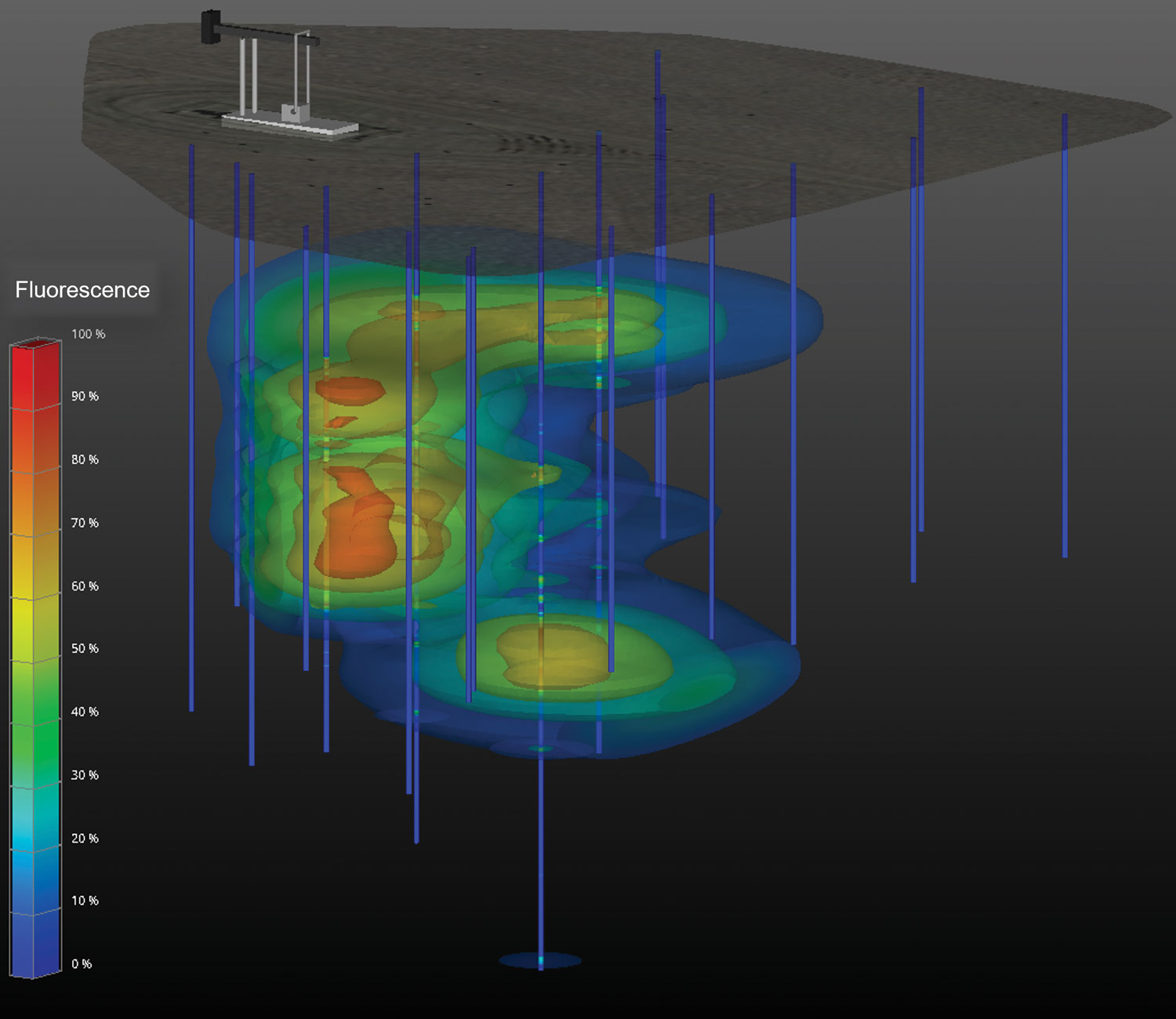

Each line represents an OIHPT optical imaging boring with colored orbs representing anything with a fluorescence greater than zero. Software used calculates volume of impacted soil remaining on site.

Starting out in 2000 as a company of three, Water & Environmental Technologies (WET) has grown to nearly 100 scientists and engineers and operates its subsidiary — Enviro Probe Services — to address its own project needs, as well as an independent contractor to assist outside consultants with site characterization services. Using their fleet of three drill rigs they’ve built the business installing wells and conducting site investigations with some injection work here and there. Seeing market opportunity and an internal need to complete their own work, they decided to venture into high resolution site characterization.

“We do expert witness work on a variety of sites, so it’s ideal when you can go with your own tools and equipment, working on your own schedule,” Pat Thomson, senior hydrogeologist, said. “The state of Montana had made a deliberate move toward using this technology to delineate sites rather than spend a lot of money on soil borings and laboratory analysis. So we investigated the Geoprobe® tooling and ended up diving in with both feet.”

Based off the sites on their docket where they needed to characterize impacted soils, they invested in optical imaging with the Optical Image Hydraulic Profiler Tool (OIHPT).Their largest project to date was in an oil field exploring a pipe line running from the pumpjack to the oil gas separator building.

“We did 56 holes to an average depth of 30 feet for a total footage of 1,680 feet. We were able to create a 3-dimensional model pretty quickly and easily and then estimate volumes of soil contamination based on the fluorescence level,” Mike Shirley, hydrogeologist, said. “The client was actually pretty impressed with what we were able to get at such a low cost.”

In addition to oil field work, they’ve discussed optical imaging high resolution site characterization options with regulatory agencies.

“There’s been some familiarity with the technology at the regulatory level from my understanding, but as a technology it isn’t top of mind necessarily,” Loran Brooks, engineer, said. “We’re just trying to bring this tactic to the forefront.”

Response from Montana Department of Environmental Quality observers was positive.

“They were very impressed with how easy it was to see and understand what was going on,” Thomson said. “You can watch the measurements right on the computer screen while you're advancing the tooling, and they were impressed with that as well.”

OIHPT optical imaging gives WET and Enviro Probe a powerful tool to provide clients cost-effective site characterization.

“You get a comprehensive study without a bunch of wells or tearing a site up,” Tyler DeBoo, engineer, said. “You can get a fair amount of OIP borings without a huge footprint.”

By choosing OIHPT, they aren’t limited to just investigating contaminated petroleum areas. With one boring, they can provide clients significant value for the deliverable.

"Having that combo tool of OIP and HPT, we can find leaching pathways, not just for contaminated petroleum areas, but also for metals or something like that,” Brooks said. “We can hammer complex sites where there might be a lot of historical uses that led to a variety of contamination, and we can address it in one mobilization, reducing costs for the client up front, but also delivering this really comprehensive product at the back end.”

WET believes bringing OIHPT to their clients sets them apart in the northern Rockies area.

“What we can do on the reporting side and give such a much more detailed and nuanced product to our clients with some expediency is where we really see this tool benefitting us and being something we can capitalize on in our region,” Brooks said.

So far client response has supported their theory.

“A lot of people have stated how pleased they are that this tooling is now local rather than having to contract farther out of our area. Now it’s all here in state,” Shirley said.

The WET team appreciates how easy the OIHPT optical imaging system is to use.

“I like how easy Geoprobe® made it for the operator to use, everything from the tool all the way down to the software. It’s a well-designed and well-supported system,” Shirley said. “It’s very easy to use and even if the tool hiccups or if anything happens, the software is able to recognize it and alert you. If it crashes, it's able to recover itself.”

And the few times they’ve run into an issue, they’ve been well supported for rapid fixes.

“I really like how accessible Dan Pipp is. I think I've only had to call him twice since we've had it, and every time he's immediately available and addresses the problem, and he tends to always get it fixed,” Shirley said.

They credit training from Dan Pipp, Geoprobe® chemist, for setting them up for success.

“It's pretty daunting on day one when you have pallets of equipment show up at your doorstep and you don't really know what anything is. After two days of training you have a very good feel for how things work and what steps to take for troubleshooting,” DeBoo said.

With the ability now to do everything from site investigation all the way through reporting to the remediation phase in an expedited fashion, the WET team doesn’t foresee the road with this kind of technology ending with OIHPT.

“I could imagine us stepping further into this sphere by adding more tools to characterize sites in a variety of ways after these fulfilling experiences we've had so far with OIHPT,” Brooks said. ’We've been able to meet our expectations with it and not underperform on anything we've tried to do with it so far, so it's been a pretty rewarding experience for sure.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date: