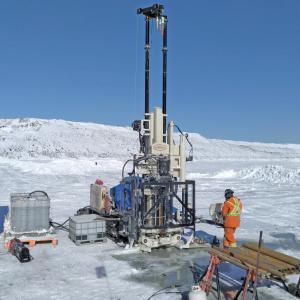

Shepler Well Drilling, Inc., completes split spoon sampling in Traverse City, MI, as part of a geotechnical site investigation for a new parking deck using their Geoprobe® 3230DT. The torque and pull back on the 3230DT put the crew at ease knowing they can retrieve their augers no matter what depth they reach on projects. Pictured are Operators Cole Shepler and Clint Bridson with Shepler Well Drilling.

Shepler Well Drilling, Inc., of Manton, MI, was in the market for an auger rig when they set their sights on the 3230DT.

“When Geoprobe® told me they could give me 8,500 lb. of torque with 80,000 lb of pull back, I knew the 3230DT would be the right machine for us,” President Randy Shepler said. “The coring and probing capabilities are just a bonus. When we are doing deep auger jobs, the 80,000 lb. of pull back provides peace of mind knowing you will be getting your augers back out of the hole.”

The 3230DT has also made mobilization easier.

“We can show up on a job site with one machine and have the capabilities to do everything needed — probing, auger, drill, coring, and rotary with the 3230DT.”

It’s even opened up opportunities for new types of work.

“With the 3230DT we were able to complete a job that required us to have no soil cuttings to be disposed of,” Shepler said. “We set the 2 in. wells with the 4.5 in. rods, gravel packed and grouted in place, and didn’t produce any soil cuttings. Before, we would not have been able to even bid the job.”

The Shepler team enjoys testing the power and performance of the machine with each new project, too.

On a recent environmental project in Johannesburg, MI, the team drilled with 4.25 in. augers to 185 ft. with split spoon soil sampling every 10 ft., dry sand and gravel to 175 ft., and set a 2 in. well at 185 ft. At the second site they drilled with 4.25 in. augers, hit water sand at 6 ft., drilled to 195 ft. and set a 2 in. well.

They also completed a geotechnical project in Traverse City, MI, for a new parking deck to be built.

“This machine makes completing the job so much easier tripping the AW rods in and out of the auger / 3-70 ft. and 6-35 ft. water at 15 ft. with 4.25 in. auger with split spoon sampling every 5 ft.,” Shepler said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220