21FH Foundation Drill Rig

Less Downtime. More Drilling.

Foundation drillers who need equipment that can take the punishment of daily production choose the Geoprobe® 21FH Foundation Drill Rig. Engineered, manufactured, and supported in North America, the 21FH is built on field-proven Geoprobe® engineering trusted across geotechnical and geothermal drilling.

With a fully articulating drill mast, oscillating tracks, and a Eurodrill double head, the 21FH delivers the reliability and efficiency required for installing micropiles, tieback anchors, and soil nails day-after-day.

Key foundation drill rig advantages include:

- High-performance breakout system with 40-inch top clamp travel

- Next-generation kinematics with seven joints for versatile positioning

- Durable, predominantly mechanical controls for long-term reliability

Micropile Drills, Tieback Drills Designed to Simplify Service

Powered by a 275 hp CAT® engine, the 21FH foundation drill rig is engineered to reduce downtime and simplify troubleshooting in the field. Owners rely on continuous innovation and industry-leading customer support to maximize daily production and improve rig utilization.

Service Focused Design Features on Foundation Drill Rig:

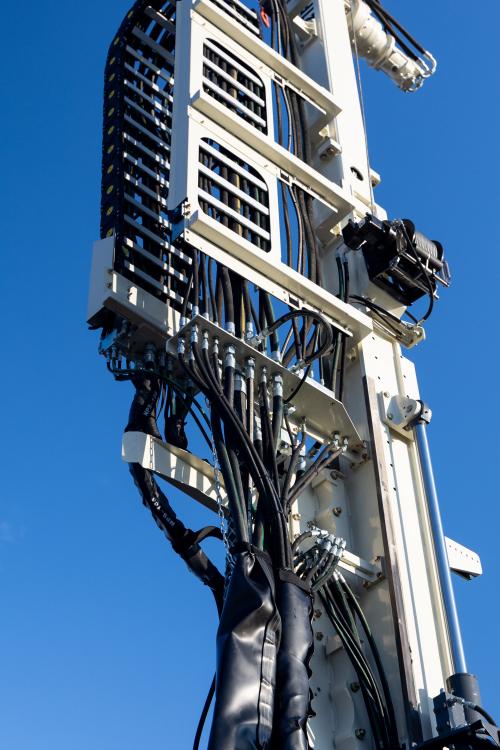

- Plumbing routed around the engine compartment

- Multiple bulkheads for easier hose troubleshooting

- Breakout components replaced individually as they wear — no full breakout replacement

- Direct access to expert service technicians — a live person answers the phone

- Nationwide network of service centers

Drill Rig Telemetry

Use NEW drill rig telemetry to view live data from your machines. Monitor rig location, operating hours, fuel use, and error codes without leaving the office to stay ahead of maintenance and track performance, keeping every rig at its best.

Features & Options

Seven-joint, next-generation kinematics for drilling in tight environments means 21FH rigs are well suited as tieback drills.

Foundation drilling profits are realized when jobs stay on schedule. The 21FH is engineered to meet the production pace demanded of micropile drills or a tieback drill, incorporating features that make drilling — and servicing the rig — faster, easier, and safer.

Faster: The high-performance breakout system allows the top clamp to raise 40 inches above the bottom, improving efficiency during drilling operations. With no outriggers required, rig setup is faster and simpler, getting crews to work sooner.

Easier: Service-friendly design features include plumbing routed outside the engine compartment and multiple bulkheads that simplify hose troubleshooting. Durable, predominantly mechanical controls reduce complexity, and breakout components are designed to be replaced individually as they wear.

Safer: Next-generation kinematics with seven total joints provide versatile, precise positioning in confined or restricted environments. Oscillating tracks improve traction and stability on uneven or soft ground by distributing weight more evenly. An optional diverter directs fluids away from personnel and equipment for a cleaner, safer jobsite.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, expert support is always within reach for routine maintenance or in-depth repairs. Geoprobe® service technicians are available by phone during business hours and backed by our engineering team to deliver real solutions not band-aids. Most service parts ship the same day, and every rig is built and tested to ensure long-term reliability and easier serviceability.

Don't see a feature you're looking for on your new foundation drill rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Front the Wall Kinematics

Work in restricted spaces with fully articulating drill mast suited to serve as tieback drills.

Seven-joint, next-generation kinematics enable effective tieback installation while maintaining control in tight or restricted environments.

Eurodrill Double Head with Diverter Option

Efficiently complete foundation drilling with the Eurodrill double head.

Ideal for challenging soils or sensitive environments, the double head combines continuous flight auger drilling with simultaneous casing advancement. Optional diverter directs fluids away from the operator and rig to maintain a safer, cleaner jobsite.

Control Panel

Swing-arm control panel with built-in safety features and diagnostic tools.

Predominantly mechanical controls are intuitively arranged on the swing-arm control panel for ease of use and serviceability.

Breakout

Improving efficiency while breaking out, the top clamp raises 40 inches above the bottom clamp.

High-performance breakout allows 40-inch top clamp travel. Components are replaceable individually as they wear.

Oscillating Tracks

Tilt forward or backward with oscillating tracks for better stability and traction.

Improve ground contact, traction, and stability while reducing ground compaction on uneven terrain.

Head Side Shift and Winch Options

Head side shift allows drillers to reposition over the hole without moving the mast or machine.

Optional 5,000 lb winch available to pair with head side shift.

Features & Options

Foundation drilling profits are realized when jobs stay on schedule. The 21FH is engineered to meet the production pace demanded of micropile drills or a tieback drill, incorporating features that make drilling — and servicing the rig — faster, easier, and safer.

Faster: The high-performance breakout system allows the top clamp to raise 40 inches above the bottom, improving efficiency during drilling operations. With no outriggers required, rig setup is faster and simpler, getting crews to work sooner.

Easier: Service-friendly design features include plumbing routed outside the engine compartment and multiple bulkheads that simplify hose troubleshooting. Durable, predominantly mechanical controls reduce complexity, and breakout components are designed to be replaced individually as they wear.

Safer: Next-generation kinematics with seven total joints provide versatile, precise positioning in confined or restricted environments. Oscillating tracks improve traction and stability on uneven or soft ground by distributing weight more evenly. An optional diverter directs fluids away from personnel and equipment for a cleaner, safer jobsite.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, expert support is always within reach for routine maintenance or in-depth repairs. Geoprobe® service technicians are available by phone during business hours and backed by our engineering team to deliver real solutions not band-aids. Most service parts ship the same day, and every rig is built and tested to ensure long-term reliability and easier serviceability.

Don't see a feature you're looking for on your new foundation drill rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Seven-joint, next-generation kinematics enable effective tieback installation while maintaining control in tight or restricted environments.

Ideal for challenging soils or sensitive environments, the double head combines continuous flight auger drilling with simultaneous casing advancement. Optional diverter directs fluids away from the operator and rig to maintain a safer, cleaner jobsite.

Predominantly mechanical controls are intuitively arranged on the swing-arm control panel for ease of use and serviceability.

High-performance breakout allows 40-inch top clamp travel. Components are replaceable individually as they wear.

Improve ground contact, traction, and stability while reducing ground compaction on uneven terrain.

Optional 5,000 lb winch available to pair with head side shift.

Tooling & Accessories

Videos

Specs

Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | ||

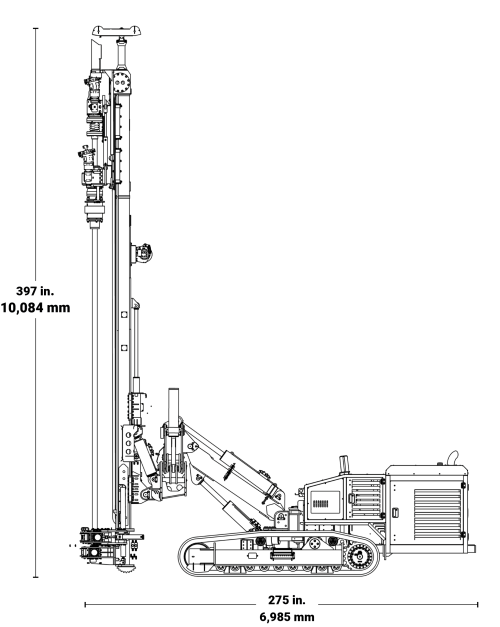

| Mast height (with winch) | 33.1 ft | Mast height (with winch) | 10,084 mm |

| Track width | 1.6 ft | Track width | 500 mm |

| Track length (CL of sprockets) | 9.75 ft | Track length (CL of sprockets) | 2,972 mm |

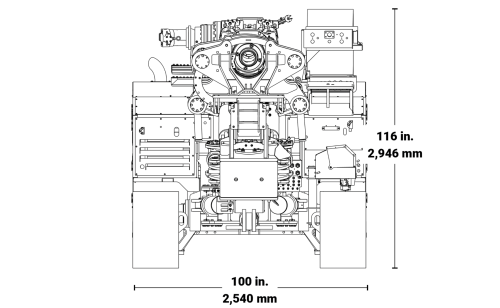

| Transport Width | 8.4 ft | Transport Width | 2,565 mm |

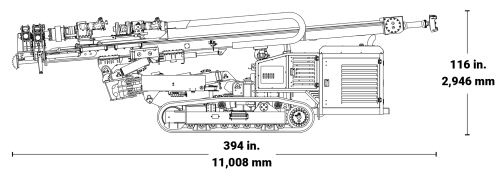

| Transport Length (with winch) | 32.8 ft | Transport Length (with winch) | 9,998 mm |

| Transport Height | 9.7 ft | Transport Height | 2,946 mm |

| Base Weight | 47,000 lb | Base Weight | 21.3 t |

| Power | Power | ||

| Engine | 275 hp | Engine | 205 kW |

| Mast and Head | Mast and Head | ||

| Head Stroke | 18.3 ft | Head Stroke | 5,578 mm |

| Top head (max torque) | 9,200 ft-lb | Top head (max torque) | 12.5 kNm |

| Top head (max speed) | 182 rpm | Top head (max speed) | 182 rpm |

| Bottom head (max torque) | 18,000 ft-lb | Bottom head (max torque) | 24.4 kNm |

| Bottom head (max speed) | 92 rpm | Bottom head (max speed) | 92 rpm |

| Feed / retraction force | 24,800 lb | Feed / retraction force | 110 kN |

| Breakout | Breakout | ||

| Breakout clamp range | 2 - 14 in | Breakout clamp range | 50.8 - 355 mm |

| Breakout extraction stroke | 40 in | Breakout extraction stroke | 1016 mm |

| Breakout extraction force | 42,000 lb | Breakout extraction force | 186 kN |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | ||

| Mast height (with winch) | 33.1 ft | Mast height (with winch) | 10,084 mm |

| Track width | 1.6 ft | Track width | 500 mm |

| Track length (CL of sprockets) | 9.75 ft | Track length (CL of sprockets) | 2,972 mm |

| Transport Width | 8.4 ft | Transport Width | 2,565 mm |

| Transport Length (with winch) | 32.8 ft | Transport Length (with winch) | 9,998 mm |

| Transport Height | 9.7 ft | Transport Height | 2,946 mm |

| Base Weight | 47,000 lb | Base Weight | 21.3 t |

| Power | Power | ||

| Engine | 275 hp | Engine | 205 kW |

| Mast and Head | Mast and Head | ||

| Head Stroke | 18.3 ft | Head Stroke | 5,578 mm |

| Top head (max torque) | 9,200 ft-lb | Top head (max torque) | 12.5 kNm |

| Top head (max speed) | 182 rpm | Top head (max speed) | 182 rpm |

| Bottom head (max torque) | 18,000 ft-lb | Bottom head (max torque) | 24.4 kNm |

| Bottom head (max speed) | 92 rpm | Bottom head (max speed) | 92 rpm |

| Feed / retraction force | 24,800 lb | Feed / retraction force | 110 kN |

| Breakout | Breakout | ||

| Breakout clamp range | 2 - 14 in | Breakout clamp range | 50.8 - 355 mm |

| Breakout extraction stroke | 40 in | Breakout extraction stroke | 1016 mm |

| Breakout extraction force | 42,000 lb | Breakout extraction force | 186 kN |

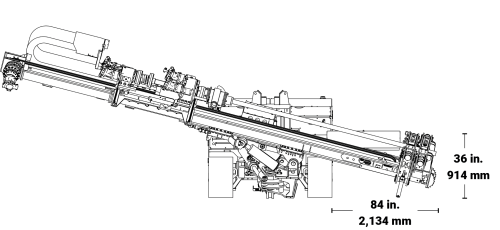

Operator Side - Unfolded

Operator Side - Folded

Front - Folded

Front - Tilted Mast

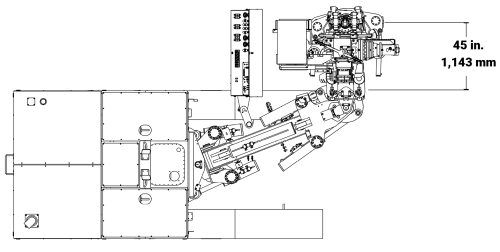

Top - Front the Wall

Resources

Click on a section below to view information.

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.