W2 uses the Geoprobe® 3100GT to complete an alignment for a running/jogging trail with bridges and retaining walls in central Oklahoma City.

Started in 2012 as a geotechnical and materials testing firm, W2 Engineering, Oklahoma City, subcontracted a lot of its drilling. According to Arvel Williams, president, they found they needed better control of their schedules and decided to move forward with drilling services both internally and externally. With more than 30 years of experience in the industry, the W2 management team began doing its due diligence reviewing all of the various manufacturers.

“What we found is that almost all of the manufacturers have not improved on their equipment over the past few decades,” Williams said. “Except for carriers, auto hammers, and moving to more modern engines, most of the mechanical drill rigs were the same design that was used 40 years ago. Almost all of them were above CDL, which, in this day and age, causes administrative issues. Where the rig was below CDL, it was usually underpowered for HSA drilling.”

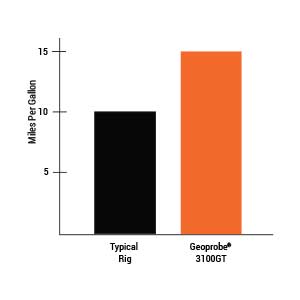

However, the Geoprobe® 3100GT was set up to drill for geotechnical work and had the features and power they were seeking. From a management perspective, W2 especially appreciates the rig doesn’t require a class A/B Commercial Driver’s License (CDL) and the fuel mileage, resulting in significant overhead cost reduction.

“Most rigs get 8-10 mpg or less. We have seen an over-the-road mileage of up to 15 mpg,” Williams said. “This is a reduction in fuel cost of 1/3. Combine that with maintenance on only one engine and we anticipate the operating overhead will drop significantly using this piece of equipment.”

From an operations perspective, the driller values the hands-free controls along with the quietness of the 3100GT. The driller appreciated being able to actually carry on a conversation next to the rig when its drilling. According to Williams, at 40 feet, wet rotary with pump and rotation the sound level was 70-73 dB at the drillers station.

W2 recently completed a 21-hole alignment through some undeveloped areas of central Oklahoma City. The 3100GT performed SSA, HSA, and wet rotary drilling with both SPTs and Texas cones. Formations varied from alluvial terrace with fine saturated sands to hard sandstone with SPT blow counts of 50 for ½ inch.

“We drilled to 70 feet with no issues,” Williams said. “The rig performed as promised. The secondary pump running auxiliary equipment was a big help when wet rotary drilling."

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 3100GT makes drilling and transport on highway expansion projects easier with simple operation and no Class A/B CDL needed.

ID: 14599 | Date:

3100GT with direct push capabilities provides more accurate assessments during mine exploration.

ID: 14357 | Date:

3100GT features including easy maintenance, an extendable mast, and no deck engine simplify fieldwork.

ID: 14356 | Date:

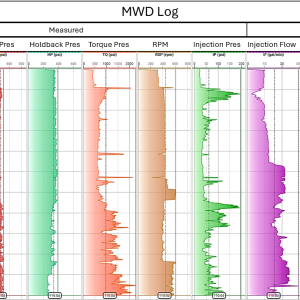

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Related Videos

MWD - Measurement While Drilling

ID: 14039

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 13370

ID: 5533

ID: 268