Size Comparison: 7822DT vs. 3126GT

No one wants to be stuck in the stone age, which is what it can feel like trying to squeeze profits out of a clunky conventional drill rig. The old dinosaur lumbers into position completing only one application while guzzling fuel and spitting fluids before breaking down – putting you behind schedule and over budget. Meanwhile you dream of a modern-day machine that swiftly slides from rotary to automatic drop hammer even to CPT or direct push without having to reposition mast or machine.

This innovative centerline head side shift is a reality on the compact, off-road NEW 3126GT.

Advance augers with the 2 or 4-speed rotary head. Then use the machine hydraulics to slide the head over to position the hands-free automatic drop hammer for driving SPT samples between core runs. Or use the controls to slide the head the other way to conduct CPT logging using the integrated CPT head-feed rate controls complete with cone overload protection. Or use the GH6300 direct push hammer to see the subsurface with Direct Image® tooling. No manipulating the mast position. No mobilizing multiple machines.

So forget the days of herding multiple rigs to a job site. Forge a brighter future using the centerline head side-shift to simplify the process of traditional geotech techniques - augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT - and even direct push. A taller telescoping drill mast specifically designed for geotech work with heavier winch options, 105” head travel, and 36k push and 48k pull at the head-feed cylinder means greater pull back – ideal for drive and wash – and head travel than the competition.

All this within a smaller footprint than the relic you’re used to, which still includes room for a separate hydraulic pump for the mud pump (stabilizing mud flow) and space for accessories.

But don’t fret about having to break the bank to afford becoming an industry leader. The price point comes in lower than the competition, and all the features minimize your operating costs. The end result – launching your drilling production and profit light years ahead.

Already a fan of the 7822DT?

If you’re accustomed to the advantages of the industry-benchmark 7822DT combination machine, then you’re familiar with the wide-range of work it can accomplish. The NEW 3126GT turns the efficiency dial up another notch.

- Larger undercarriage for better off-road capability

- Space to work above the mudpan

- Outriggers to stabilize unit when doing rotary work

- More winch capacity

- Stable mud pump flow

- Centerline head side-shift with a GH60 class hammer

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Adjusting mast dump to position control panel and using blade to optimize drop rack positioning make the workspace more comfortable.

ID: 14600 | Date:

3126GT versatility satisfies clients seeking multiple sampling methods, all with a single rig, while smaller footprint simplifies mobilization.

ID: 14353 | Date:

The ability to mobilize tools on drop rack and efficiently set up for boring positioned 3126GT for success on project requiring crane lift over wall.

ID: 14009 | Date:

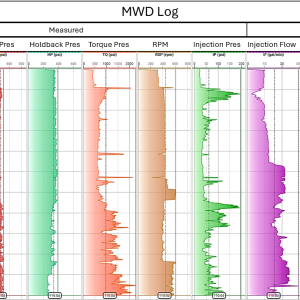

MWD takes advantage of data already available from the rig and makes it useable in other software or logging hardware for operators looking to utilize that data.

ID: 14007 | Date:

Related Videos

MWD - Measurement While Drilling

ID: 14039

ID: 13740

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 5533

ID: 268