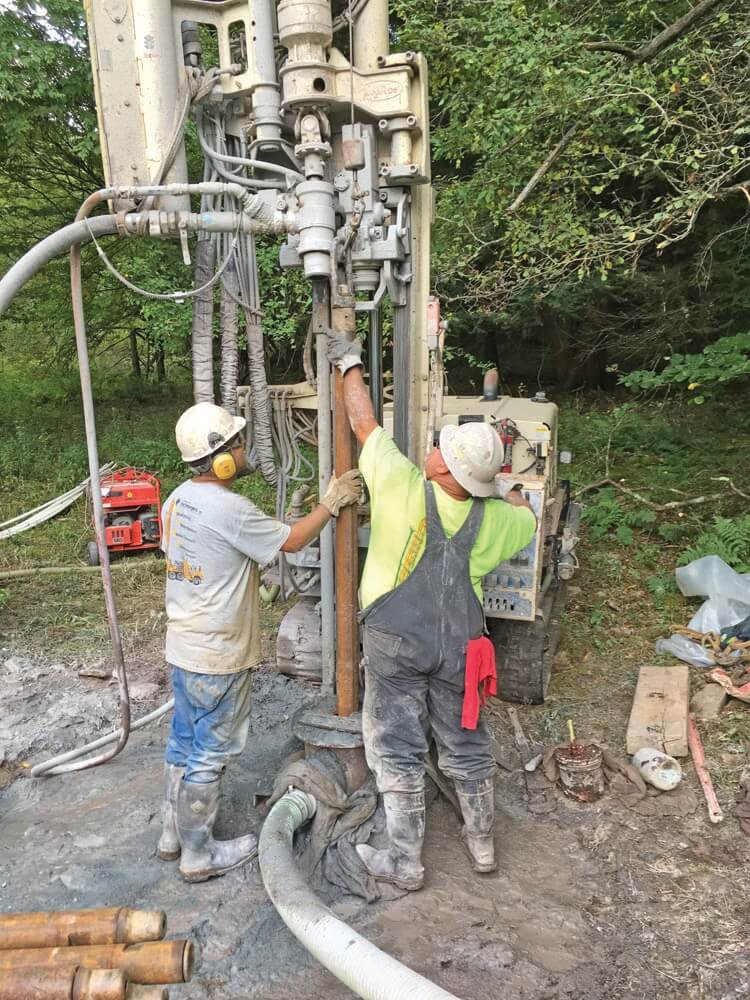

Versatility and mobility make 7822DT go-to rig for completing air rotary.

For some air rotary is a rarity, but for EICHELBERGERS INC in Pennsylvania it’s a weekly occurrence using their 7822DTs. They’ve completed air rotary to 220 feet; they’ve drilled using 8-inch and 10-inch casing. On one project they set 10-inch casing to 60 feet and then air drilled 6-inch casing to 180 feet.

“We completed a gas pipeline project doing air rotary for two years drilling 150- to 200-feet per day with 4-inch hammers,” Chris Chronister, driller, said. “We just completed a job at a military base using air rotary with the 7822DT. We set 10-inch casing then drilled 6-inch casing down to 90 feet for a monitoring well on a PFAS study.”

They find the versatility of the 7822DT to spin augers to bedrock then air rotary ideal for these projects. The ability to track through undisturbed areas, using the blade to move brush out of the way or transport air compressors to remote sites, contributes to choosing the 7822DT for air rotary jobs. They recently used it on a gas pad site coring rock using air.

“They wanted to see where the water was located so didn’t want us to use water to remove the cuttings,” Chronister said. “Using air, the core came out looking like it would if we were using mud.”

They’ve deployed up to four 7822DTs on a job at a time and the clients have always been happy with the progress the 7822DT can accomplish each day.

“The 7822DT will do so many things. We have six conventional rigs, but our Geoprobe® 7822DTs can do everything they do plus air rotary, rock coring, augering, and split spoon,” Chronister said. “We’re able to set up on hole quickly, and if a tracked skid steer can get there, I can get the 7822DT there.”

Drilling 10-inch air rotary with the 7822DT might rattle some bolts, but the backing of Geoprobe® service support provides Chronister confidence despite routinely being assigned their oldest 7822DT.

“When I’ve called in, I’ve become good friends with Bryan Lorenson and Roman Burrows,” Chronister said. “If I’m back in the woods a mile and can’t get the rig started, they’ve always been very good at helping me get from point A to point B. Geoprobe® always provides good support when you’ve got a problem.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date: