Weight reduction from previous rig means DM450 reduces number of places requiring mud pads due to weather or terrain when installing cathodic protection systems.

As cathodic protection systems supervisor for C&S Lease Service LLC in Texas, Keith Parsons has spent the last nine years traveling roads of Texas, Louisiana, Mississippi, Arkansas, Oklahoma, New Mexico, and Colorado installing impressed current cathodic protection systems. Additional contracts mean their territory will soon expand to include Kansas. Two years ago they replaced an aging rig with a DM450, but “overwhelming” cathodic protection systems workload means their fleet will soon expand to include another DM450.

“We have enough work to keep another rig and crew busy,” Parsons said. “We experienced an uptick in efficiency with the DM450, so we decided to add another one. Instead of taking 30 hours per drive, it now takes 22-26 hours. We’re cutting drilling time down due to efficiency of the rig.”

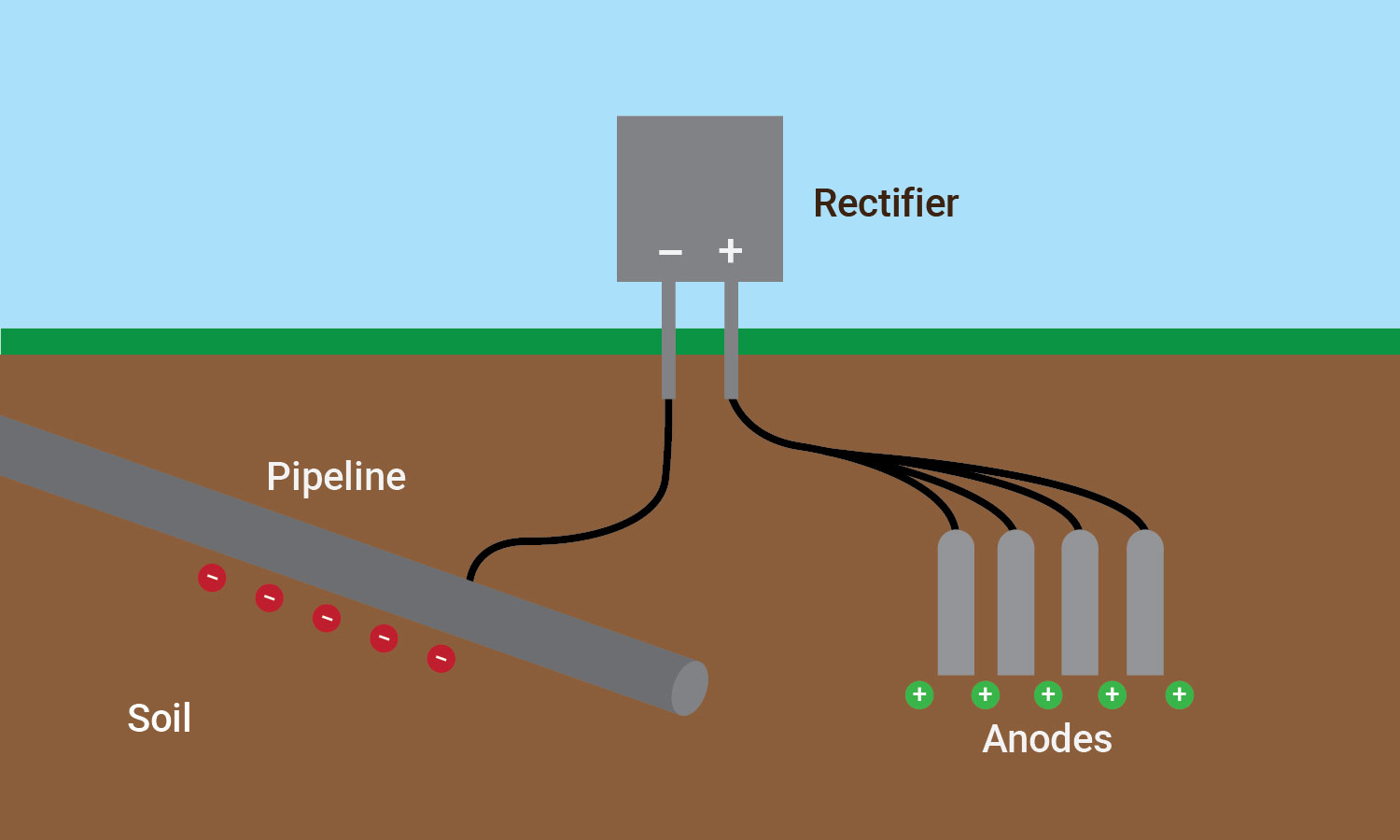

Their typical cathodic protection installation procedure involves drilling an 8- to 10-inch hole, 300 to 400 feet to place an anode tied to a rectifier. The pipeline serves as the negative, the anode the positive, and the soil is the electrolyte. The rectifier impresses a DC current, causing the anode to corrode rather than the pipeline.

“We’re working in congested areas with multiple pipelines or deep wells inside natural gas or refinery facilities,” Parsons said.

The DM450 being small and lightweight makes maneuvering on tricky sites installing impressed current cathodic protection easier.

“There’s a substantial weight reduction from our previous rig, so we can access tighter spots or maneuver in muddy conditions,” Parsons said. “It’s greatly reduced the number of places we need to use mud pads due to terrain or weather.”

The smaller size doesn’t means skimping on performance.

“It’s way more versatile and has a lot of power in a small package,” Parsons said. “We were drilling 12 ¾ with 9 2/8 to 400 feet in hard rock south of Midland, Texas. The DM450 is real efficient in drilling in tough conditions.”

He also appreciates the ease of operation and safety afforded by the DM450.

“Tripping pipe is quick and safe,” Parsons said. “It’s not hard to achieve safety the way this rig is built.”

Investing in new equipment for impressed current cathodic protection has also reduced repairs.

“The DM450 has less maintenance, less downtime,” Parsons said. “The overall efficiency while drilling is phenomenal.”

However, when he does need service support, he praises Jason Lindenmuth, rig specialist.

“Any nut or bolt, Jason knows the rig inside-out. He does a phenomenal job with any questions and is genuinely concerned with how our operation is running,” Parsons said. “He does a great job communicating with us and with mechanics at other shops to make sure we’re taken care of correctly.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date: