|

||||||||||||||||||||||||||||||||||||||||||||||||

Below we will explain these points further:

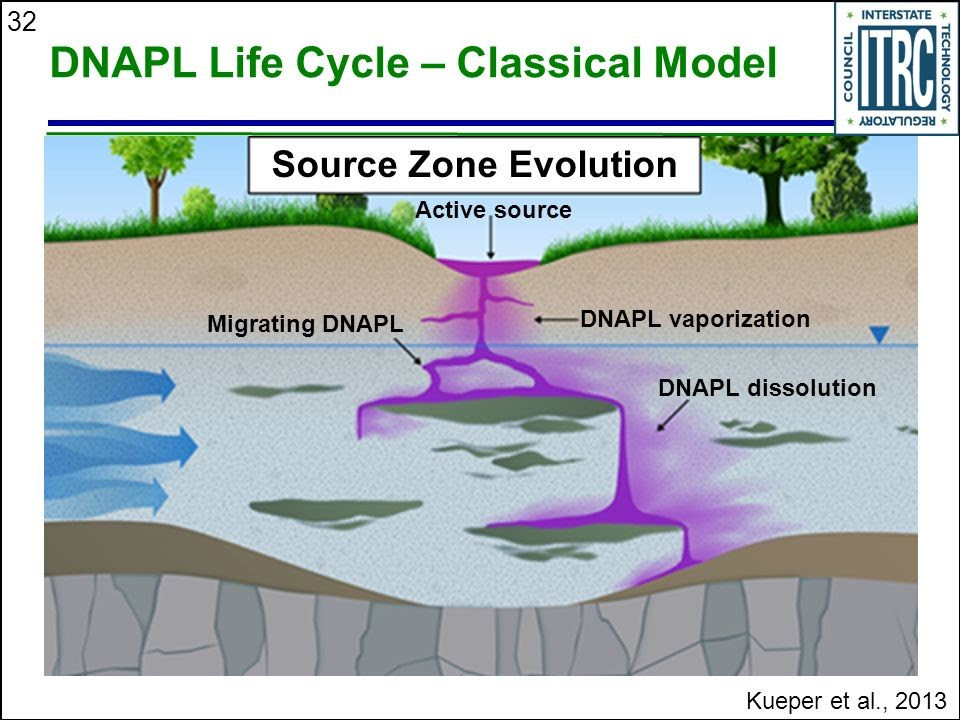

(1) Based upon the data we have seen and collected, when your detector (PID, XSD and FID) responses are reaching into the 107 μV levels there is a good probability DNAPL will be present.

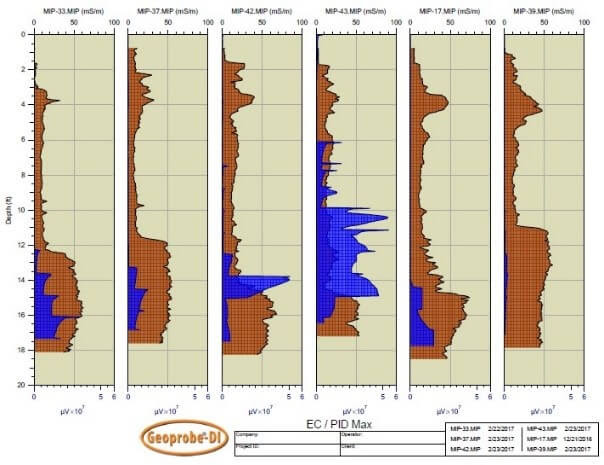

(2) Here are cross sectional displays of a series of logs (EC and MIP detector graphs). Notice the sand-till contact is deeper on the EC graph (brown fill) in the 3rd to 5th logs from the left. This will act as a DNAPL point of collection. The XSD (green fill) and PID (blue fill) both show higher responses in the 3rd to 5th logs but also have visible signal in adjacent logs at these scales.

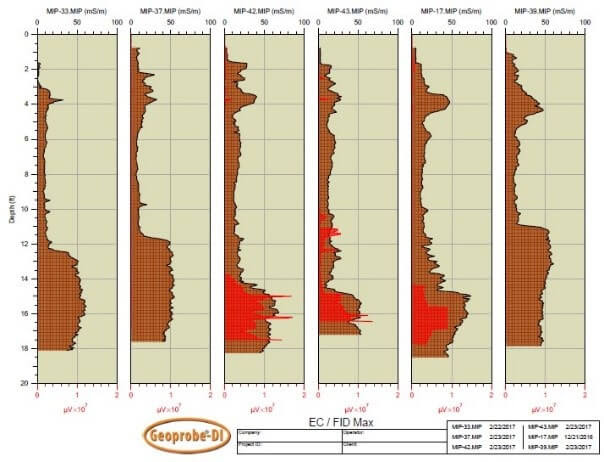

(3) The FID (red) displays a much higher signal in the TCE DNAPL compared to the dissolved phase adjacent to it. This higher FID signal helps to pinpoint the location of DNAPL in the cross section. (4) During this study, we observed the MIP pressure graph may show a slight rise in pressure during this study that when the membrane is exposed to DNAPL. This is a result of NAPL increasing the vapor density of carrier gas stream as it moves through the trunkline to the detectors. This observation requires a very stable MIP pressure prior to encountering the DNAPL zone. This can be seen in the graphs below:

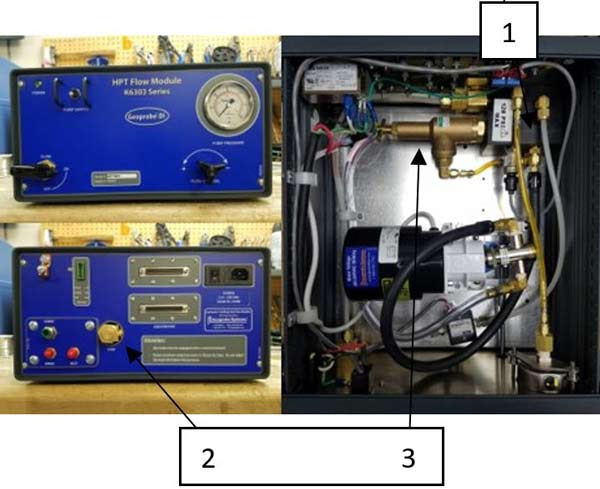

Slight increase in MIP pressure when NAPL is encountered. (5) Expecting DNAPL? Adjust your detector gain settings to low (SRI -PID, FID and OI XSD with appropriate attenuation setting) prior to beginning the log. At these levels you would not need to change them in the ground. You might start out with a bit more detector signal noise, but this will not matter once you reach high dissolved phase concentrations and beyond.

GC Gain/Range settings and associated software multipliers.

|

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842