Geoprobe® Field Demo

Sometimes Dirty is Best

While seeing a new machine all shiny and new in a convention center can be impressive, witnessing a machine doing the actual work reveals its true potential. Owners, operators, drillers, and consultants observed hands-on demonstrations of the Geoprobe® 3100GT and 3230DT getting dirty – completing actual tools in the ground work – at a recent Demo Day in Minnesota.

The demonstrations, which took place at a former sand and gravel pit with 4-inch asphalt cap, illustrated how the Geoprobe® drilling rigs successfully accomplish a variety of tasks.

Following an overview of the 3100GT setup and features, the action began with 3.25-inch HSA with pilot bit and split spoon sampling; mud rotary via NWJ rods, setting a 4.5-inch conductor casing with ADH utilizing a 100-gallon aluminum mud pan; and CPT anchor and push, using a solid flight auger to clear the top 5 feet of fill.

Moving to the 3230DT, the overview included the inspiration behind its production proceeding into CPT review and pushing 1.5-inch rod with solid point; exhibiting DT37 OTE sampling with split spoons; and demonstrating the ease of installing the top spline water swivel along with discussion of rotary application.

An observer revealed their eyes were opened to one piece of equipment capable of completing a variety of drilling methods and samples, depending on material or objectives – direct push, hollow stem augering, mud rotary, CPT, and rock coring – commenting that they don’t see any other piece of equipment in the industry that can do all of them well.

Nearly 40 people braved the very cold day, many sticking around even after the demonstration concluded. Impressed by the compact size and power of the machines, many asked questions as they began to understand the alternatives Geoprobe® machines offer their business.

A participant praised Geoprobe® for being the only company innovating in an industry that has been stagnant for decades. A particular highlight was the 3230DT control panel, acknowledged for addressing a problem known as “drillers neck” caused by the driller always looking up. The swing-out feature of the panel means the driller doesn’t have to look up as high to adjust the rod or cable, positioning themselves in a safer and more strategic place.

While the additional design and development put into Geoprobe® equipment wasn’t lost on the group, one did admit that the innovation can cause growing pains – until they have a chance to be shown how it’s done. For that individual, the training and customer service – both at the time of machine delivery and then awhile later – are key factors as the Demo Day solidified the possibilities afforded by a Geoprobe® machine.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

The 3100GT makes drilling and transport on highway expansion projects easier with simple operation and no Class A/B CDL needed.

ID: 14599 | Date:

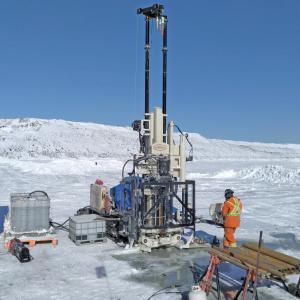

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

3100GT with direct push capabilities provides more accurate assessments during mine exploration.

ID: 14357 | Date:

Related Videos

MWD - Measurement While Drilling

ID: 14039

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 13370

ID: 5533

ID: 268