Articles

What do owners think about their Geoprobe® drill rig? Check out some of the stories below to learn how their rigs helped them achieve success and perhaps discover how a Geoprobe® drill rig could spark the next step in your own environmental, geotechnical, exploration, geothermal, and water well drilling business growth.

Telemetry Service: Real-time Drill Rig Insights

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

Dynamic Driller Winter 2025

From High School Job to Family Well Drilling Business

Refurbished Schramm T450 outperforms expectations for family-owned drilling company.

ID: 14624 | Date:

Dynamic Driller Winter 2025

Driltech Downtime to Drill Time

Used Driltech rig receives multiple service sessions to stay field-ready for the long term.

ID: 14623 | Date:

Dynamic Driller Winter 2025

60 Day Not 6 Month Drilling Rig Repair

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Dynamic Driller Winter 2025

Reliable Water Well Drilling Rig Truck, Reliable Service

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

Dynamic Driller Winter 2025

125 Years of Tradition Meets Split Spoon Innovation

Geoprobe® interlocking split spoons meet the demands of geotechnical drillers using conventional rigs.

ID: 14620 | Date:

Dynamic Driller Winter 2025

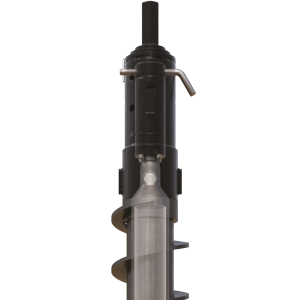

4.25 Hollow Stem Auger Continuous Sampler for Continuous Core Drilling

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

Dynamic Driller Winter 2025

Value Added from High-resolution Site Characterization - Cases from South America

Equipment used and overall operation layout during a MIHPT location.

ID: 14618 | Date:

Dynamic Driller Winter 2025

Expanding Remediation Project Capabilities

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

Dynamic Driller Winter 2025

Small Rig, Strong Results on Injection Point Project

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

Dynamic Driller Winter 2025

Canada Drilling Company Connection to Expert Service Support

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Dynamic Driller Winter 2025

Leveling Up Geotechnical Drilling and Sampling

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date:

Dynamic Driller Winter 2025

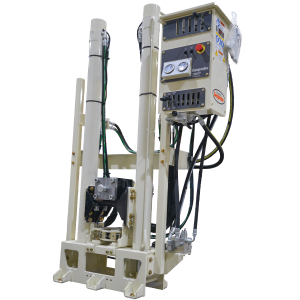

Versatile 20-Ton Rated CPT Drill

The 20CPT Standalone Press can be mounted on any carrier, letting you tailor transport for your fieldwork.

ID: 14607 | Date:

Dynamic Driller Winter 2025

Decades of Drilling, One Trusted Name

7822DT’s power and versatility excel at pushing cones and handling diverse geotechnical tasks like here at a Nike facility in Beaverton, Oregon.

ID: 14606 | Date:

Dynamic Driller Winter 2025

Direct Push to Down the Hole Hammer

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Dynamic Driller Winter 2025

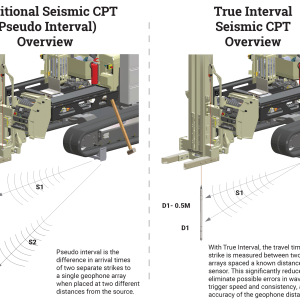

ASTRA True Interval Seismic CPT Testing

With a true interval seismic CPT module, two sensors are positioned exactly 0.5 meters apart, allowing a single hammer strike to be recorded at both depths at the same time.

ID: 14604 | Date:

Dynamic Driller Winter 2025

CPT Technology Brings Efficiency and Excitement

Geoprobe® ASTRA CPT training covers data theory and field application. Its simple interface helps users get field-ready quickly, with Geoprobe® CPT specialists available by phone for troubleshooting.

ID: 14603 | Date:

Dynamic Driller Winter 2025

3135GT Features for Geotechnical Borings

With 10,000 ft lbs of torque and 1,000 rpm, the compact 3135GT delivers job site success with more power.

ID: 14602 | Date:

Dynamic Driller Winter 2025

Rock Coring Methods Power Through Quartz and Granite

Along with extra torque and rpm, 3135GT features like weight-on-bit, hands-free rotation, and three winches make rock coring easier.

ID: 14601 | Date:

Dynamic Driller Winter 2025

Versatile Methods of Drilling to Bid the Big Jobs

Adjusting mast dump to position control panel and using blade to optimize drop rack positioning make the workspace more comfortable.

ID: 14600 | Date:

Dynamic Driller Winter 2025

CDL-Free Truck Rig for Highway Success

The 3100GT makes drilling and transport on highway expansion projects easier with simple operation and no Class A/B CDL needed.

ID: 14599 | Date:

Dynamic Driller Winter 2025

8150LS Options: Rotary Head Maximizes Productivity

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

ID: 14598 | Date:

Dynamic Driller Winter 2025

Rod Handling Drives Sonic Technology Upgrade

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

Dynamic Driller Winter 2025

Industry Compatible: 4X6 Sonic Sampling System

Geoprobe® manufactured 3.5 and 6.0 sonic casing.

ID: 14596 | Date:

Dynamic Driller Winter 2025

Power, Efficiency for Varied Sonic Applications

8150LS V3 provides ergonomic operations while powering through tough formations on a dam project.

ID: 14595 | Date:

Dynamic Driller Winter 2025

From Well Service to Air Rotary Drilling Rig Operator

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

Dynamic Driller Winter 2025

Top Drive Rig Total Game Changer

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

Dynamic Driller Winter 2025

Family Legacy Built with Dual Small Water Well Drills

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date:

Dynamic Driller Winter 2025

Opening up Geothermal Vertical Loop Market

Canadian geothermal energy company chooses DM250 features like size-to-power ratio when expanding into vertical residential, small commercial geothermal installation.

ID: 14590 | Date:

Dynamic Driller Winter 2025

Efficiency Transforms Business Drilling Water Wells

Compact DM250 slips into tight residential lots, satisfying customers particular about their landscaping.

ID: 14589 | Date:

Dynamic Driller Winter 2025

Septic Business Adds Residential Water Wells

Compact footprint of DM450 slips into wooded lots with ease, possessing power to reach depth and pull rods.

ID: 14588 | Date:

Dynamic Driller Winter 2025

DM450: 6X6 All-Wheel Drive

The 6x6 All-Wheel Drive on the Geoprobe® DM450 improves the ability to navigate sandy or muddy job sites.

ID: 14587 | Date:

Dynamic Driller Winter 2025

Environmental Sampling to Geothermal Installation Power

Features like backloading carousel on DM450 provide confidence to tackle large geothermal.