First Job. The AEAC Field Team took advantage of the adjustability of the hose pump and water swivel on the 3230DT to core through 20-in. thick concrete flooring inside an aerospace metal recycling facility.

New paint. So it was no surprise that the arrival of a new Geoprobe® 3230DT Combo Rig at the American Environmental Assessment Corp. facility in Hartford, CT, in late fall had the guys pumped! They were the first in the area to welcome the newest machine model from Geoprobe Systems®. After a few hours of orientation and training, and a celebratory barbeque lunch from Bears, the ‘fun’ was about to begin!

According to Dirk Barry, AEAC General Manager, the rig’s first project required coring twenty 10-in. diameter holes through 12-in. thick, rebar-reinforced concrete to pre-clear drilling locations for potential utilities. “The client, a major oil company, thought the rotational guard on the rig was a real safety feature,” Barry said. The drilling crew liked the ability to set the rotational speed to the core bore. “Ideal rotational speed of 318 rpm provides the best cutting speed,” Barry added, “and adds to the life of the bit.”

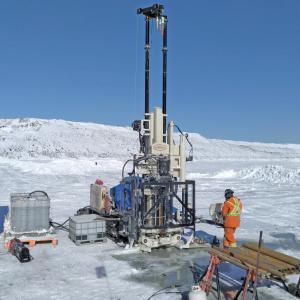

No cuttings pleases client. Then it was on to a large aerospace metal recycling facility (above) to core through a 20-in. thick concrete floor where the rig and crew were surrounded by “mountains” of titanium and nickel shavings. “The 3230DT muscled right through the concrete,” Barry explained. “The hose pump worked great. The guys liked how it could be dialed down to allow just the right flow of water for cooling the core bit. We then drove 4.5-in. tooling to 20 feet with an expendable point and installed, 2-in. monitoring wells. The client really appreciated the fact that no soil cuttings were generated on the shop floor.”

“The more we used the rig the more we realized how powerful it was,” Barry continued. The AEAC Field Team used the 3230DT to abandon an old 10-in. diameter, turbine, shaft-driven production well. The work required that the pump motor and 4-in. diameter impeller shaft be removed from the 10-in. well. The impeller extended to 110 ft. below grade. “The 5,000 lb. capacity winch and 20-ft. mast were helpful in pulling the pump motor and tripping out the impeller shaft,” Barry explained. “Even the breakout table was extremely helpful in holding the shaft as each section was cut.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

ID: 14359 | Date:

The East Coast Service Team works hard to keep companies like Odyssey Environmental Services in the field as much as possible.

ID: 14031 | Date:

Geoprobe® manufactures high quality tooling by listening to customer feedback and continuing to innovate.

ID: 14027 | Date:

Driller praises the power and smoothness of the 3230DT when coring rock.

ID: 14019 | Date:

Related Videos

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 5550

ID: 1955

ID: 220