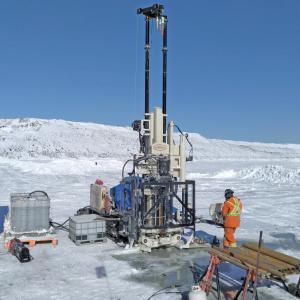

All of Hawkston LLC rigs, like this 3230DT, are equipped with automatic drop hammers and with high-speed rotary heads, ideal for advancing boreholes in consolidated bedrock formations.

After a couple years working as a consultant alongside drilling companies, Cory Walker gained key insights into what consultants need and a deep understanding of the goals and challenges of working with subcontractors. In 2015, he decided to start his own drilling business focused on improving the customer experience through service. With a focus on quality, he launched Hawkston LLC with one employee and a Geoprobe® 7822DT.

“Staying small allows us to maintain an ownership-on-site philosophy,” Walker said. “The cornerstones of our business are accessibility, transparency, and quality.”

Being small doesn’t mean Hawkston isn’t growing. The company, focused on environmental investigations and geotechnical work, has added two Geoprobe® 3230DTs and grown to eight employees. In the past year they built a new facility with a 60X80-foot shop tall enough to stand up the 3230DTs. "Three years ago it was just Cory and I and a 7822DT. That 7822DT built everything you see here," said Arnold Chapel, senior drilling manager, during a recent visit (referring to the new facility and 3230DTs).

Growth has been in part due to Walker’s mindset from the start – create the best possible customer experience and maximize utilization. All of their rigs have high-speed heads to core rock and auto hammers. This has enabled them to compete for geotechnical projects in the Nashville, Tennessee, area and expand their federal environmental work. The addition of the 3230DTs really amplified the business by enabling rock work. For Walker, the hydraulic head is the way to go for any rock coring.

"To me, 275k for an auger/rotary only rig is a lot to pay for a limited unit versus the additional 55k for a multi-application capable 3230DT. That’s a small amount based on the return,” Walker said. “With the larger head and additional weight of the 3230DT we can now run 6 and 8-inch DTH hammers with larger API rods very efficiently.”

On a geotechnical investigation outside Nashville, Tennessee, Hawkston used hollow stem augers to advance to the top of rock while collecting split spoon samples with an auto drop hammer. Upon refusal, the borings were cored using a wireline system to a depth of 110 feet.

Other work has included using the DT37 system to a depth of 54 feet on a federal power generation plant to collect nominal 2-inch soil samples thru fat clay and weathered limestone.

Walker said his crews favor the side head clamp and telescoping/oscillating mast on the 3230DT. He also finds having water onboard, with the 150-gallon drop tank, a big advantage over the 7822DT. He intends to continue to invest in the latest technology in rigs, appreciating that Geoprobe® engineers continue to push the edge of development.

“Who else has a building full of engineers that never stop?” Walker said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220