Call us today at 785-825-1842 to schedule your demonstration!

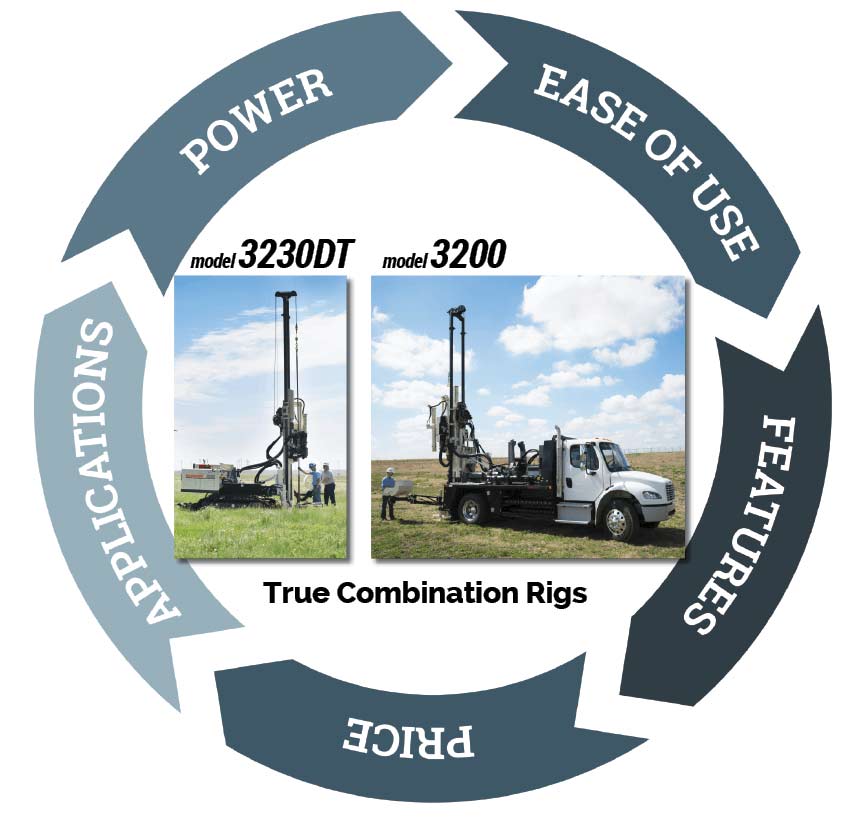

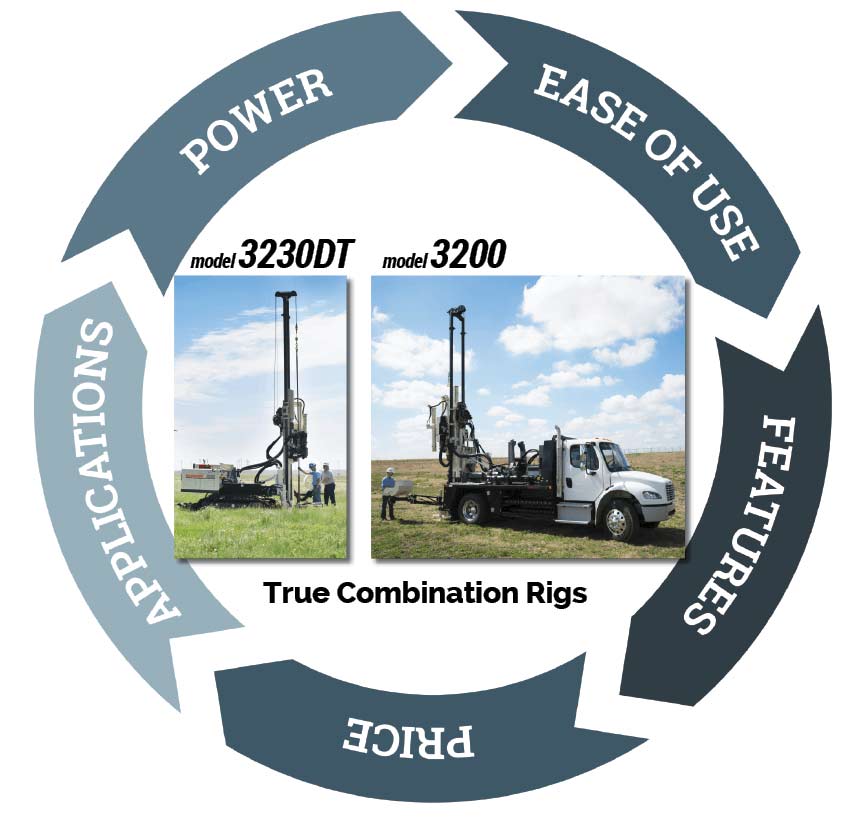

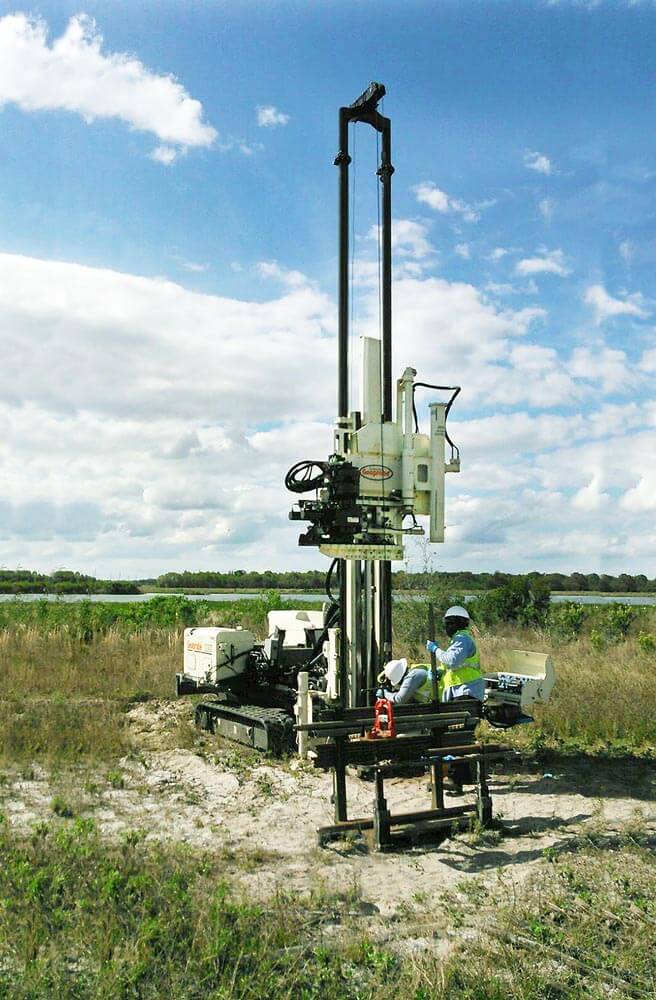

The 3230DT and 3200 are TRUE combination machines, which means their utilization rates go up simply because they are well suited for both geotechnical and environmental work.

The versatility of the 32 Series machines lies within the 4-function CB6 Combo Head ... the performance master for these rigs. There’s rotation for augering, mud and wet rotary, and rock coring work, and a patented hydraulic head clamp for safely and quickly pulling 1.25- to 6.0 in. rods while maintaining an open ID for downhole work. There’s a percussion hammer for direct push work, like driving 6-in. casing for monitoring well installation, and an automatic drop hammer that hydraulically swings out over the hole.

There’s a side-shift feature for moving the head so you can work the inside diameter of the rod without moving the drill mast.

What about torque? These machines have plenty of it! There’s low-end torque for hollow stem applications and plenty of high end speed for rock coring and air and mud rotary.

And don’t forget the control panel ... it’s adjustable, easy-to-use, and well planned. You can separately adjust weight on bit, rotation speed, and pump flow for excellent operator control in the field.

The most noticeable option on these machines is the 23-ft. telescoping mast and dual winches. They take the work out of setting monitoring wells or utilizing splitspoon samplers while tripping 20-ft. sections of rods at a time.

There’s 800 rpm for coring bedrock. There are drilling controls to do rock coring. Do you need 20 feet of rock coring done at 20 locations? This machine is perfect! And remember there’s a percussion hammer to set up to 6-in. casing.

There are way too many features, options and applications possible that make the 32 Series machines too powerful and too versatile to not take a second look at them.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

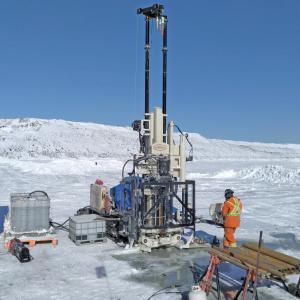

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220