Articles

What do owners think about their Geoprobe® drill rig? Check out some of the stories below to learn how their rigs helped them achieve success and perhaps discover how a Geoprobe® drill rig could spark the next step in your own environmental, geotechnical, exploration, geothermal, and water well drilling business growth.

DT22 for Easier, Faster Jobs Collecting Soil Samples

Collecting soil samples using DT22 expedites process with less strain on driller and helper.

ID: 12411 | Date:

Probing Times Spring 2022

Geoprobe® Part of the Team

Drilling tool quality, - like new AWJ rods - knowledge, and service makes Team Geoprobe® another member of the drill crew.

ID: 12410 | Date:

Probing Times Spring 2022

Customer Affirms Self Service Customer Portal Centerpoint Connected

Tracking shipping information and machine service histories simplified using self service customer portal Centerpoint Connected.

ID: 12409 | Date:

Probing Times Spring 2022

Refurbishment, Relationship Wise Business Investment

Choosing a rig refurbishment makes sense while also finding source to service rigs and provide parts for long-term business relationship.

ID: 12408 | Date:

Probing Times Spring 2022

Rig Repair Service Support Vital to Growing Drilling Business

Stellar rig repair service considered part of the package price when purchasing Geoprobe® rigs.

ID: 12407 | Date:

Probing Times Spring 2022

Drill Repair Shop Service Exceeds Expectations

Southeast Service Center drill repair shop in Florida saves overhead expenses with available parts while also performing rig repair and paint to get them performing and looking like new.

ID: 12406 | Date:

Probing Times Spring 2022

LL MIHPT Site Characterization Report Optimizes Design of a Permeable Reactive Barrier

LL MIHPT site characterization report provides valuable data to ensure permeable reactive barrier contains entire contamination plume at reduced cost to initially proposed plan.

ID: 12403 | Date:

Probing Times Spring 2022

Canadian Customer Realizes Benefits of International Service

International service and support simplifies maintenance while reducing downtime for Canadian company.

ID: 12402 | Date:

Probing Times Spring 2022

Diving into Optical Profiling with OIHPT

Investing in OIHPT optical imaging system distinguishes services from other in region while providing clients a cost effective characterization.

ID: 12401 | Date:

Probing Times Spring 2022

Groundwater Sampling Methods: Screenpoint Latching Samplers Assure Integrity

Groundwater sampling methods using screenpoint latching samplers assure sample integrity by isolating the sample zone.

ID: 12400 | Date:

Probing Times Spring 2022

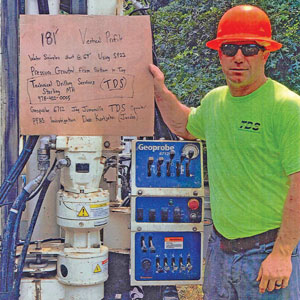

Screenpoint Sampling Project for PFAS Water Testing Proves Profitable

Scope of PFAS water testing project balloons while successfully using screenpoint sampling under 7822DT and 6712DT.

ID: 12399 | Date:

Probing Times Spring 2022

Sonic System Includes Service and Tooling Support

Cost compared with durability along with product knowledge makes Geoprobe® sonic system - drill rig, tooling, service, and support - worth the investment.

ID: 12398 | Date:

Probing Times Spring 2022

Sonic Drill Rigs and Tooling Stand Up to Alaska Geology

Geoprobe® 8150LS sonic drill rigs featuring rod handling system, dual breakout clamps, and indexing rack makes for easy operation along with tooling advice and support from team of sonic drill rigs experts.

ID: 12395 | Date:

Probing Times Spring 2022

Growing with Geoprobe®

Noticeable power difference in new 6712DT makes installing 2-inch groundwater monitoring wells to 25 feet feasible versus sending 7822DT.

ID: 12394 | Date:

Probing Times Spring 2022

Production Flies with DT325 Driven Casing Standard Penetration Testing (OTE)

DT325 standard penetration testing (SPT) out-the-end (OTE) efficiently produces borings with less mess.

ID: 12393 | Date:

Probing Times Spring 2022

7822DT Hunts for Beyond Oak Island Treasure

7822DT size and power makes it perfect tool to safely hunt for hidden treasure on Beyond Oak Island television show.

ID: 12392 | Date:

Probing Times Spring 2022

7822DT Perfect Fit for Various Drilling Methods

Ability to perform different drilling methods makes 7822DT workhorse, switching from direct push sampling to bedrock coring quickly and easily.

ID: 12391 | Date:

Probing Times Spring 2022

7822DT v3 Enhancements Make Everyone Happy

Enhancements on newer model 7822DT rigs range from function, to fuel savings, to safety.

ID: 12390 | Date:

Probing Times Spring 2022

Three Rigs in One

3230DT versatility as all engineering-type rig - environmental, geotechnical, and CPT - in a single, relatively compact package has advantage of a second hydraulic circuit for mud pump to serve as efficient mud rotary drill.

ID: 12389 | Date:

Probing Times Spring 2022

20CPT Skid Steer and CPT Equipment Economically Add Numerous Business Advantages

Adding 20CPT Skid Steer and CPT equipment provides economical way to gain footing in the CPT market.

ID: 12388 | Date:

Probing Times Spring 2022

Geoprobe® Seismic CPT Saves Time, Provides Confidence

Seismic CPT module offers processing and procedural advantages to maximize confidence in field testing.

ID: 12387 | Date:

Probing Times Spring 2022

Interlocking Split Spoon Makes Split Spoon Soil Sampling Easier

Conducting split spoon soil sampling in heaving sands simplified using interlocking split spoon.

ID: 12386 | Date:

Probing Times Spring 2022

Geotechnical Rig Checks the Boxes

Capabilities of 3126GT - including serving as a rock coring drill - makes rig ideal for array of geotechnical jobs.

ID: 12385 | Date:

Probing Times Spring 2022

Drilling Technology for the Times

3126GT gets into tighter areas and uses less fuel than a big drill truck while providing drilling technology to easily auger to depth on tough sites.

ID: 12382 | Date:

Probing Times Spring 2022

Spring Assisted Swivel Lift Caps Improve Drilling Safety

Strengthening drilling safety protocols across the company included stocking spring assisted swivel lift caps.

ID: 12381 | Date:

Probing Times Spring 2022

Comfort, Ease, Versatility of Truck Mounted Drill Expands Footprint

Simplified mobility of 3100GT truck mounted drill makes it cost effective to expand footprint and because it doesn't require Class A/B CDL expands employee base capable of driving to sites.

ID: 12379 | Date:

Probing Times Spring 2022

Features Convince Customer NEW 3145GT Suited to Off-Road, Deeper Geotechnical Work

Centerline head side shift on NEW 3145GT aligns all head functions and winches over the bore hole for efficient performance on power line projects.