822DT combination rig equipped with auto drop hammer with 140-lb. slug for ASTM sampling. In addition to hollow stem auger drilling and the auto drop hammer SPT sampling, they offer rotary wash, mud rotary, direct push DT22, Macro-Core®, and in situ water sampling.

“This is our preferred rig for installation of groundwater monitoring, vapor extraction, and shallow domestic wells,” Harra said. “We have three independent specialized tool racks that are carried to the boring locations and transport it to sites with our 2014 International 7400 4X6 semi tractor and Gatormade kingpin gooseneck air brake trailer, which makes us California Air Resources Board compliant and tier 4 compatible.”

Since adding the machine in spring 2018, Cenozoic has completed a variety of projects from rotary borings, with sampling to 80 feet, to domestic water wells to 150 feet – all producing drinkable water – with 6-inch tooling, rotary wash. Their deepest push boring has only been limited to 55 feet by their customers need.

“Between direct push projects, we are keeping the 7822DT very busy with geotechnical work, hollow stem auger with detailed sampling, modified California, and SPT,” Harra said.

Harra’s interest in geophysics and equipment design led him to design and build his own hydraulic portable machine and a crawler tractor mounted drilling rig, yet he appreciates the added capacity for their company brought by the 7822DT. “I have 26-years experience with many rigs and I am very happy with our 7822DT,” Harra said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date:

7822DT’s power and versatility excel at pushing cones and handling diverse geotechnical tasks like here at a Nike facility in Beaverton, Oregon.

ID: 14606 | Date:

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date: