The Geoprobe® 8150LS Sonic rig and Geoprobe® 4.5 Heavy Duty (HD) sonic drill rods.

The Geoprobe® 4.5 in. heavy duty (HD) sonic drill rods are significantly stronger than their traditional counterpart and manufactured at our facility in Salina, KS.

“As we worked with a growing number of clients utilizing the power of the Geoprobe® 8150LS GV5 sonic head to go deeper through more difficult subsurface formations, our engineering team recognized an opportunity,” Engineer Jed Davis said.

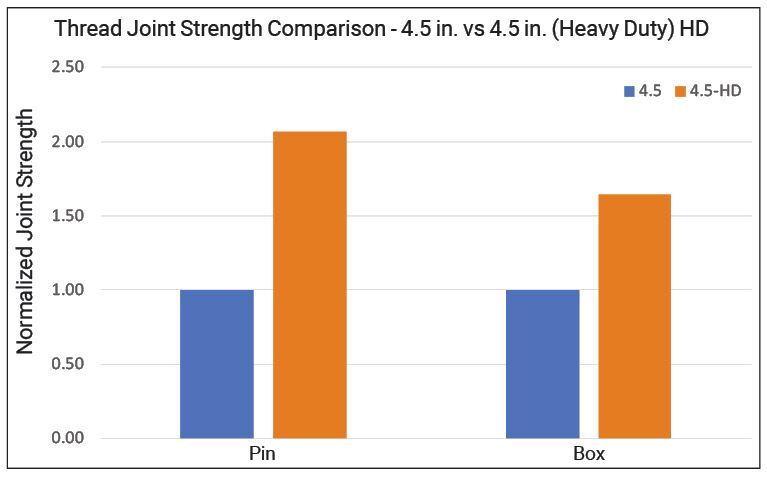

The Geoprobe® 4.5 in. HD sonic drill rods are engineered to withstand continuous use in harsh conditions and complement the 8150LS full-size sonic rig with 50K dynamic force, which was designed to continuously sample and set casing in excess of 300 ft. in a wide range of formations.

The Geoprobe® 4.5 in. HD tooling consists of two pieces – the sonic drill rod and the coupler.

“The two-piece design allows you a lot of versatility,” Jed said. “Sometimes you need to pin up or pin down and with this you can piece and part stuff together.”

Its unique design incorporates break out flats into the coupler to minimize wear on the jaw pads when breaking tool joints apart. The two-piece design also saves tooling costs, allowing just the coupler to be replaced if the threads are damaged.

The rounded pin joint speeds up the stabbing of joints together for a faster connection. The tool joint also has a larger cross section, which helps strengthen the drill rod and maximize overall thread life.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

ID: 14598 | Date:

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

Geoprobe® manufactured 3.5 and 6.0 sonic casing.

ID: 14596 | Date:

Related Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

Geoprobe® Sonic Stack Rack Overview

ID: 14115

ID: 12781

ID: 1922