8150LS Sonic Drill Rig

Video: Geoprobe® 8150LS Sonic Drilling Rig Overview

Maximize Output in Mixed Formations

Drillers seeking to handle tough site conditions with a single drill rig while preserving the option for sampling and setting wells rely on the 8150LS sonic drilling rig to quickly provide continuous, undisturbed core samples to impressive depths in a wide range of formations. Additional advantages of the sonic drilling rig include:

- Production power from 50,000-pound dynamic force GV5 sonic head, which comes with a 3-year/1,000-hour warranty

- Operator safety from the adjustable swing arm control panel and rod handler

- Expert support via remote diagnostics and a dedicated team of sonic experts

- Pair with SRC30DT rod carrier, rod handler, and indexing rack options to create virtually hands-free operation.

New sonic operators will appreciate the quick learning curve and the comprehensive sonic drill rig training offered by our sonic team – all with years of experience training new operators. Regardless the complexity of the question or the experience of the driller, Geoprobe® sonic drilling rig owners depend on our dedicated team of sonic experts for rapid troubleshooting and training.

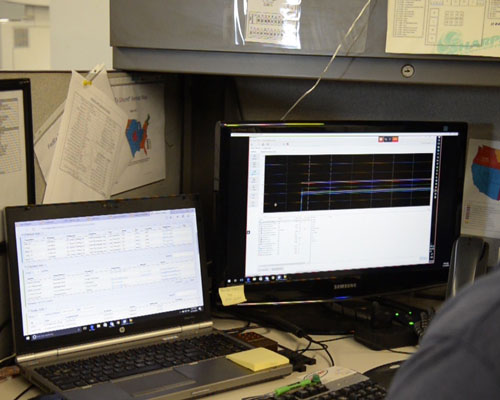

Drill Rig Telemetry

Use NEW drill rig telemetry to view live data from your machines. Monitor rig location, hours, fuel use, and error codes without leaving the office. Stay ahead of maintenance and track performance to keep every rig at its best.

Features & Options

Video: Geoprobe® 8150LS Walkaround

Successfully apply sonic drilling rig power to a broad spectrum of applications, in a wide variety of conditions - from hard rock to soft sediment.

Owners praise their Geoprobe® sonic drilling rig for faster, safer production providing better unconsolidated sample data. With many highly productive features and configurations for success, two-man crews use the 8150LS sonic drilling rig to collect high-quality samples and complete multiple applications in a single boring, using 10-foot tooling up to 12-inch diameter. Pair the 8150LS with the SRC30DT rod carrier, rod handler, and indexing rack options to create a virtually hands-free operation.

- SAMPLING: whether in consolidated materials, glacial till, or backfill rubble, quickly complete complex holes to greater depths with the powerful GV5 50K sonic head. Maintain mast and machine position leveraging the dual pivoting winch and head centerline side shift to guide the GV5 head, automatic drop hammer, or coring head to align with the borehole.

- SAFETY: instead of handling large tooling, rely on the rod handler and indexing rack to minimize heavy lifting – reducing fatigue and injury while increasing productivity. Steer clear of spinning tool strings or position comfortably close to align rods with the adjustable swing arm control panel.

- SUPPORT: regardless the complexity of the question or the experience of the driller, depend on a dedicated team of sonic experts for troubleshooting and training. Should something go awry, remote diagnostics mean assistance is a phone call away. Built-in redundancies on key components add another layer of reassurance for finishing the day and addressing an issue at a more convenient time.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have industry-leading sonic drilling rig service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your sonic drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new sonic drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Version 3 Enhancements

Features to increase field reliability to reduce operational cost

- Breakout with increased clamp and twist force and improved serviceability

- Next generation controls on adjustable height control panel

- Features to increase field reliability to reduce operational cost

- GV5 sonic head now with 3-year/1,000-hour warranty

You can now update your legacy Geoprobe® sonic rig with some of the new features available on the 8150LS V3. Refresh your current rig for enhanced productivity and operator ease. Contact Doug Koehler, sonic expert, to learn more about options for your model.

Geoprobe® GV5 Sonic Head

Through continual innovation, Geoprobe® engineers designed the GV5 Sonic Head to pack both power and a robust head life.

Video: Geoprobe® 8150LS - GV5 Sonic Head

Designed and manufactured by Geoprobe®, the 50,000-pound dynamic force has the power to advance up to 12-inch tooling. And with 4,000 ft-lbf at 90 rpm, the 2-speed rotary drive has the torque needed to maintain rotation in tight formations. Comes with a 3-year/1,000-hour warranty.

The GV5 sonic head includes a centerline side shift function, which moves the head to the side so you can work inside the tool string without moving the mast or re-positioning the machine. This allows the driller to easily access the casing with the dual pivoting winch mast.

DMR7 Rotary Head

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

5,250 ft-lb torque and 1,000 rpm

Eliminate downtime and logistics of casing off overburden, moving your sonic rig, and bringing in another rig for deep rock coring. With the 8150LS and DMR7 rotary head, do it all with one machine posessing torque for mud rotary and speed for diamond coring.

Dual GV5 and 4-speed DMR7 head gives the 8150LS flexibility to switch between sonic, mud or air rotary drilling, and diamond core drilling as geology or scope of work changes — maximizing productivity, reducing mobilization costs, and keeping projects moving with one versatile rig.

High Speed Coring Head for Sonic

Switch from sonic drilling to high speed coring with option coring head along centerline.

Video: Geoprobe® 8150LS - Coring Head

The switchover from sonic to high-speed coring is easy, taking less than five minutes in the field.

The optional coring head mounts onto the side of the GV5 sonic head, moving into place by side shifting the head. The coring head is capable of 800 rpm with 540 ft-lbs of torque in forward and 720 ft-lbs of torque in reverse for breaking tool joints.

Also, the high-speed coring head incorporates a side-feed swivel, and is setup to work with our floating subs. The floating subs have 2 inches of travel simplifying make-up with the tool string. Thread options include: AWJ, NWJ, NWL, HWL, or PWL connections.

Geoprobe® Rod Handling System

Increase productivity and safety, reduce fatigue and injury with 8150LS sonic drilling rig rod handling system.

Video: Geoprobe® 8150LS - Sonic Rod Handling System

Reduce fatigue and injury while increasing productivity and safety with the optional rod handling system. Handles large diameter, 5- and 10-foot rods and casing, minimizing heavy lifting. Adjustable angles permit precise head alignment.

Pairing with optional SRC30DT self-propelled rod carrier or one of the many indexing rack options creates a nearly hands-free operation without sacrificing drilling performance.

Engineered to handle multiple rod and casing sizes, drillers can operate the rod handler from the driller's platform minimizing manpower required on job site. Uneven terrain or the amount of mud on the rod doesn't prohibit performance.

Auto Drop Hammer Compatible (SPT)

Automatic drop hammer along same centerline for efficient production.

An optional automatic drop hammer can be mounted onto the head carrier next to the sonic head. The drop hammer can be accessed independently at any time by side shifting over the tool string.

Dual Winch System

Secondary winch option for weighted wireline includes 1,800 lbs of line pull and quick change hook.

Video: Geoprobe® 8150LS - Winches

The standard winch on the 8150LS has 100 feet of 5/16-inch cable and has 2,500 lbs. of line pull. The optional secondary winch (1/4-inch cable) is capable of 1,800 lbs. of line pull and has a capacity of 425 feet. It is also equipped with a quick change, which allows you to switch from a hook to an overshot.

Or switch to the 950- and 1,600-foot wireline winch which makes retrieving casing from greater depths easy. With more horsepower, higher rpm, and advanced pump capacity, customers are drilling sonic borings deeper than ever.

14-inch Double Wrench Breakout

Double wrench breakout on 8150LS sonic drilling rig makes quick work of breaking tool strings.

Video: Geoprobe® 8150LS - Breakout

Geoprobe® engineers designed a new robust breakout to improve the ability to handle a range of tooling diameters from 2- to 14-inch casing. The new design also incorporates:

- increased clamp force from 21,000 to 31,000 lbf

- increased twist force from 13,500 to 37,000 ft-lb

The re-engineered breakout also improves serviceability because common wear components can be replaced versus needing to replace the entire breakout.

Adjustable Swing-Arm Control Panel

Drillers stay clear of spinning tools strings while enabling easy sight lines on 8150LS sonic drilling rig

Video: Geoprobe® 8150LS - Control Panel

Position yourself comfortably close to align rods or safely away from spinning tool strings with the adjustable swing arm control panel. It features an intuitive layout that allows the operator to perform multiple tasks effortlessly. Speeds, feeds, and pumps can be precisely dialed in with the electronic controls.

An integrated systems display on the control panel provides real-time monitoring of machine parameters and a suite of built-in diagnostic tools. The control panel features an operator presence bar and emergency stop for added safety. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Next generation controls now include a larger display, increased readability, and simplified weight-on-bit.

Front and Rear Outriggers (Four Point Stabilization)

Outriggers add stability to the 8150LS sonic drilling rig

Front and rear outriggers on the 8150LS are adjustable and allow the operator to help stabilize and level the machine on unlevel terrain.

Head Centerline Side Shift, Extend, Drill Mast Dump, Breakout Vertical Shift, Drill Mast Side-Shift

Flexible positioning of mast enables angle boring with the 8150LS sonic drilling rig

Video: Geoprobe® 8150LS - Drill Mast Movements

Eliminate the need to move mast or machine to align with borehole. Works in combination with dual pivoting winch mast to easily access top of casing. Makes optional automatic drop hammer and coring head independently accessible.

The centerline side shift function moves the head side-to-side so you can work inside the diameter of the rod without moving the foot or repositioning the machine.

Fits in a 40-foot Shipping Container

8150LS sonic drilling rig fits inside 40-foot shipping container for easy international transportation

Easily ship the 8150LS sonic drilling rig worldwide tracking it fully assembled (complete with rod handler and sonic head) into a 40-foot shipping container.

Remote Diagnostics

Service support through remote diagnostics for 8150LS repair assistance from anywhere

Integrated systems display provides real-time analysis and built-in diagnostic tools so our sonic team can remotely troubleshoot. Built-in redundancy on key components means finishing the day and addressing the issue at a convenient time.

Features & Options

Video: Geoprobe® 8150LS Walkaround

Owners praise their Geoprobe® sonic drilling rig for faster, safer production providing better unconsolidated sample data. With many highly productive features and configurations for success, two-man crews use the 8150LS sonic drilling rig to collect high-quality samples and complete multiple applications in a single boring, using 10-foot tooling up to 12-inch diameter. Pair the 8150LS with the SRC30DT rod carrier, rod handler, and indexing rack options to create a virtually hands-free operation.

- SAMPLING: whether in consolidated materials, glacial till, or backfill rubble, quickly complete complex holes to greater depths with the powerful GV5 50K sonic head. Maintain mast and machine position leveraging the dual pivoting winch and head centerline side shift to guide the GV5 head, automatic drop hammer, or coring head to align with the borehole.

- SAFETY: instead of handling large tooling, rely on the rod handler and indexing rack to minimize heavy lifting – reducing fatigue and injury while increasing productivity. Steer clear of spinning tool strings or position comfortably close to align rods with the adjustable swing arm control panel.

- SUPPORT: regardless the complexity of the question or the experience of the driller, depend on a dedicated team of sonic experts for troubleshooting and training. Should something go awry, remote diagnostics mean assistance is a phone call away. Built-in redundancies on key components add another layer of reassurance for finishing the day and addressing an issue at a more convenient time.

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have industry-leading sonic drilling rig service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your sonic drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new sonic drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

- Breakout with increased clamp and twist force and improved serviceability

- Next generation controls on adjustable height control panel

- Features to increase field reliability to reduce operational cost

- GV5 sonic head now with 3-year/1,000-hour warranty

You can now update your legacy Geoprobe® sonic rig with some of the new features available on the 8150LS V3. Refresh your current rig for enhanced productivity and operator ease. Contact Doug Koehler, sonic expert, to learn more about options for your model.

Designed and manufactured by Geoprobe®, the 50,000-pound dynamic force has the power to advance up to 12-inch tooling. And with 4,000 ft-lbf at 90 rpm, the 2-speed rotary drive has the torque needed to maintain rotation in tight formations. Comes with a 3-year/1,000-hour warranty.

The GV5 sonic head includes a centerline side shift function, which moves the head to the side so you can work inside the tool string without moving the mast or re-positioning the machine. This allows the driller to easily access the casing with the dual pivoting winch mast.

Video: Geoprobe® 8150LS - GV5 Sonic Head

5,250 ft-lb torque and 1,000 rpm

Eliminate downtime and logistics of casing off overburden, moving your sonic rig, and bringing in another rig for deep rock coring. With the 8150LS and DMR7 rotary head, do it all with one machine posessing torque for mud rotary and speed for diamond coring.

Dual GV5 and 4-speed DMR7 head gives the 8150LS flexibility to switch between sonic, mud or air rotary drilling, and diamond core drilling as geology or scope of work changes — maximizing productivity, reducing mobilization costs, and keeping projects moving with one versatile rig.

The switchover from sonic to high-speed coring is easy, taking less than five minutes in the field.

The optional coring head mounts onto the side of the GV5 sonic head, moving into place by side shifting the head. The coring head is capable of 800 rpm with 540 ft-lbs of torque in forward and 720 ft-lbs of torque in reverse for breaking tool joints.

Also, the high-speed coring head incorporates a side-feed swivel, and is setup to work with our floating subs. The floating subs have 2 inches of travel simplifying make-up with the tool string. Thread options include: AWJ, NWJ, NWL, HWL, or PWL connections.

Video: Geoprobe® 8150LS - Coring Head

Reduce fatigue and injury while increasing productivity and safety with the optional rod handling system. Handles large diameter, 5- and 10-foot rods and casing, minimizing heavy lifting. Adjustable angles permit precise head alignment.

Pairing with optional SRC30DT self-propelled rod carrier or one of the many indexing rack options creates a nearly hands-free operation without sacrificing drilling performance.

Engineered to handle multiple rod and casing sizes, drillers can operate the rod handler from the driller's platform minimizing manpower required on job site. Uneven terrain or the amount of mud on the rod doesn't prohibit performance.

Video: Geoprobe® 8150LS - Sonic Rod Handling System

An optional automatic drop hammer can be mounted onto the head carrier next to the sonic head. The drop hammer can be accessed independently at any time by side shifting over the tool string.

The standard winch on the 8150LS has 100 feet of 5/16-inch cable and has 2,500 lbs. of line pull. The optional secondary winch (1/4-inch cable) is capable of 1,800 lbs. of line pull and has a capacity of 425 feet. It is also equipped with a quick change, which allows you to switch from a hook to an overshot.

Or switch to the 950- and 1,600-foot wireline winch which makes retrieving casing from greater depths easy. With more horsepower, higher rpm, and advanced pump capacity, customers are drilling sonic borings deeper than ever.

Video: Geoprobe® 8150LS - Winches

Geoprobe® engineers designed a new robust breakout to improve the ability to handle a range of tooling diameters from 2- to 14-inch casing. The new design also incorporates:

- increased clamp force from 21,000 to 31,000 lbf

- increased twist force from 13,500 to 37,000 ft-lb

The re-engineered breakout also improves serviceability because common wear components can be replaced versus needing to replace the entire breakout.

Video: Geoprobe® 8150LS - Breakout

Position yourself comfortably close to align rods or safely away from spinning tool strings with the adjustable swing arm control panel. It features an intuitive layout that allows the operator to perform multiple tasks effortlessly. Speeds, feeds, and pumps can be precisely dialed in with the electronic controls.

An integrated systems display on the control panel provides real-time monitoring of machine parameters and a suite of built-in diagnostic tools. The control panel features an operator presence bar and emergency stop for added safety. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised.

Next generation controls now include a larger display, increased readability, and simplified weight-on-bit.

Video: Geoprobe® 8150LS - Control Panel

Front and rear outriggers on the 8150LS are adjustable and allow the operator to help stabilize and level the machine on unlevel terrain.

Eliminate the need to move mast or machine to align with borehole. Works in combination with dual pivoting winch mast to easily access top of casing. Makes optional automatic drop hammer and coring head independently accessible.

The centerline side shift function moves the head side-to-side so you can work inside the diameter of the rod without moving the foot or repositioning the machine.

Video: Geoprobe® 8150LS - Drill Mast Movements

Easily ship the 8150LS sonic drilling rig worldwide tracking it fully assembled (complete with rod handler and sonic head) into a 40-foot shipping container.

Integrated systems display provides real-time analysis and built-in diagnostic tools so our sonic team can remotely troubleshoot. Built-in redundancy on key components means finishing the day and addressing the issue at a convenient time.

“I had heard stories of sonic rigs with so many problems, but I’ve never had a major problem. And if I do have a minor problem, Geoprobe® service is quick to respond. I don’t have a lot of down time with this machine. Even with competitors continually trying to sell me their sonic drilling rig, if I buy another sonic, it will be a Geoprobe® because the service is great.”

- Firas Mishu, President, M&W Drilling, Tennessee

Tooling & Accessories

Two-piece design allows versatility to pin up or pin down or to just replace the coupler. Breakout flats on the coupler minimize wear on the jaw pads when breaking tool joints apart. Rounded pin joint speeds up the stabbing of joints together for a faster connection. Larger tool joint cross section helps strengthen rod, maximizing overall thread life.

Video: Geoprobe® 6x8 Sonic Sampling

6x8 sonic sampling provides the operator a larger area to work with than the traditional 4x6 method. The operator can obtain a larger diameter sample if desired, but this casing combination is typically used to provide a larger hole, such as to set a monitoring well. When telescoping one casing over another it is important to consider your main objective to determine sampling size.

The 8x10 sonic sampling system is the largest of our conventional sonic sampling systems. The Geoprobe® sonic casing family has been uniquely designed so that each incremental casing size works efficiently with the next. In this case, you will have the size needed to remove even more material from the subsurface.

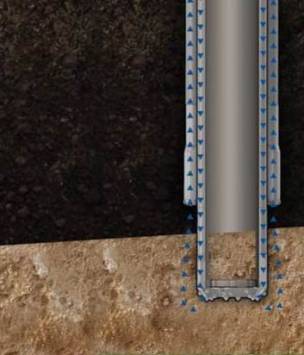

Video: Geoprobe® SDT45 Sonic Sampling

Sonic Dual Tube 45 (SDT45) is a unique and versatile sampling system advancing an outer casing and an inner soil sampler simultaneously. The SDT45 sample (3.0 in. diameter) is collected in a clear PVC liner providing a high-quality representative sample. The 4.5-inch outer casing remains in the ground (cased hole) while the sample is retrieved with inner 2.25-inch. probe rods. The system provides optional bits based upon geologic conditions (soils and rock) for more efficient sampling and recovery. The versatile SDT45 system can be used for many applications including, environmental sampling, varying types of well installations, cased hole applications, geotechnical borings, and exploration projects of numerous types.

Video: Geoprobe® Sonic Double Wall 4.5 in. (SDW45)

The Sonic Double Wall 45 (SDW45) System compliments conventional Sonic 4x6 system to obtain critical confirmatory rock or bedrock samples at the end of a boring, whether Sonic 4x6 or SDT45 is used. Used for environmental, geotechnical, mineral explorations, and most projects where 4x6 is used, it can also be used in place of traditional sonic dual tube system when angled drilling is required.

The SP60 Sonic Groundwater Sampler is a packer based, deployable sampling system designed for collecting groundwater samples through Geoprobe® 6-inch casing. The system includes an inflatable packer, 2-inch stainless steel screen, and an inflation manifold assembly. The assembly is commonly deployed inside 6-inch casing with standard 2-inch schedule 40 PVC. The packer is inflated via flexible tubing, inflation valve assembly, and air supply (not included). Manual air pumps or a small air tank are common sources for the compressed air needed to inflate the packer.

Video: Indexing Rack for 10-foot Sonic Tooling

With a few basic movements and one ‘touch’ of the drill stem, sonic tooling can be loaded into the rig’s rod loader, and the machine’s functions take over. The same can be said when tripping rods out of the borehole. The machine-based rod loader lowers the tooling to a position where once again a few basic movements and one ‘touch’ of the casing puts the tool safely back into the indexing rack until it’s needed for the next interval. The rack is adapatable to run 3.5-inch to 10-inch sonic casing in 10-foot lengths.

Video: Geoprobe® Spring Assisted Swivel Lift Cap

The Spring Assisted Swivel Lift Cap is designed to reduce operator fatigue when adding or removing sections of rods to the inner tool string. The internal springs of the pull cap bear the weight of the rod string. With minimal effort, the operator can adjust the rod string up or down when threading or unthreading the rods. The natural self-alignment of the rod string prevents tipping off center and binding of the threads.

Applications

Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

ID: 12781

Geoprobe® 8150LS Sonic Overview

ID: 1927

ID: 1922

Geoprobe® 8150LS - Control Panel

ID: 1923

ID: 1929

Geoprobe® 8150LS - Coring Head

ID: 1924

High-Speed Coring Head for Sonic

ID: 1886

ID: 262

Specs

Specifications are subject to change without notice.

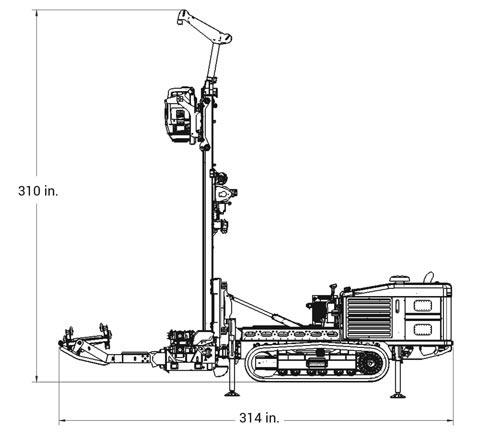

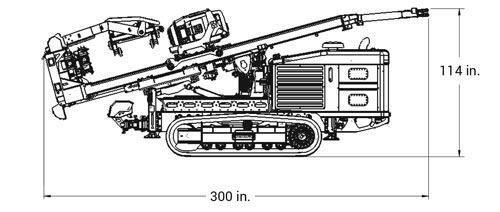

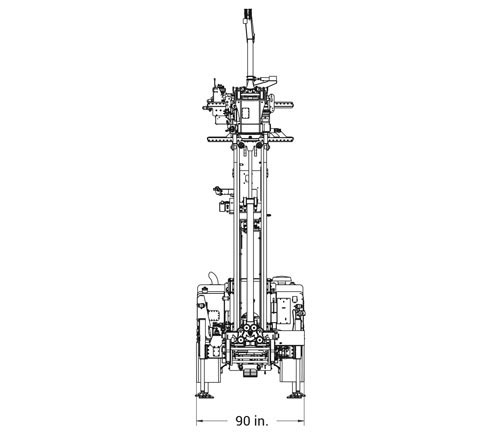

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 90 | Width (mm) | 2286 |

| Length (transport) (in) | 300 | Length (transport) (mm) | 7620 |

| Length (transport) (ft) | 25.0 | Length (transport) (m) | 7.62 |

| Length (deployed, lateral fully retracted) (in) | 240 | Length (deployed, lateral fully retracted) (mm) | 6096 |

| Length (deployed, lateral fully retracted with rod handler deployed) (in) | 314 | Length (deployed, lateral fully retracted with rod handler deployed) (mm) | 7976 |

| Height (normal transport) (in) | 114 | Height (normal transport) (mm) | 2896 |

| Height (deployed; winch mast up) (in) | 310 | Height (deployed; winch mast up) (mm) | 7874 |

| Height (deployed; winch mast up) (ft) | 25.8 | Height (deployed; winch mast up) (m) | 7.87 |

| Height (min standard working height) (in) | NA | Height (min standard working height) (mm) | NA |

| Approach/departure angle in transport (degrees) | 24 | Approach/departure angle in transport (degrees) | 24 |

| Base Unit Weight (lbs) | 32,500 | Base Unit Weight (kg) | 14,742 |

| Unit Weight (w/ typical options) lbs | 33,500 | Unit Weight (w/ typical options) kg | 15,195 |

| Ground Speed (mph) | 1.5 | Ground Speed (kph) | 2.4 |

| Estimated Track Surface Area (in2) | 3546 | ||

| Estimated Ground Pressure (psi) | 9.2 | ||

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 6 | Extension (fore and aft) (mm) | 152 |

| Drill Mast Dump (in) | 36 | Drill Mast Dump (mm) | 914 |

| front outrigger travel (in) | 26 | front outrigger travel (mm) | 660 |

| rear outrigger travel (in) | 26 | rear outrigger travel (mm) | 660 |

| Max angle drilling ability off vertical (degrees) | 45 | Max angle drilling ability off vertical (degrees) | 45 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 157 | Head Travel (mm) | 3988 |

| Head Travel (ft) | 13.1 | Head Travel (m) | 3.99 |

| Head Crowd Force (lbs) | 11,000 | Head Crowd Force (kN) | 49 |

| Head Pull Force (lbs) | 20,000 | Head Pull Force (kN) | 89 |

| Head Feed Carriage | Rollers | Head Feed Carriage | Rollers |

| Head Feed Pressure Control (w.o.b) | Standard | Head Feed Pressure Control (w.o.b) | Standard |

| Head Sideshift (in) | 32 | Head Sideshift (mm) | 813 |

| Head tilt out: (degrees) | 90 | Head tilt out: (degrees) | 90 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | CAT C7.1 Tier 4 final or Tier 3(LRC) | Engine | CAT C7.1 Tier 4 final or Tier 3(LRC) |

| Engine Rated Power (hp) | 275 | Engine Rated Power (kW) | 205 |

| Fuel Capacity (gal) | 90 | Fuel Capacity (L) | 341 |

| Sonic head | GV5 | Sonic head | GV5 |

| Max oscillator speed (Hz) | 150 | Max oscillator speed (Hz) | 150 |

| Dynamic force @ max oscillator speed (lbf) | 50,000 | Dynamic force @ max oscillator speed (kN) | 222 |

| Rotation Torque (Range 1) (ft-lb) | 4000 | Rotation Torque (Range 1) (N-m) | 5423 |

| Rotation Speed (Range 1) (rpm) | 90 | Rotation Speed (Range 1) (rpm) | 90 |

| Rotation Torque (Range 2) (ft-lb) | 2500 | Rotation Torque (Range 2) (N-m) | 3390 |

| Rotation Speed (Range 2) (rpm) | 140 | Rotation Speed (Range 2) (rpm) | 140 |

| Standard Winch | Standard Winch | ||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 |

| line speed (fpm) | 125 | line speed (m/min) | 38 |

| cable length (ft) | 100 | cable length (m) | 30 |

| Secondary Winch | Secondary Winch | ||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 145 | line speed (m/min) | 44 |

| cable length (ft) | 425 | cable length (m) | 130 |

| Wireline Winch | Wireline Winch | ||

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 375 | line speed (m/min) | 114 |

| cable length (ft) | 1600 | cable length (m) | 488 |

| Triplex Water Pump | Triplex Water Pump | ||

| Max pressure (psi) | 750 | Max pressure (bar) | 52 |

| Max flow (gpm) | 70 | Max flow (L/min) | 265 |

| Breakout | Breakout | ||

| Max Clamp force (lbf) | 31,000 | Clamp force (kN) | 137.89 |

| Breakout torque (ft-lb) | 37,000 | Breakout torque (N-m) | 50168 |

| Min Casing size compatible (in) | 2 | Min Casing size compatible (mm) | 51 |

| Max Casing size compatible (in) | 14 | Max Casing size compatible (mm) | 356 |

| Vertical travel (in) | 9 | Vertical travel (mm) | 229 |

| Rod Handler | Rod Handler | ||

| Min Casing size compatible (in) | 3.5 | Min Casing size compatible (mm) | 89 |

| Max Casing size compatible (in) | 9.63 | Max Casing size compatible (mm) | 245 |

| Arm travel (degrees) | 163 | Arm travel (degrees) | 163 |

| Wrist travel (degrees) | 38 | Wrist travel (degrees) | 38 |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 90 | Width (mm) | 2286 |

| Length (transport) (in) | 300 | Length (transport) (mm) | 7620 |

| Length (transport) (ft) | 25.0 | Length (transport) (m) | 7.62 |

| Length (deployed, lateral fully retracted) (in) | 240 | Length (deployed, lateral fully retracted) (mm) | 6096 |

| Length (deployed, lateral fully retracted with rod handler deployed) (in) | 314 | Length (deployed, lateral fully retracted with rod handler deployed) (mm) | 7976 |

| Height (normal transport) (in) | 114 | Height (normal transport) (mm) | 2896 |

| Height (deployed; winch mast up) (in) | 310 | Height (deployed; winch mast up) (mm) | 7874 |

| Height (deployed; winch mast up) (ft) | 25.8 | Height (deployed; winch mast up) (m) | 7.87 |

| Height (min standard working height) (in) | NA | Height (min standard working height) (mm) | NA |

| Approach/departure angle in transport (degrees) | 24 | Approach/departure angle in transport (degrees) | 24 |

| Base Unit Weight (lbs) | 32,500 | Base Unit Weight (kg) | 14,742 |

| Unit Weight (w/ typical options) lbs | 33,500 | Unit Weight (w/ typical options) kg | 15,195 |

| Ground Speed (mph) | 1.5 | Ground Speed (kph) | 2.4 |

| Estimated Track Surface Area (in2) | 3546 | ||

| Estimated Ground Pressure (psi) | 9.2 | ||

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 6 | Extension (fore and aft) (mm) | 152 |

| Drill Mast Dump (in) | 36 | Drill Mast Dump (mm) | 914 |

| front outrigger travel (in) | 26 | front outrigger travel (mm) | 660 |

| rear outrigger travel (in) | 26 | rear outrigger travel (mm) | 660 |

| Max angle drilling ability off vertical (degrees) | 45 | Max angle drilling ability off vertical (degrees) | 45 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 157 | Head Travel (mm) | 3988 |

| Head Travel (ft) | 13.1 | Head Travel (m) | 3.99 |

| Head Crowd Force (lbs) | 11,000 | Head Crowd Force (kN) | 49 |

| Head Pull Force (lbs) | 20,000 | Head Pull Force (kN) | 89 |

| Head Feed Carriage | Rollers | Head Feed Carriage | Rollers |

| Head Feed Pressure Control (w.o.b) | Standard | Head Feed Pressure Control (w.o.b) | Standard |

| Head Sideshift (in) | 32 | Head Sideshift (mm) | 813 |

| Head tilt out: (degrees) | 90 | Head tilt out: (degrees) | 90 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | CAT C7.1 Tier 4 final or Tier 3(LRC) | Engine | CAT C7.1 Tier 4 final or Tier 3(LRC) |

| Engine Rated Power (hp) | 275 | Engine Rated Power (kW) | 205 |

| Fuel Capacity (gal) | 90 | Fuel Capacity (L) | 341 |

| Sonic head | GV5 | Sonic head | GV5 |

| Max oscillator speed (Hz) | 150 | Max oscillator speed (Hz) | 150 |

| Dynamic force @ max oscillator speed (lbf) | 50,000 | Dynamic force @ max oscillator speed (kN) | 222 |

| Rotation Torque (Range 1) (ft-lb) | 4000 | Rotation Torque (Range 1) (N-m) | 5423 |

| Rotation Speed (Range 1) (rpm) | 90 | Rotation Speed (Range 1) (rpm) | 90 |

| Rotation Torque (Range 2) (ft-lb) | 2500 | Rotation Torque (Range 2) (N-m) | 3390 |

| Rotation Speed (Range 2) (rpm) | 140 | Rotation Speed (Range 2) (rpm) | 140 |

| Standard Winch | Standard Winch | ||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 |

| line speed (fpm) | 125 | line speed (m/min) | 38 |

| cable length (ft) | 100 | cable length (m) | 30 |

| Secondary Winch | Secondary Winch | ||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 145 | line speed (m/min) | 44 |

| cable length (ft) | 425 | cable length (m) | 130 |

| Wireline Winch | Wireline Winch | ||

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 375 | line speed (m/min) | 114 |

| cable length (ft) | 1600 | cable length (m) | 488 |

| Triplex Water Pump | Triplex Water Pump | ||

| Max pressure (psi) | 750 | Max pressure (bar) | 52 |

| Max flow (gpm) | 70 | Max flow (L/min) | 265 |

| Breakout | Breakout | ||

| Max Clamp force (lbf) | 31,000 | Clamp force (kN) | 137.89 |

| Breakout torque (ft-lb) | 37,000 | Breakout torque (N-m) | 50168 |

| Min Casing size compatible (in) | 2 | Min Casing size compatible (mm) | 51 |

| Max Casing size compatible (in) | 14 | Max Casing size compatible (mm) | 356 |

| Vertical travel (in) | 9 | Vertical travel (mm) | 229 |

| Rod Handler | Rod Handler | ||

| Min Casing size compatible (in) | 3.5 | Min Casing size compatible (mm) | 89 |

| Max Casing size compatible (in) | 9.63 | Max Casing size compatible (mm) | 245 |

| Arm travel (degrees) | 163 | Arm travel (degrees) | 163 |

| Wrist travel (degrees) | 38 | Wrist travel (degrees) | 38 |

Operator Side - Unfolded

Operator Side - Folded

Front - Unfolded

Resources

Click on a section below to view information.

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

ID: 14598 | Date:

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

Geoprobe® manufactured 3.5 and 6.0 sonic casing.

ID: 14596 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.