Equipment used and overall high-resolution site characterization operation layout during a MIHPT location.

Columbia Technologies has long partnered worldwide to deliver high-quality direct sensing for high-resolution site characterization. Recently, they teamed with GEOSUB and Novambientti in Colombia to handle projects from site characterization to remedial design and financial assessment.

While high-resolution site characterization is common in Brazil, countries like Argentina and Colombia are newer markets. Columbia Tech has led the way in applying Geoprobe® Direct Image® (DI) systems such as the Membrane Interface Hydraulic Profiling Tool (MIHPT) and Optical Imaging Hydraulic Profiling Tool (OIHPT) in Brazil (since 2012), Argentina (2020), and Colombia (2023).

"We count on local partners to successfully deploy the tools, improve site investigation practices, and support the creation of more robust conceptual site models," Mateus Evald, senior project manager, said.

Recently they finished a challenging project in Colombia deploying the OIHPT and MIHPT — among other methods — to acquire multiple lines of evidence.

Tackling Complex Conditions

The site was a former industrial facility with known historical impacts from chlorinated volatile organic compounds (VOCs) and total petroleum hydrocarbons (TPH). It presented several challenges:

- difficult infrastructure with unknown historical sources

- missing links between source areas and deep contaminant locations

- a complex geological setting with carbonate formations

Real-Time High-resolution Site Characterization Data Drives Smarter Decisions

The main goal for site management was to conduct the investigation to achieve a robust conceptual site model and proceed with a financial assessment of possible remedial scenarios.

"We deployed Geoprobe® DI systems from day one to acquire data from primary zones of interest and evaluate changes in impacted volume in real time," Evald said.

This approach allowed them to modify the remedial design while delimiting the source areas.

When they encountered impenetrable carbonate layers, they adapted their drilling approach. Figure 1 shows a piece of carbonate recovered from a DT22 soil sample during an exploratory sampling location to understand the lithological challenges.

"We initially tried drilling with stem auger without success and had to use a bottom hammer to crack through the carbonate," Evald said. "We were able to assess the carbonate in areas where it was more weathered, discovering that this layer was not impacted and — therefore — not of interest."

With this finding, their strategy changed from spending excessive time trying to drill through carbonate with DI tools. Instead, they conducted a shallower investigation until reaching the carbonate, then resumed deeper investigation after that layer.

"Throughout the project, DI tools allowed us to communicate effectively with the client and provide real-time updates," Evald said. "All changes in the work plan and strategy were immediately aligned with the client, keeping our end goal in focus: What data did we need to collect and where, in order to reduce uncertainties impacting the remedial design?"

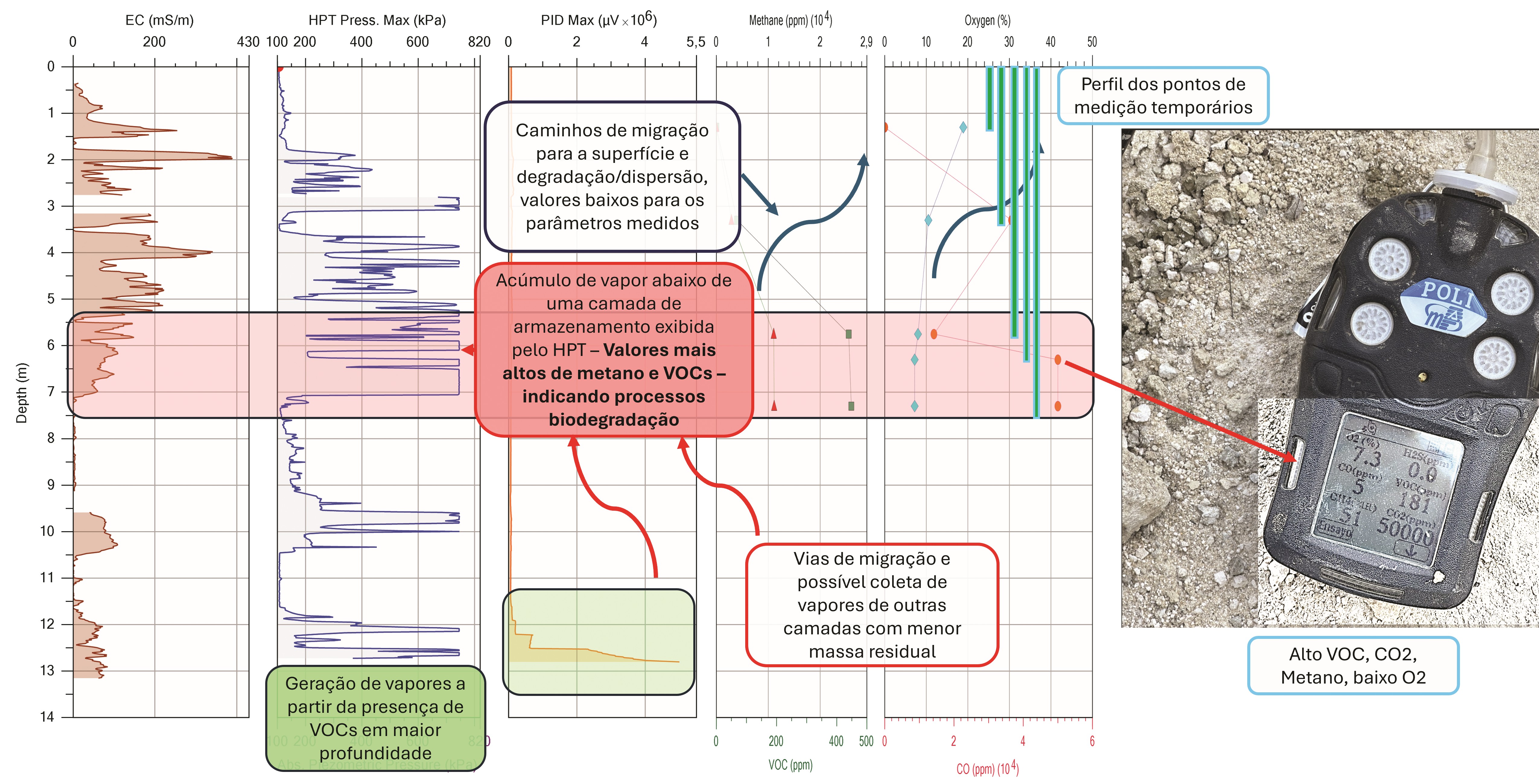

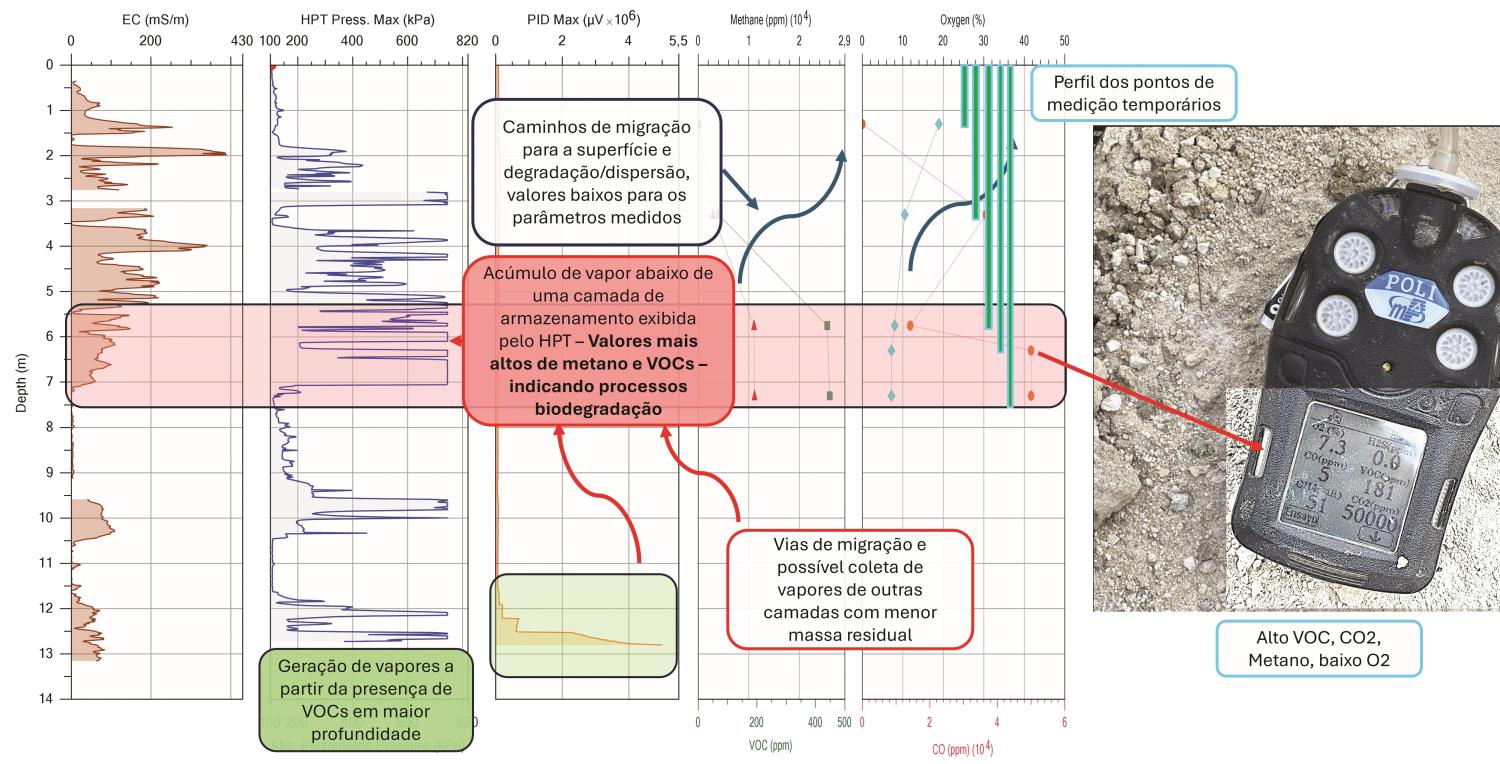

Tracing Vapor Migration Pathways

After characterizing that no shallow sources were present, the remaining uncertainty was to evidence the migration pathways of vapors generated from the contaminant mass centers. To achieve this, they installed temporary vapor probes at different intervals based on HPT data collected:

- close to the surface (1.5- and 3-meters depth)

- in a storage layer with high HPT pressure (5 meters)

- at two intervals below it (6 and 7.5 meters)

This allowed them to evidence vapor generation and migration to the surface.

"We also monitored biodegradation products including methane, CO2, CO, oxygen, and VOCs," Evald said. "This biodegradation evidence allowed us to refine the remedial design further."

Together with the client and its site priorities, a solid management and remediation plan was created and approved, with measurable key performance indicators and mapped uncertainties.

Transforming Site Investigation Practices

"Our 26 years of experience with Geoprobe® DI technologies and this Colombian project demonstrate how direct sensing technologies transform complex site investigations from guesswork into data-driven decision making," Evald said. "By adapting our approach in real-time based on the MIHPT and OIHPT results and geological challenges, we reduced investigation time while building a more accurate conceptual site model. The integration of multiple lines of evidence — from direct sensing data to vapor monitoring — enabled precise remedial design that directly addressed client priorities and site-specific conditions."

As South American markets adopt these technologies, projects like this prove that successful DI deployment depends not just on advanced tools, but on local partnerships, adaptive strategies, and clear communication with stakeholders.

"Special thanks to the GEOSUB and Novambientti teams for partnering through this excellent project," Evald said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Related Videos

ID: 14050

ID: 6608

ID: 6082

ID: 5344

ID: 1997

ID: 1975

ID: 1892

ID: 1996