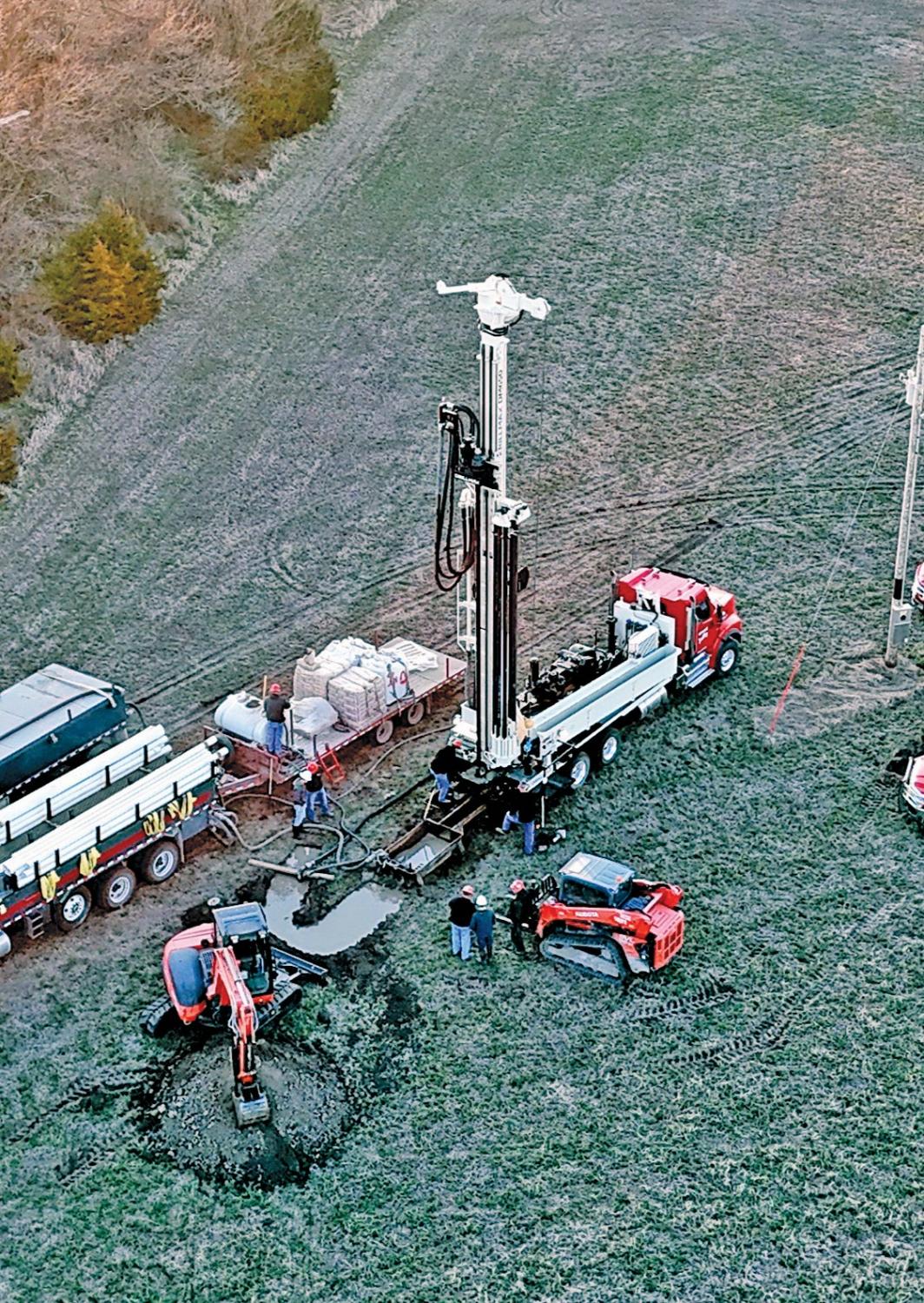

Top drive rig DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

As one of the largest family-owned well drilling companies in the United States, Sargent Drilling got their start doing irrigation wells. They've expanded to municipal wells and industrial engineering from eight offices.

“We drill anywhere from 4-inch, 50-foot wells to 15-inch, 1,000-foot wells – all with the same style rig,” said Nathan Jacobson, operations manager out of the Geneva, Nebraska, office. “We’ve always been a table drive rig company, until we saw a demo of a top head drive rig. Then we decided we wanted two.”

Their pursuit of a top drive rig led them to Geoprobe® manufacturing facilities in Salina, Kansas, to consider the DM series rigs.

“We liked the DM model better, appreciated parts and service center were only two hours away from our shop, and the number of options available on the rig,” Jacobson said. “We actually went to the factory to look at and order our DM650 when we saw the DM250. That’s when the light bulb went on. We were used to drilling everything with one style rig, but we could see the advantage of the smaller unit for our smaller wells.”

They left the factory placing an order for both a DM650 and a DM250.

DM250 — The Game Changer

The DM250’s performance has Jacobson raving.

“I’ve been surprised by the DM250’s versatility, power, and depths it can achieve — it’s an awesome rig,” he said. “It’s a really special rig. Geoprobe® hit a home run with that one.”

Favorite Features

- Ease of Operation: “People who don’t want the responsibility of operating a complex rig are very comfortable operating the DM250 because it's very simple.”

- Carousel and Pipe Handling System: “You don’t have to touch the pipe. It’s basically a one-man show.”

- Safety: “It’s 300-times safer than a table drive rig.”

- Speed: “It doesn’t look like it would be as fast as a table drive rig, but each step of the drilling process is more efficient.”

The Results

Since receiving their DM250, they’ve been able to revolutionize their work.

“With the DM250, we’ve cut drilling times, and we don’t need a CDL driver — that’s huge. It took a drilling rig to rethink our whole program,” Jacobson said. “We’ve now looked at everything we’re doing to make it simpler and more profitable. The DM250 is key to that.”

DM650 — The Workhorse

Sargent has put their DM650 on deep, big diameter wells in northwest Iowa drilling 12- to 14-inch bits 500-600 feet.

“It’s performed magnificently,” Jacobson said. “You can add pipe and keep drilling. You’re drilling as fast and handling pipe less compared to a table drive rig.”

Favorite Features

- Power: “It can manage 4.5-inch pipe and you don’t have to handle it.”

- Ease of Operation: “At the end of a 12-hour day, the crew isn’t exhausted.”

- Backloading Carousel: “The way you can add to the carousel from the drill stem rack is light years ahead of the competition.”

The Verdict: Top Drive Rig vs Table Drive

“We’ve been used to table drive, piston pump rigs. Now we’re top head drive, centrifugal pump, and I can’t believe how well it performs,” Jacobson said. “I’m 61-years-old, and change is hard. But I’ve jumped in the river of change, and I’m enjoying the bath.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date: