In business since 1965, Terracon focuses on geotechnical, environmental, materials, and facilities engineering. The exploration services group primarily supports geotechnical and environmental lines.

Terracon’s intrusive exploration and sampling methods include hollow stem augering, mud and air rotary, rock coring, and direct push. They also employ in situ testing such as cone penetration testing (CPT and SCPTu), downhole vane shear, dilatometer modulus testing (DMT), pressure meter testing, borehole shear, and packer testing.

At Terracon, intrusive methods are complemented by non-intrusive geophysical methods. Their highly qualified geophysicists routinely work with a broad spectrum of clients providing geophysical information for exploration, planning, design, locating, and evaluation of a wide variety of project sites.

These geophysical methods can also provide subsurface information in remote and inaccessible areas. When combined with traditional methods, site characterization of a project can be greatly improved.

“There are many advanced techniques available to those in need of characterizing the earth. However, the ‘tried and true’ method of pounding a split spoon and obtaining an N-value is still prevalent in our industry. We need to change that,” said R.L. (Levi) Denton II, national director-geotechnical site characterization services. “Since we have a better understanding now – than we did 50 to 75 years ago – of expected conditions and the geology across the country, we should select the specialized tools best suited to analyze those expected conditions.”

Creating Efficiencies

With the advancements of in situ techniques, Terracon can more readily and directly measure engineering properties in the field then apply the results to their engineering work.

“When we couple in situ testing with traditional methods of sampling and laboratory testing, we have a more complete picture of the subsurface and understanding of how the subsurface will interact with the built environment above and within it,” Denton said.

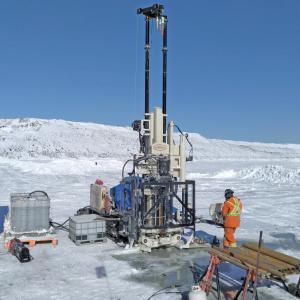

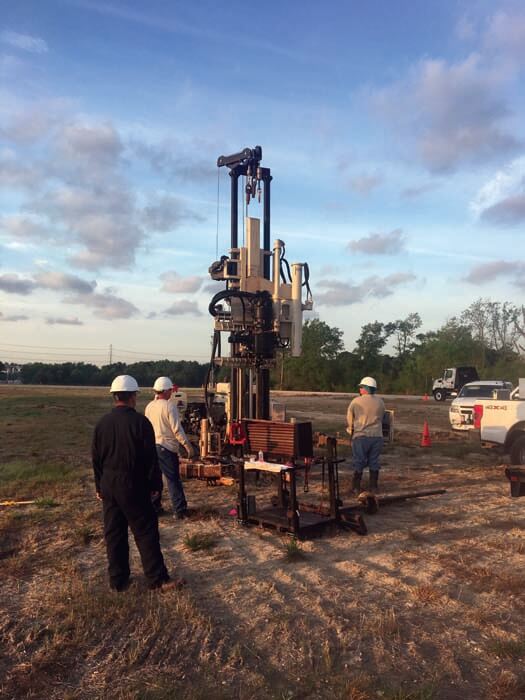

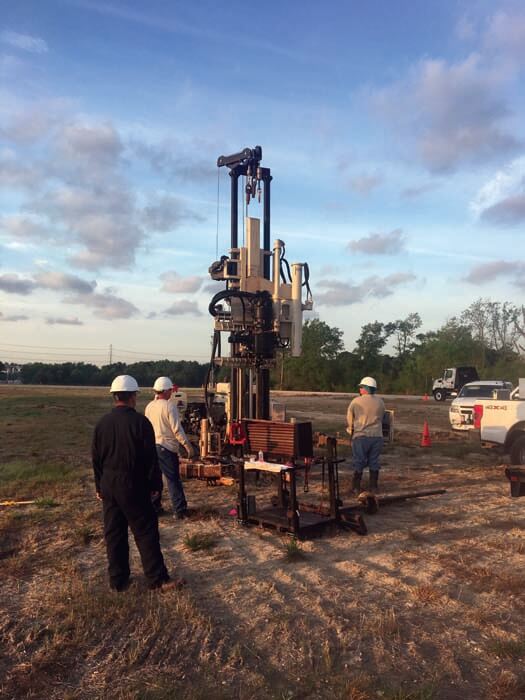

This is a step up from solely obtaining disturbed/undisturbed samples from the field to bring in for laboratory tests. Terracon uses the Geoprobe® 3230DT with the ability to perform the traditional subsurface exploration with the additional capabilities to switch over and perform the more sophisticated exploration techniques such as CPT and DMT testing.

"The efficiencies result when we can use the same piece of equipment to do both in field and react real time to the subsurface conditions we encounter to perform the most well-suited exploration program for those conditions," Denton said.

As Terracon explores more sites in any given area of the country, their understanding of the subsurface conditions encountered in those areas increases. The knowledge of these existing conditions allows them to do more analysis upfront without the use of intrusive techniques. This could be in the form of predictive and statistical analyses, which increases in confidence as the datasets become larger and more searchable with time.

“We believe those who focus on these new capabilities and couple them with tailored exploration and site characterization programs will be the industry leaders,” Denton said. “With the long history of Terracon, we have ample amounts of existing data and have prioritized using it to supplement our traditional exploration methods to serve our clients and the profession. We will continue to expose this information in new and useful ways in the future.”

The Geotechnical Field of the Future

When considering the future of the geotechnical field, a top-of-mind topic is the safety of the men and women performing the work. Historically, the drilling industry has had a reputation and track record of being a “dangerous” industry. Terracon doesn’t feel this has to be the case with careful planning and attention to training and technique.

“The newer in situ techniques have the potential to eliminate some of the rotation and more dynamic techniques associated with traditional exploration work,” Denton said. “I look forward to the day when the industry doesn’t injure another person in the conduct of our work.”

As they pursue their vision of the future for the geotechnical/exploration industry, Terracon considers Geoprobe® a trusted partner both in terms of new technologies as well as tailoring machines to be operator friendly.

“I see many opportunities for advancements in the fine details: ergonomics, well placed controls, efficiency, versatility of machines, and enhanced safety features,” Denton said. “Geoprobe® has demonstrated they are willing to partner with their customers and lead in these areas.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220