Lee Shaw, Geoprobe® Sales

I’ve been operating the 3230DT since its release and the capabilities continue to impress me.

In April, we successfully used the 3230DT geotechnical combo rig to deploy CPT at a chemical plant construction site in Texas.

To be able to mobilize one track machine and then push CPT effectively with a lightweight platform in difficult subsurface conditions was essential to the customer. The 3230DT successfully met each requirement and more.

The advantage to using the 3230DT is that you have multiple drilling methods at your fingertips and can easily transition from rotary applications to CPT – all using the same powerful combo head.

Features such as the sideshifting head and rod clamp are an added bonus, allowing operators to sideshift the head without moving the machine, raise the rod with the rod clamp to remove friction, sideshift back and then continue deploying CPT.

My overall experience running CPT with the 3230DT is that it’s actually very relaxing and quiet. With the engine at idle and using the head feed rate control, I could precisely adjust the cone advancement to 2 cm/second and maintain that speed.

At some locations we pushed with just the static weight of the 3230DT, which gave us approximately 5 tons of downforce. For the deeper CPT locations we installed anchors to tie down the 3230DT drill mast before pushing the CPT cone. The anchors held and allowed us to perform the maximum 20 tons of downforce push. Impressive.

We have several customers who perform CPT and seismic CPT with the 3230DT because it has the ability to efficiently sample the subsurface using both direct push and rotary drilling techniques and then quickly transition to pushing the CPT cone.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

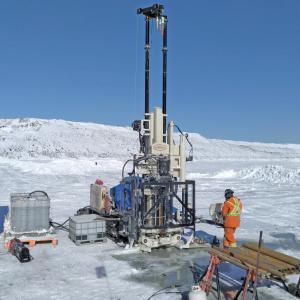

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13400

ID: 13394

ID: 5533