“The 3230DT is a departure from the conventional auger rigs we are used to operating. It has proven to be an extremely versatile machine and has exceeded my expectations in every regard.... Using the rig for cone penetrometer testing has been a major success for our crews. The efficiency with which we are now able to obtain seismic shear wave profiles has given us a unique advantage over our competition.” Benjamin Coray, P.E. • Exploration Manager, Applied Geotechnical Engineering Consultants. • Sandy, UT

Within weeks of joining the Applied Geotechnical Engineering Consultants (AGEC) drill rig lineup, they tested the limits of the Geoprobe® 3230DT on several deep exploratory borings utilizing the 4-in. direct push casing. “We were impressed that we could advance the exploratory holes through dense sedimentary soil deposits to depths of up to 120 feet with the GH70 hammer while obtaining SPT samples every 5 feet,” said Benjamin Coray, P.E. with AGEC in Sandy, UT. “For us, one of the significant advantages of the direct push system is the pull-out and clean-up time. Not having to clean augers and dispose of cuttings saves us significant time and effort.”

Using the 3230DT for cone penetrometer testing has also been a major success for the company. Using the Geoprobe® Nova Cone CPT with the addition of the seismic geophone, “We’ve easily pushed to depths in excess of 100 feet (most likely deeper if we hadn’t run out of rod),” Ben added. “The efficiency with which we are now able to obtain seismic shear wave profiles on our projects has given us a unique advantage over our competition. What used to take several days at a significant cost can now be done in an afternoon,” he said.

AGEC has also found that the 3230DT is excellent for mud rotary and coring work and is “a joy” to operate. Being able to separately adjust weight on bit, rotation speed and pump flow allows for excellent operator control while drilling in Utah’s varied soil and rock formations. They have explored to depths of up to 170 feet in Salt Lake City lakebed sediments and gravels using rotary wash methods.

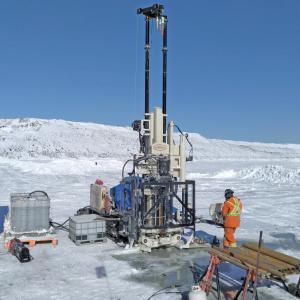

They also tested the rig’s abilities on the slopes of a local ski resort east of the city. The project required rock coring to a depth of 50 feet in hard quartzite sandstone halfway up a ski run with grades of 35 to 40 percent. According to Ben, “The rig, fully loaded with heavy tooling, climbed the slope with ease. The low center of gravity of the 3230DT gave us confidence while traversing slopes that we would not have tried with our other rigs. The mast oscillation allowed us to stay plumb despite the uneven terrain.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220